Abstract

Dedicated energy crops and crop residues will meet herbaceous feedstock demands for the new bioeconomy in the Central and Eastern USA. Perennial warm-season grasses and corn stover are well-suited to the eastern half of the USA and provide opportunities for expanding agricultural operations in the region. A suite of warm-season grasses and associated management practices have been developed by researchers from the Agricultural Research Service of the US Department of Agriculture (USDA) and collaborators associated with USDA Regional Biomass Research Centers. Second generation biofuel feedstocks provide an opportunity to increase the production of transportation fuels from recently fixed plant carbon rather than from fossil fuels. Although there is no “one-size-fits-all” bioenergy feedstock, crop residues like corn (Zea mays L.) stover are the most readily available bioenergy feedstocks. However, on marginally productive cropland, perennial grasses provide a feedstock supply while enhancing ecosystem services. Twenty-five years of research has demonstrated that perennial grasses like switchgrass (Panicum virgatum L.) are profitable and environmentally sustainable on marginally productive cropland in the western Corn Belt and Southeastern USA.

Similar content being viewed by others

Introduction

Second generation biofuel feedstocks provide an opportunity to increase the production of transportation fuels from recently fixed plant carbon rather than from fossil fuels. There is no “one-size-fits-all” bioenergy feedstock, but crop residues, herbaceous perennial feedstocks, and sugar crops are logical choices for the Corn Belt and much of the Southeastern USA. Crop residues like corn (Zea mays L.) stover are the most readily available bioenergy feedstocks due to their abundance, availability, and producer familiarity. However, on marginally productive cropland, perennial grasses may provide a reliable feedstock supply while providing enhanced ecosystem services. Mitchell et al. [1] focused on four primary advantages that perennial feedstocks have over annual crops such as corn. First, perennials have less annual establishment input requirements. Second, they require fewer herbicide and fertilizer inputs than corn. Third, perennials produce large quantities of biomass with limited inputs. Fourth, perennial crops have the potential to provide multiple ecosystem services like reduced nutrient runoff, reduced erosion, soil carbon sequestration, and wildlife habitat. However, perennial grasses must be profitable, acceptable, and environmentally sustainable to farmers, biorefineries, and society before large-scale adoption of this biomass source becomes a reality.

This paper presents a scientific review of the benefits and challenges of harvesting crop residues and growing dedicated energy crops in the Corn Belt and Southeastern USA. We recognize that feedstock production within an agroecoregion must have a limited impact on the primary production of agricultural crops while providing adequate and reliable feedstock supplies on an already intensively utilized agricultural landscape. Consequently, providing feedstock options that optimize sustainable yield not only drives the economic feasibility of the feedstock, but also the capacity of the landscape to meet agricultural and societal demands [2].

The Regional Biomass Research Centers (RBRCs) were established in 2010 to condense and optimize existing USDA research efforts on bioenergy. Five RBRCs organize USDA Agricultural Research Service (ARS) and Forest Service (FS) bioenergy research to promote collaboration and reduce repetition among researchers in all aspects of the bioenergy-production continuum. The Central-East RBRC focuses on the development of perennial grasses and biomass sorghum (Sorghum spp.), along with corn stover management for lignocellulosic biomass. Integrating perennial grass feedstocks into current agricultural systems may help reduce nutrient escape from fields to surface and ground waters, reduce greenhouse gas emissions, reduce erosion, and increase soil carbon sequestration. The Southeastern RBRC focuses on the development of superior performing herbaceous feedstocks like energycane (Saccharum spp.), biomass sorghum (Sorghum spp.), and other subtropical/tropical perennial grasses like napier grass [Cenchrus purpureus (Schumach.) Morrone]. Plant breeders from these regions have identified herbaceous species and specific genetic traits that could be useful for dedicated biomass crop development. Advances in biomass crop breeding and genetics are covered in an accompanying review (Anderson et al., this issue). There is also a need to identify the best strategies to incorporate dedicated biomass crops into existing annual row crop, pasture, agroforestry, and forest-based systems.

Recent Advancements

A recent report estimated that in 2013, bio-based products added $369 billion to the US economy, employed four million workers, and displaced about 1.1 billion liters of petroleum [3]. Previously, the US Billion-Ton Update [4] provided an estimate of a national inventory of primary bioenergy feedstocks. The report relied upon a large body of research conducted by the USDA-ARS and FS as well as from many universities working on biomass resources. This information was used to estimate biomass production capabilities by regions and allocated land-use changes based on net returns using the Policy Analysis System (POLYSYS), to select potential biomass crops that could grow under specified climactic conditions, and to identify a starting point for development of best management practices [4].

Candidate Feedstocks

Numerous feedstocks have been considered for bioenergy, ranging from crop residues to dedicated energy crops. Because yield is the most important characteristic for biomass feedstocks, only a limited number of candidate feedstocks will comprise a majority of the available land. The primary herbaceous feedstocks for the Central-East and Southeastern RBRC are corn stover, switchgrass (Panicum virgatum L.), polycultures of native prairie species, miscanthus (Miscanthus species, primarily giant miscanthus [M. x giganteus Greef et Deu.]), sugarcane and energycane, napier grass, and sorghums. These species likely will dominate most landscapes in the new bioeconomy. Not surprisingly, a majority of the candidate herbaceous feedstocks are warm-season (C4) grasses, primarily due to higher water use efficiency (WUE) and nitrogen use efficiency (NUE) compared to C3 grasses. However, these warm-season species have varying adaptability in the USA. The plant adaptation region map, constructed by overlapping an ecoregional map with the US plant hardiness zone map, shows a great deal of complexity in determining what particular feedstock produces best at which location [5]. Biomass crops ideally will be produced on marginally productive cropland that is not well suited to commercial food, feed, or fiber production. Marginally productive land may include shallow soils, soils subject to seasonal flooding, anthropogenically engineered soils, small fields, non-irrigated land in irrigated regions, contaminated soils, or urban alcoves. The highest potential for producing biomass on marginally productive lands will come from the Midwest and Southeast USA due to high net primary productivity and available water [6]. A brief description of candidate feedstocks follows.

