Abstract

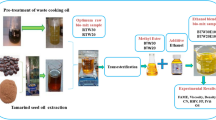

Biodiesel is an alternative fuel that has been used for partial or total substitution of diesel to reduce its environmental impacts. Prior studies on this topic have focused on the quest for better synthesis process, new catalysts and low-cost non-food and raw materials to improve the economic and sustainable production as well as product quality. In this study, acidic oil from macauba, a palm tree native to South America that has no food uses, was converted into biodiesel. The esterification and transesterification reactions were performed with methanol, ethanol and isobutanol with the goal of improving the cold properties of the biodiesel. The isobutyl ester exhibited the lowest freezing point temperature but underperformed outside of international specifications for kinematic viscosity; it also exhibited a low ester content. The methyl and ethyl esters were within the specifications of the international standards for ester content, density, kinematic viscosity and sulphur content. The ethyl ester produced from macauba oil displayed better properties in cold conditions than methyl and isobutyl esters studied here, with a cold filter plugging point of 0 °C. Its onset crystallisation temperature was reduced from −5.96 to −13.41 °C when subjected to fractional crystallisation. The ethyl ester exhibited the best lubricity value among the other esters studied.

Similar content being viewed by others

References

Kouzu M, Hidaka J (2012) Transesterification of vegetable oil into biodiesel catalyzed by CaO: a review. Fuel 93:1–12

Fukuda H, Akihko A, Noda H (2001) Biodiesel fuel production by transesterification of oils. J Biosci Bioeng 92:405–416

Marchetti JM, Miguel VU, Errazu AF (2007) Possible methods for biodiesel production. Renew Sust Energ Rev 11:1300–1311

Shahid EM, Jamal Y (2011) Production of biodiesel: a technical review. Renew Sust Energ Rev 15:4732–4745

Lam MK, Lee KT, Mohamed AR (2010) Homogeneous, heterogeneous and enzymatic catalysis for transesterification of high free fatty acid oil (waste cooking oil) to biodiesel: a review. Biotechnol Adv 28:500–518

Haas MJ, McAloon AJ, Yee WC, Foglia TA (2006) A process model to estimate biodiesel production cost. Bioresour Technol 97:671–678

Tasic MB, Stamenkovic OS, Veljkovic VB (2014) Cost analysis of simulated base-catalyzed biodiesel production processes. Energ Convers Manage 84:405–413

Thaiyasuit P, Pianthong K, Worapun I (2012) Acid esterification-alkaline transesterification process for methyl ester production from crude rubber seed oil. J Oleo Sci 61:81–88

Jansri S, Ratanawilai SB, Allen ML, Prateepchaikul G (2011) Kinetics of methyl ester production from mixed crude palm oil by using acid-alkali catalyst. Fuel Process Technol 92:1543–1548

Canacki M, Gerpen JV (1999) Biodiesel production via acid catalysis, T. ASAE 42:1203–1210

Sinha S, Agarwal AK, Garg S (2008) Biodiesel development from rice bran oil: transesterification process optimization and fuel characterization. Energy Conver Manag 49:1248–1257

Lanes ECM, Costa PMA, Motoike SY (2014) Alternative fuels: Brazil promotes aviation biofuels. Nature 511:31

Henderson A, Galeano G, Bernal R (1995) Field guide to the palms of the Americas. Princeton University Press, New Jersey

Pires TP, Souza ES, Kuki KN, Motoike SY (2013) Ecophysiological traits of the macaw palm: a contribution towards the domestication of a novel oil crop. Ind Crops Prod 44:200–210

Novaes RF (1952) Contribuição para o estudo do coco macaúba [Contribution to the study of the macauba coconut]. Thesis (PhD in Agricultural Sciences), Luiz de Queiroz College of Agriculture, University of Sao Paulo, Brazil

Xie W, Yang Z (2007) Ba-ZnO catalysts for soybean oil transesterification. Catal Lett 117:159–165

Demirbas A (2009) Production of biodiesel fuels from linseed oil using methanol and ethanol in non-catalytic SCF conditions. Biomass Bioenergy 33:113–118

Encinar JM, Gonzalez JF, Rodriguez-Reinares A (2007) Ethanolysis of used frying oil. Biodiesel preparation and characterization. Fuel Process Technol 88:513–522

Bouaid A, Martinez M, Aracil J (2007) A comparative study of the production of ethyl esters from vegetable oils as a biodiesel fuel optimization by factorial design. Chem Eng J 134:93–99

Lee I, Johnson LA, Hammond EG (1995) Use of branched-chain esters to reduce the crystallization temperature of biodiesel. J Am Oil Chem Soc 72:1155–1160

Christie WW (1989) Gas chromatography and lipids: a pratical guide. Pergamon Press, Oxford, chapter 4

Adolfo Lutz Institute (2008) Métodos físico-químicos para análise de alimentos [Physico-chemical methods for food analysis], 4th edn. Adolfo Lutz Institute, São Paulo, chapter XVI