Corn Stover and Other Crop Residues

Arable land in the Midwest supports the majority of US corn and soybean (Glycine max L.) production. In the US Corn Belt, corn stover availability and expected low feedstock costs make it a likely source for cellulosic biofuel. For example, three commercial-scale cellulosic ethanol plants in Iowa and Kansas are being commissioned in 2015 that will use corn stover as the primary feedstock. Corn stover protects arable land against soil and water and wind erosion, nutrient loss, and is a source of soil organic carbon (SOC). Determining harvestable amounts of corn stover without causing negative impacts on the soil resource and subsequent yields has been a primary research objective for agronomists and soil scientists. Corn stover research conducted by the USDA ARS Renewable Energy Assessment Project (REAP; now known as the Resilient Economic Agricultural Practices) in conjunction with the US Department of Energy Sun Grant Regional Feedstock Partnership has made significant advancements by collecting and summarizing 239 site-years of data on 36 research sites utilizing standardized data collection protocols [7]. The REAP objectives were (i) to determine crop residue amounts needed to protect the soil resource, (ii) compare short- and long-term tradeoffs for use of crop biomass as a bioenergy feedstock versus a soil carbon source, and (iii) to provide recommendations and guidelines for sustainable biomass harvests to producers, industry, and government entities. This information provides a guideline for enabling the USA to reach bioenergy and bioproduct production goals from corn stover while sustaining soil health for future use. Outcomes from REAP research have led to stover management guidelines based on minimum grain yield requirements, maximum stover removal rates, stover harvest frequency, crop rotation, tillage practices, and landscape position. Future research will monitor long-term stover management on soil fertility and quality, development of sub-field management practices to optimize stover removal while minimizing environmental impacts, refinements in producer decision support tools, and evaluating amelioration practices (e.g.,. cover crops, manure, biochar) with residue removal.

Crop residue from other grains such as wheat (Triticum aestivum L.), rice (Oryza sativa L.), oat (Avena sativa L.), and sorghum (Sorghum bicolor L.) are available in many areas of the USA but would be much less abundant than corn stover [4]. In Louisiana, up to 24 Mg ha−1 of post-harvest sugarcane (Saccharum officinarum L.) residue is deposited in the field. However, leaf material from growing plants shows that about $100 ha−1 of N, P, and K are removed if residue is removed with the cane crop (P. White, this paper, unpublished data).

Perennial Herbaceous Crops

Perennial grasses like switchgrass, big bluestem (Andropogon gerardii Vitman), and indiangrass (Sorghastrum nutans (L.) Nash) are being developed as alternatives to annual row crops used for bioenergy feedstock production. Perennial energy crop placement on marginally productive or marginally profitable cropland could improve ecosystem services while providing a more diverse farm enterprise system. Switchgrass, big bluestem, and indiangrass are the dominant grass species in tallgrass prairies and are key components in warm-season pastures and conservation programs. During the early 20th century, significant pasture and hayland areas were required for grazing animals to maintain draft power for rural farms and urban transportation. The transition from draft power to the internal combustion engine in US agriculture contributed to the decline in land dedicated to perennial systems. Significant land areas in the Corn Belt have been identified that are marginally productive for annual crop production, but have excellent potential for growing switchgrass and other perennial grasses [8]. Newly developed switchgrass, big bluestem, and indiangrass cultivars have been released for increased cell wall quality and biomass yields as a result of advances in agronomic research which evaluate these species in monoculture and in mixtures for bioenergy production [9]. The Central-East RBRC, in partnership with the USDA National Institute for Food and Agriculture-funded CenUSA Bioenergy program, has evaluated the use of switchgrass, big bluestem, and indiangrass for producing perennial energy crops in an environmentally sustainable manner. Recent findings include (i) identifying that sufficient land exists in the US Corn Belt to support a cellulosic ethanol industry using both corn stover and switchgrass without impacting productive cropland [10], (ii) the potential of perennial bioenergy crops to sequester soil carbon [11], (iii) release of a bioenergy-specific switchgrass cultivar [12], (iv) documenting that switchgrass ethanol yield potential is similar to corn grain and stover ethanol potential on marginally productive cropland [13], and (v) documenting that existing field-scale and watershed-scale model refinements to address spatial and temporal environmental impacts on cropland conversion to perennial energy crops [9, 14]. Further advancements in genomic selection and concurrent cost reductions likely will allow for accelerated rates of genetic gain (i.e., increased biomass production, increased winter hardiness) in perennial grasses [9].

Switchgrass and native polycultures are well adapted to marginally productive cropland. Switchgrass has been identified as the model herbaceous perennial feedstock because it is broadly adapted and has high yield potential on marginal croplands [15]. An assessment of 10 managed farms produced switchgrass yields between 5.2 and 11.1 Mg ha−1 sustainably on marginal cropland in the upper Midwest with 94 % lower greenhouse gas emissions compared to gasoline [16]. Switchgrass has high biomass yields in most production systems receiving at least 600 mm of annual precipitation, east of the 100th Meridian, or anywhere rainfed corn can be grown reliably [17]. Although switchgrass and other native polycultures tolerate low fertility soils, optimizing biomass and maintaining quality stands requires nitrogen (N) fertilizer inputs and proper harvest management [17]. Low input native polycultures have been evaluated in a limited number of sites and species mixes and are expected to reduce life-cycle greenhouse gas emissions and required inputs [18]. These low input native polycultures often have severely limited yields. However, with increased inputs, production can sometimes be comparable to native monocultures. Both systems lack multi-location comparative evaluations against other high-yielding perennial monocultures [17].

Giant miscanthus has been evaluated as a bioenergy feedstock in Europe and the Eastern USA and has shown high-biomass yield potential with minimal fertilizer requirements. Giant miscanthus biomass production has been highest in Illinois (>30 Mg ha−1 year−1), with lower yield potential in the South and Southeastern regions (2.5 to 17 Mg ha−1 year−1) [19–21]. Giant miscanthus is established by planting rhizomes 5–10 cm deep into a prepared seed bed at 14,000 to 17,000 rhizomes ha−1 in 76-cm rows [22]. Harvestable yields are typical at 18–20 months after planting.

In the USA, sugarcane is grown in the subtropical Gulf Coast Region of Southern Florida, Louisiana, Texas, and Hawaii and is used almost exclusively for sugar. Ethanol production from sugarcane is limited by the short viability period of extracted juice for conversion and the limited harvest period in the continental USA of November to February. Alternative feedstocks are needed from March through October to extend the period of operation. A combination of sweet sorghum which is harvested from July to October [23] and sugar beet (Beta vulgaris L.) could meet the demand for supplemental soluble sugars. Sugar beet has a broad area of adaption and has shown promise as a winter crop in the South [24]. Sugar beet cultivars have been tested in the Southern USA as a winter crop that can be harvested in the spring months after sugarcane harvest and before sweet sorghum. Yields were higher when beets were planted in September and October (69–118 Mg ha−1) versus those planted in November and December (42–69 Mg ha−1) [25]. Growing non-traditional sugar crops provides opportunities for producing a readily fermentable substrate to extend the sugar production period in the southern US.

Energycane is sugarcane bred and produced solely for the purpose of using the biomass as a fuel [26]. Energycane (Saccharum spp.) is derived from parent commercial sugarcane lines and wild sugarcane (Saccharum spontaneum L). Energy cane is typically lower in sugar content than commercial sugarcane cultivars but with increased cold tolerance that enables a wider growing region in the Southeastern USA [27]. Production practices are similar for sugarcane and energy cane, which would allow energy cane producers to use existing sugarcane infrastructure. A commercially released energy cane, “Ho 02-113”, produced dry matter yields greater than 29 Mg ha−1 when sampled from August to March in 2011 and 2012 in Houma, Louisiana (P. White, this paper, unpublished data). Ho 02–113 produced >20 Mg ha−1 of DM (fiber + brix) in two field harvested trials in Winnsboro, Louisiana in 2013 and 2014, with very low inputs of fertilizer or herbicides (P. White, this paper, unpublished data). The energy cane site at Winnsboro was defined as marginally productive for the area due to a shallow plow pan and low available nutrients. The broad harvest interval for energy cane is attributed to cold tolerance genes derived from wild sugarcane. Concomitant with increased cold tolerance is an increase in fiber content which contributes to a reduction in insect susceptibility. Breeding efforts with Saccharum and Miscanthus have shown greater cold tolerance in Saccharum x Miscanthus progeny than in current sugarcane lines, with possible northern expansion for bioenergy [28].

Napier grass, a high-yielding tropical bunchgrass, is a viable perennial feedstock for the Southeastern USA [29]. Napier grass harvest strategies would be similar to other perennial grass systems implementing a one harvest per growing season approach to maximize biomass yield and minimize nutrient removal [29]. Both napier grass and energy cane produce more stalks per unit area than sugarcane, contributing to higher biomass in subtropical regions [27, 29]. Results from Georgia [30, 31] and Florida [19] field trials show that napier grass and energy cane yields were significantly higher than switchgrass, giant miscanthus, and giant reed (Arundo donax L). However, moisture and ash content of napier grass and energy cane could pose a problem for conversion facilities [31].