Cardoso CC, Celante VG, De Castro EVR, Pasa VMD (2014) Comparison of the properties of special biofuels from palm oil and its fractions synthesized with various alcohols. Fuel 135:406–412

Bejan CCC, Celante VG, De Castro EVR, Pasa VMD (2014) Effect of different alcohols and palm kernel (palmist) oils on biofuel properties for special uses. Energy Fuel 28:5128–5135

Fortes ICP, Baugh PJ (1999) Study of analytical on-line pyrolysis of oils from Macauba fruit (Acrocomia sclerocarpa M) via GC/MS. J Braz Chem Soc 10:469–477

Hiane PA, Filho MMR, Ramos MIL, Macedo MLR (2005) Óleo da polpa e amêndoa de bocaiúva acronomia aculeata (jacq.) Iodd. Caracterização e composição em ácidos graxos [Oil of pulp and almond of acrocomia aculeata (jacq.) Iodd. Characterization and composition in fatty acids.]. Braz J Technol 8:256–259

Sahoo PK, Das LM, Babu MKG, Naik SN (2007) Biodiesel development from high acid value polanga seed oil and performance evaluation in a CI engine. Fuel 86:448–454

Navarro-Díaz HJ, Gonzalez SL, Irigaray B, Vieitez I, Jachmanián I, Hense H, Oliveira JV (2014) Macauba oil as an alternative feedstock for biodiesel: characterization and ester conversion by the supercritical method. J Supercrit Fluids 93:130–137

Souza GK, Scheufele FB, Pasa TLB, Arroyo PA, Pereira NC (2016) Synthesis of ethyl esters from crude macauba oil (Acrocomia aculeata) for biodiesel production. Fuel 165:360–366

Fontana JD, Vedana U (2011) Biodiesel para leitores de 9 a 90 anos [Biodiesel for readers from 9 to 90 years old]. UFPR, Curitiba, chapter 9

Dabdoub MJ, Bronzel JL (2009) Biodiesel: Visão crítica do status atual e perspectivas na academia e na indústria [Biodiesel: Critical view of the current status and perspectives in the academy and in industry]. Quim Nov. 32:776–792

Silva NL, Maciel MRW, Batistella CB, Maciel Filho RM (2006) Optimization of biodiesel production from castor oil. Appl Biochem Biotechnol 130:405–414

Gelbard G, Brès O, Vargas RM, Vielfaure F, Schuchardt UF (1995) 1H Nuclear magnetic resonance determination of yield of the transesterification of rapeseed oil with methanol. JAOCS 72:1239–1241

Ghesti GF, Macedo JL, Resck IS, Dias JA, Dias SCL (2007) FT-Raman spectroscopy quantification of biodiesel in a progressive soybean oil transesterification reaction and its correlation with 1H NMR spectroscopy methods. Energy Fuels 21:2475–2480

Ferrari RA, Filho JAA (2012) Macauba as promising substrate for crude oil and biodiesel production. J Agric Sc Technol B 2:1119–1126

Lang X, Dalai AK, Bakhshi NN, Reaney MJ, Hertz PB (2001) Preparation and characterization of bio-diesels from various bio-oils. Bioresour Technol 80:53–62

Aboul-Gheit AK, Abd-el-Moghny T, Al-Eseimi MM (1997) Characterization of oils by differential scanning calorimetry. Thermochim Acta 306:127–130

Claudy P, Letoffé JM, Neff B, Damin B (1986) Diesel fuels: determination of onset crystallization temperature, pour point and filter plugging point by differential scanning calorimetry. Correlation with standard test methods. Fuel 65:861–864

Pérez A, Casas A, Fernández CM, Ramos MJ, Rodríguez L (2010) Winterization of peanut biodiesel to improve the cold flow properties. Bioresour Technol 101:7375–7381

Refaat AA (2009) Correlation between the chemical structure of biodiesel and its physical properties. Int J Environ Sci Technol 6:677–694

Knothe G (2007) Some aspects of biodiesel oxidative stability. Fuel Process Tech 88:669–677

Acknowledgments

The authors appreciate the financial support of Agência Nacional do Petróleo, Gás Natural e Biocombustíveis (ANP), the Financiadora de Estudos e Projetos (FINEP) and the Ministério da Ciência e Tecnologia (MCT) through the Programa de Formação de Recursos Humanos da ANP for the Setor Petróleo e Gás (PRH-ANP/MCT).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silva, L.N., Cardoso, C.C. & Pasa, V.M.D. Production of Cold-Flow Quality Biodiesel from High-Acidity On-Edible Oils—Esterification and Transesterification of Macauba (Acrocomia aculeata) Oil Using Various Alcohols. Bioenerg. Res. 9, 864–873 (2016). https://doi.org/10.1007/s12155-016-9740-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-016-9740-4