Annual Crops

Some sorghum (Sorghum bicolor (L.) Moench) cultivars can be key dedicated energy crops based on drought tolerance, high N use efficiency, and high yield potential. Sorghum is grown as an annual in the USA, making it a flexible choice for producers in existing crop rotations. Sorghum is classified into three general categories: grain, sweet, and forage. All three are being evaluated and developed as first or second generation bioenergy feedstocks. Grain sorghum is converted to ethanol in existing first generation ethanol plants. Sweet sorghum primarily would produce sugar accumulated in the stalk and the remaining biomass used for power generation or cellulosic biofuel. Fermentable sugars and juice in sweet sorghum would be pressed and fermented similar to sugarcane. Forage sorghum would be grown for cellulosic biomass. Breeding high yielding grain sorghum lines with the brown midrib gene (bmr) mutation has led to high fiber digestibility and low lignin residue that could be used for biofuel production or livestock feed [32]. Three brown midrib mutants (bmr-6; bmr-12; bmr-18) with reduced lignin have been evaluated and shown to improve ethanol yield in forage sorghum from wild-type lines [33]. These genetic advancements would be significant in water limited regions, particularly in areas where there is livestock demand for highly digestible forages, and first generation ethanol plants accept sorghum grain. Tamang et al. [34] reported an optimum N rate of 108 kg ha−1 for two photoperiod sensitive and two sweet cultivars in the Texas Southern High Plains. Haankuku et al. [35] reported an optimal N rate of 100 kg ha−1 in Oklahoma with no supplemental irrigation, but there was no yield response during drought. Rocateli et al. [36] compared yield of three sorghum types (grain, forage, and photoperiod sensitive) to corn on dry land and irrigated sites in conventional and conservation tillage systems. Biomass was 38 % lower across sorghum types in the dry year compared to the wet year. Conservation tillage increased biomass by 11 % during the dry year, but no difference was observed between tillage systems for the wet year [36]. In the Southeast, sweet and photoperiod sensitive sorghums have been examined as potential energy crops due to high biomass production, low N requirements, and drought tolerance relative to corn [34, 36–38]. Sweet sorghum has additional benefits of a typically shorter growing season and production of fermentable sugars, although biomass production is reduced compared to photoperiod sensitive sorghum [34, 38]. In addition to the bmr gene, low amylose or waxy endosperm genes and sweet genes are being incorporated and evaluated in current breeding programs that would improve sorghum as a bioenergy feedstock [39].

Agronomics of Perennial Grass Feedstocks

The goal of perennial grass feedstock planting is to establish the feedstock as rapidly, completely, and inexpensively as possible [17]. There is substantial cost to establishing perennial biomass feedstocks, and the economic viability of the feedstock is impacted by the success of stand establishment in the seeding year, with stand failure costing farmers more than $300 ha−1 [40]. Perennial grass establishment is limited primarily by weed control, weather, and seed quality. For most perennial grass feedstocks, improved establishment techniques including improved minimum till grass drills, optimal seedbed preparation, seeding depth, planting date, and registered herbicides for weed control have resulted in reliable and rapid establishment [17, 41, 42]. Mitchell and Vogel [43] overcame seed quality issues by developing a seed lot establishment test which based switchgrass seeding rates on emerged seedlings per gram of seed with an associated stress test to reduce risk of seeding failure (Fig. 1).

Regionally specific establishment and management guidelines have been developed for most candidate feedstocks [42, 44]. For example, establishment and management practices for switchgrass have been validated at the field scale in multiple environments [16, 45]. A major issue with switchgrass and other perennial grasses is slow establishment [8]. Mitchell et al. [17] evaluated selected herbicides on stand establishment and subsequent yields of adapted upland switchgrass cultivars in Nebraska, South Dakota, and North Dakota as well as lowland ecotypes in Nebraska. Applying quinclorac (3,7-Dichloroquinolinedichloro-8-carboxylicquinolinecarboxylic acid) plus atrazine (1-Chloro-32-chloro-4-ethylamino-56-isopropylamino-2,4,6 s-triazine) resulted in acceptable stands and high yields for all locations and ecotypes. With good management including the use of herbicides, switchgrass can produce yields equivalent to half of full production during the establishment year and can be at full production the year after planting. Unlike switchgrass and other native grasses which are planted as seed, some perennial grasses are established vegetatively. Giant miscanthus is generally established by rhizomes. Napier grass and energy cane are established similar to sugarcane by planting “seed cane” or mature cane stalks horizontally in rows. For energy cane and sugarcane, the lower nodes of the cane stalks emerge first into whole plants. If the lower nodes are freeze killed, the lower nodules can germinate and replace them. For both napier grass and energy cane, spring survivability was maximized by planting seed cane at least 90 days prior to the first freeze, which is normally by mid-September in southern Georgia [46]. Sufficient weed control was obtained by pendimethalin (3,4-dimethylDimethyl-2,6-dinitro-N-pentan-3-ylanilineyl-aniline) and atrazine for improved height and yield of napier grass [47].

Proper fertility and harvest management are critical to maintain quality stands of most perennial grasses. Although perennial grasses like big bluestem and switchgrass will survive on low fertility soils, the addition of N is needed to optimize biomass [48]. Management strategies have been developed from decades of work with switchgrass [8]. In a recent field-scale evaluation of switchgrass on marginally productive sites in New York, Oklahoma, South Dakota, Virginia, and Iowa using locally adapted cultivars had variable results, only 6 of 19 production environments responding positively to N [49]. In a 10-year study in eastern Nebraska, switchgrass fields receiving no N fertilizer and harvested at anthesis had low biomass and were invaded by C3 grasses and big bluestem and switchgrass stands declined [48]. In fields fertilized with 56 kg N ha−1 and harvested once annually after frost, switchgrass stands were excellent, and invading species were limited. Nitrogen rate can be reduced when harvest occurs after a killing frost because switchgrass cycles some N back to roots during autumn [50]. The optimum N fertilizer rate for switchgrass varies by region, but about 10 kg N ha−1 is needed for each megagrams per hectare of expected biomass [48, 51]. For giant miscanthus, the optimum N fertilizer rate is slightly less than that for switchgrass [44]. Fertilizer requirements for switchgrass and giant miscanthus are less than other annual crops due to translocation of nutrients during senescence [52]. However, in Georgia, switchgrass, napier grass, and energy cane yield declined rapidly after the third year with no fertilizer applications [31]. Fertilizer rates of 100 kg N ha−1 and 90 kg ha−1 potassium (K) were insufficient to replace nutrients removed in harvested napier grass, but fertilized yields were significantly higher than non-fertilized treatments [53]. Using regionally available, alternative sources of nutrients like broiler litter can reduce feedstock production costs. Poultry litter and proportional inorganic N fertilizer resulted in similar biomass yields and N and K removal rates, but more phosphorus (P) was extracted by napier grass from soil amended with poultry litter, suggesting that it could be used to remediate high P soils.

Studies throughout the Great Plains, Midwest, and South generally support a single harvest after senescence to promote sustainable and productive perennial feedstock stands [44, 54, 55]. A database of switchgrass studies from 39 field sites in 17 states supports a single harvest for bioenergy [56]. Harvesting after frost allows N and other nutrients to be mobilized into roots for storage during winter and use for new growth the following spring [50]. Harvesting biomass after frost is beneficial for thermochemical conversion and biopower because antagonistic plant nutrients like N and calcium (Ca) are minimized in the biomass [54]. Leaving switchgrass biomass standing in the field over winter and harvesting the following spring leaches nutrients, maintains gasification energy yield, and provides wildlife habitat, but reduces yield by 20 to 40 % compared with harvesting in autumn after frost [57]. For energy cane, delaying harvest into the late winter months of February and March resulted in changes to biomass moisture, fiber composition, and N, but K decreased [58]. Fiber yield was similar across sample dates but brix dropped rapidly from December into later months. Early harvests are recommended for sugarcanes and type I energy canes (lower sucrose content and higher fiber than sugarcane) energy canes to avoid the loss of fermentable sugars, but type II energy canes (marginal sugar content and higher fiber content than sugarcane or type I energy cane) can be harvested later during the winter months with little change in conversion properties.

Field collection of biomass bales after harvest is a significant expense. Bales often need to be aggregated at the edge of the field prior to shipping to processing facilities. Cannayen et al. [59] reported that bale loader capacity, field area, and number of bales handled affected efficiency, but that field shape, swath width, biomass yield, and randomness of bale layout did not affect aggregation logistics. They reported a self-loading bale picker was most efficient, and savings on cumulative distances that directly influence time, fuel, and cost were realized when the number of bales handled was increased, or additional equipment was utilized.

Biomass processing is an important step in the conversion of perennial grasses and corn stover into next generation biofuels. Although perennial grasses and corn stalks have many similarities, small differences in mechanical properties of these crops may have a significant impact on bioprocessing efficiency. Shear stresses were not different for big bluestem, corn stalk, and intermediate wheatgrass [Thinopyrum intermedium (Host) Barkworth and D.R. Dewey] but were 36 to 53 % less than switchgrass [60]. Corn stalk had the greatest tensile stress followed by switchgrass, big bluestem, and intermediate wheatgrass. Herbaceous feedstocks will require additional consideration when designing energy efficient size-reduction systems.

Quantifying feedstock quality is important regardless of the feedstock or conversion platform. Vogel and Jung [61] reported agronomists, breeders, geneticists, and biorefineries would benefit from a rapid, inexpensive, and accurate method for predicting biofuel conversion. Vogel et al. [62] developed a technique for estimating over 20 components for simultaneous saccharification and fermentation (SSF) that met those criteria using near-infrared reflectance spectroscopy (NIRS). In addition to the primary components of cell wall and soluble sugars, an additional 13 complex feedstock traits can be determined including theoretical and actual ethanol yields from hexose fermentation. Using a multi-year switchgrass cultivar evaluation trial, they identified differences among switchgrass strains for all biomass conversion and composition traits based on cell wall and non-cell wall composition. Sarath et al. [63] reported higher ethanol yields were associated with a decrease in lignification of the cortical sclerenchyma. The NIRS Forage and Feed Testing Consortium has transferred these calibration sets and associated standard samples to multiple laboratories. The calibrations are being refined to provide better predictions as well as being expanded to thermochemical processes and is being used to facilitate research to evaluate and develop other perennial grasses into bioenergy crops [9].

Corn Stover Removal

Future demand for corn stover as livestock feed or as biofuel has increased the importance of determining stover removal effects on biomass production, nutrient dynamics, and the soil resource. Partial stover removal can ameliorate potential yield reductions, especially in high production no-till systems, where high stover accumulation can interfere with planting operations, stand establishment, and increase disease incidence [64]. Corn stover removal trials located across the Central and Eastern USA have evaluated corn grain yield trends under various stover removal rates and management practices [7]. In general, corn grain yields were similar or slightly higher when partial stover removal occurs compared with no stover removal [7, 64–67]. A 3 % average corn grain yield increase was found with stover harvest compared with no stover harvest at REAP stover removal sites. Longitude, latitude, yield level, and previous crop effects accounted for little variation on corn yield [7]. Irrigated corn grain yields were 8 to 9 % higher for no-till when corn stover was removed compared with no residue removal, while grain yields were similar under tillage in all stover removal treatments [67]. Stover removal rates for these studies ranged from 2.5 to 12.4 Mg ha−1.

Stover preserves soil health by adding carbon to the soil. Stover also contains a high proportion of nutrients which may be expensive to replace and are essential for soil health. Johnson et al. [68] determined that corn cobs contain a greater proportion of carbon than stalks and leaves, and that stover from the cob to the top of the plant has higher feedstock quality. Mourtzinis et al. [69] showed that harvesting the above-ear corn plant fraction, while leaving the remaining stover in the field for soil erosion protection and soil organic matter maintenance, is a potential option for corn stover harvest in the Southeast. Other research concluded that harvesting the upper half of standing stover with cobs produced the highest quality feedstock and maintained soil productivity as determined by the soil management assessment framework (SMAF) [70, 71]. Total precipitation and average air temperature during the growing season were strongly correlated with stover chemical composition, and the above ear portion of stover was more desirable due to lower lignin and higher cellulose content [72]. However, stover should not be removed if grain yield is less than 11 Mg ha−1 [73]. Nutrient (N, P, and K) removal is proportional to stover removal, and nutrient removal on per unit area is highest for K, followed by N and P [7]. In the short-term, soil N immobilization is expected to be lower with stover removal resulting in lower N fertilizer requirements for the following corn crop. The economically optimal N rate was >12 kg N ha−1 less with stover removal compared with no stover removal under conservation tillage [74]. Stover removal tends to increase early growing season soil temperature resulting in increased crop development rates [66, 74] but also can lead to increased evaporation rates especially under drought conditions resulting in decreased yields [11, 64]. Ongoing, long-term REAP sites are being monitored for grain yield and soil fertility changes from nutrient removal under continuous stover harvests.

Current stover collection technologies are capable of recovering up to 70 % of the stover, but determining stover collection thresholds to maintain SOC and minimize erosion will differ by soil types, baseline SOC levels, cropping systems, tillage practices, and field topography [64, 75]. Stover retention levels to maintain SOC are higher than retention levels needed to control water or wind erosion [76]. On an irrigated clay loam soil in Colorado, corn yields were higher for partial stover removal than no stover removal but SOC stocks declined in the 0 to 30 cm soil depth while no residue removal showed an increase in SOC stocks over time [66]. Soil property response to stover removal is most sensitive to near-surface soil layers [64, 77] but SOC cycling processes below near-surface soil layers can play a role in cumulative SOC storage [11, 67, 78]. Based on REAP stover removal sites, estimated minimum stover retention rates of 6.4 ± 2.2 Mg stover ha−1 year−1 are required to maintain SOC, but residue retention rates should be considered site and management specific [79]. Reduced particulate organic matter stocks, an early indicator of management effects impacts, have been reported on stover removal sites [80] even when SOC stocks have increased over time [64]. A universal, stover harvest amount recommendation is not possible since management, landscape, and soil type influences stover retention requirements at the field level. Based on current research, partial stover removal may occur when grain yields exceed 11 Mg ha−1, conservation tillage is practiced, and on landscapes with minimal potential for wind or water erosion. Amelioration practices (e.g., manure, cover crops) may still be required to maintain SOC stocks depending on region and soil type. The frequency of stover removal will also impact how much stover can be sustainably removed within a growing season. The potential to couple sustainable agricultural residue harvests with dedicated energy crops would improve land-use efficiency and limit biomass constraints for cellulosic biofuel. A multi-feedstock, landscape approach also minimizes economic and environmental risks in meeting feedstock demands for cellulosic ethanol production by providing sufficient feedstock availability while maintaining or improving ecosystem services [67].

System Sustainability and Climate Change Mitigation Potential

Among the primary system, indicators for sustainability and climate change mitigation potential are changes in SOC and direct emissions of greenhouse gases (GHGs) from the soil surface. The GHGs most commonly associated with agronomic activities are carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O). Although agricultural CO2 fluxes can be large, arable soils are not considered major sources of atmospheric CO2. Net changes in system CO2, or net ecosystem exchange (NEE), can be evaluated in the near-term using micrometeorological approaches or inferred over the long-term by taking measurements of soil carbon changes over time [81]. In particular, building soil organic matter and long-term SOC sequestration are key strategies to both mitigate rising atmospheric CO2 concentrations as well as improve soil quality and soil health. Soils in non-flooded row crop and perennial grass production systems are not important CH4 sources so are not discussed here. In contrast, soil N2O emissions resulting from soil and fertility management practices comprise 92 % of N2O emissions from the agricultural sector and 69 % of national N2O emissions annually, representing the largest anthropogenic N2O source in the USA [82]. Because the global warming potential of N2O is nearly 300 times greater than CO2, whether a system is mitigating or exacerbating atmospheric GHG levels depends on the balance between SOC storage and soil N2O emissions. As demand grows for a reliable and environmentally responsible supply of bio-based feedstocks, how management is adapted to meet these demands will determine the sustainability and climate change mitigation potential of bioenergy production systems.

Both direct measurement and modeling approaches have been utilized to quantify and/or predict near- and long-term SOC changes and soil GHG emissions from bioenergy production systems under an array of conventional and conservation management practices across the USA. Through the Energy Independence and Security Act [83], the US Environmental Protection Agency (USEPA) designated the reduction of total system GHG emissions determined by life cycle assessment (LCA) as a major criterion for accepting viable biomass sources for renewable energy. Soil N management and upstream emissions from N fertilizer production together contribute 46 to 68 % of total GHG emissions from biofuel feedstock production systems [84]. Soil N2O emissions usually are estimated instead of measured and input into LCAs as a constant fraction (i.e., emissions factor, EF) of commercial fertilizer rate (EF = 1 %; [85]. While multi-site, multi-year field measurements of soil N2O emissions show substantial variability in EF at the site level, regionally aggregated results are consistent with the 1 % assumption [86]. Recent model simulations further predict that alternative N management practices (i.e., decreasing N rate, reducing application of nitrification inhibitors) could enhance GHG mitigation potential of biofuel production systems [87]. Most LCA studies do not account for SOC changes despite increasing recognition that including SOC changes in LCAs are necessary to accurately estimate system GHG emissions. When SOC changes are incorporated in LCAs for bioenergy production systems, total system GHG emissions have been shown to differ by 154 % depending on whether near-surface (<30 cm) or sub-surface (>30 cm) SOC changes are used [78].

In the Northeast USA, a switchgrass production system was a net sink of 0.39 Mg C ha−1 year−1 averaged over the first 4 years of the stand [88]. In the Central USA, SOC sequestration in switchgrass production systems occurred in a 5-year on-farm study of 10 sites across Nebraska, South Dakota, and North Dakota [45, 89]. In eastern Nebraska, both switchgrass and corn biomass production systems sequestered SOC after nine continuous years in both annual and perennial biofuel systems. Under best management practices in either system, soil C increased by 2 Mg C ha−1 year−1 [11] with near-term net GHG reductions of −29 to −398 g of CO2 MJ ethanol−1 year−1 [90]. Soil carbon storage also has been measured under switchgrass in the Southeast USA, with sequestration rates ranging from 0.17 to 1.7 Mg C ha−1 year−1 [91, 92].

Growing season soil CO2 and CH4 emissions from switchgrass in the Northern Great Plains are not impacted by fertilizer N rates [93, 94], but higher N inputs can increase yield as well as soil N2O emissions [93]. In contrast, correlations between N rate and soil N2O emissions were obscured by annual variability in weather and soils in a multi-year evaluation of corn stover removal across nine sites in Iowa, Indiana, Minnesota, Nebraska, and South Dakota. When results were aggregated regionally, stover removal decreased soil GHG emissions due to reductions in C and N inputs into soils as well as possible microclimatic differences associated with changes in soil cover [86]. Soil N2O emissions modeled by the Daily Century model (DAYCENT) for a subset of these sites were similar to measured rates when N2O emissions were ≤2 kg N2O-N ha−1 year−1, but underestimated fluxes when measured emissions were >3 kg N2O-N ha−1 year−1 [95]. Further, DAYCENT significantly overestimated SOC losses when tillage was used in these corn-based bioenergy systems compared to measured results. Simulations of SOC changes in the soil carbon model, CQESTR, agreed well with measured SOC in both rainfed and irrigated stover removal studies in eastern Nebraska [96].

Agronomic management practices have been linked to changes in soil health, with SOC used as a primary indicator for various soil functions because of its links to numerous soil biological, chemical, and physical properties [97]. For both annual and perennial bioenergy production systems, biomass removal rates as well as recommended companion management practices intended to ameliorate biomass removal effects (i.e., reduced or no-tillage, change in nutrient inputs, cover crop use) are of specific concern for long-term soil health [98].

Use of perennial grasses on landscapes, especially where soils are marginally productive and/or erosion prone, has been shown to enhance SOC storage and nutrient retention (i.e., P), improve soil bulk density, and reduce erosion risk [45, 89, 99]. Although direct plant measurements of switchgrass grown under higher atmospheric CO2 concentrations indicate that switchgrass may be limited in its potential to boost productivity as atmospheric CO2 concentrations increase [100], model simulations of drought-tolerant cultivars predict switchgrass could withdraw between 3 and 19 % less water than conventional crops under future climate change scenarios [101].

Retention of crop residues in annual crop-based bioenergy production systems can enhance SOC sequestration and reduce erosion risks. Therefore, using best management practices in annual systems are critical for ameliorating crop residue removal impacts. At four Central US locations, stover removal resulted in variable soil microbial community responses based on biochemical and genetic profiling techniques. Stover removal decreased, increased, or did not affect the ratio of soil fungi to bacteria, with variability in responses attributed to differences in specific site characteristics (i.e., soils, management history) and climate [102]. Stover removal, however, consistently degraded soil physical quality at all sites, resulting in decreased soil stocks of particulate organic matter, break down of larger soil aggregates, and increased erosion potential [64, 80]. Companion management practices that enhanced system biomass inputs (e.g., increased fertilizer N rates, cover crop use) tended to ameliorate negative soil impacts of stover removal. Using a process-based crop model developed by USDA-ARS in Temple, TX called the Agricultural Land Management Alternatives with Numerical Assessment Criteria (ALMANAC) [103], model simulations with ALMANAC for biomass sorghum predicted that even when SOC levels were maintained under optimal residue and soil management practices (i.e., 75 % removal under no-till), soil physical properties (i.e., bulk density) still experienced degradation [104].

Agronomic use of co-products resulting from bioenergy production processes also contributes to bioenergy production system sustainability, climate change mitigation potential, and soil health. Land application of biochar resulting from the pyrolysis of annual and perennial biomass materials has received increasing attention for its role in increasing system SOC sequestration potential, improving soil fertility and crop yields, and restoring function to degraded soils [105–107]. Land application of lignin co-products from ethanol biorefineries resulted in second generation ethanol production with the lowest GHG footprint and lowest capital cost compared to selling lignin as a coal substitute or burning lignin to produce electricity at the biorefinery [108].

Variability in field measurements and modeling results highlight the importance of using both empirical and modeled emissions rates and SOC changes to inform the selection of sustainable management practices and in conducting LCAs. System responses to management changes are highly specific to regional climate and local variability in weather and site characteristics like soil type and management history. Coordinated multi-site studies such as USDA-ARS’s REAP and greenhouse gas reduction through Agricultural Carbon Enhancement network (GRACEnet) can provide both empirical data as well as soil, weather, and management data required to execute site-specific, regional, and national model simulations. Further, the GRACEnet/REAP data contribution, discovery, and retrieval system provides the capability of running models internally based on associated soils, management, and weather data [109]. The new USDA-ARS Long-Term Agroecosystem Research sites will contribute information as well. Using meta-analyses of multiple published datasets as well as multi-model comparisons of simulation outputs for the same management/climate change scenarios have enhanced and continue to contribute to the capability of RBRCs to predict management change impacts on bioenergy system sustainability and climate change mitigation potential.

Landscape Estimations and Feedstock Production Modeling

Without adequate and reliable feedstock supplies, biofuel or bio-based chemical facilities are not feasible. For sugars, delivery and use must be within 48 h or be condensed for stabilization. Biomass can be stored for a prolonged period of time in bales or in bulk until processed. However, transportation costs to the conversion facility must be minimized. Thus, it is necessary to have a landscape and climate that is sufficient to grow high yielding feedstocks in close proximity to the conversion facility. To minimize interference with current food, feed, and fiber production, fuel crops should be produced on less productive land. The challenge is to optimize biomass while minimizing inputs. Growing feedstocks must emphasize sustainability and consider soil, water, and air quantity and quality as well as the effects on wildlife habitat.

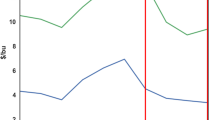

Determining land availability is the key to establishing a bioeconomy. Most US cropland in the Midwest is dedicated to corn and soybeans. As previously mentioned, some corn stover can be recovered for use as a cellulosic feedstock. Uden et al. [10] considered pivot corners (areas outside circular irrigation pivots) and dry land areas of less than 3.7 ha as marginal crop land on which switchgrass could be grown, with about 5 % of the cropland suitable for switchgrass (Fig. 2). They estimated that if switchgrass yield was 5 to 11 Mg ha−1 and if between 30 and 50 % of corn stover was removed, an additional 143 to 251 million L of cellulosic ethanol could be produced and supplement the 208 million L currently being produced from corn. In the southeastern Coastal Plains, cultivated land is in small tracts characterized by irregular shapes and numerous riparian areas. In the Georgia Coastal Plain, Coffin et al. [6] modeled biofuel production zones in marginal buffer areas associated with cropland-riparian edges and grassed waterways. They estimated that 321,000 ha could potentially produce 2.2 to 9.4 Tg of DM from perennial warm-season grasses, providing 778 to 3296 million L of ethanol per year. Such systems, placed advantageously in the landscape, would have the added benefit of removing excess N and other nutrients from agricultural field runoff, which, for N, was estimated at 8100–51,000 Mg per year.

Variability of climate, soils, and agroecosystems in the USA will dictate the regionally appropriate bioenergy feedstock. For example, the Hawaii Clean Energy Initiative (HCEI) sets a goal of 40 % of energy needs coming from local renewable sources [110]. Besides sun, wind, and geothermal sources, biomass from multiple species are being studied for producing renewable energy. Sugarcane has been grown in Hawaii as a sugar crop for over 100 years and is grown in a 2-year irrigation cycle with the bagasse considered a renewable feedstock. The ALMANAC model accurately determined biomass yields (R 2 = 0.77) from crop parameters with different soil types and under different irrigation, N and P applications [111]. The Soil and Water Assessment Tool (SWAT) model was used in Hawaii to simulate water stress and water use in sugarcane [112]. The SWAT model was then used as a decision support tool to provide irrigation managers with comprehensive water balance information.

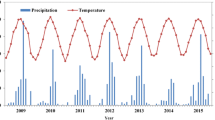

ALMANAC was developed by determining the relationship between biomass yields and different crop growth parameters. ALMANAC uses inputs on light interception responsible for biomass production, soil-water, carbon, and nitrogen dynamics, and the effects of drought [113]. ALMANAC was used to predict yield (3.8 to 20.9 Mg ha−1) and WUE of four switchgrass ecotypes at five sites across the Midwest [113, 114]. Modeled WUE values (3 to 6 mg g−1) tended to match published empirically measured values, with lowland types having the greatest WUE [21, 113]. As changes in climate increases the possibility of drought stress, ecotypes or cultivars with high WUE will be needed to maintain higher yields.

ALMANAC forecasted current and future productivity of switchgrass across the Central and Eastern USA under predicted climate change scenarios. Switchgrass growing in cooler climates flowered earlier had lower WUE and were shorter than from warmer sites [115]. Warmer areas of Florida and the Texas and Louisiana Gulf Coasts have the highest long-term productivity potential. Some of the lower productive agricultural lands in the Northern Great Plains would be expected to experience large increases in productivity with climate change from the model [116]. Yield was predicted to increase in regions with predicted higher temperatures and precipitation. However, climate change in the interior Southeast was not expected to have a large effect on yield.

Managing biomass production will vary greatly across locations and species. Mechanistic models have been used to simulate the effects of irrigation, fertilization, and harvest frequency on switchgrass yields, which can be used to assess multiple management practices to make local planning recommendations [113]. Determining WUE via ALMANAC was achieved by calculating the effects of soil water availability on plant growth from estimates of evaporation, soil water evaporation, and plant water transpiration based on leaf area index. Combining these measurements with variation in soils can help predict which sites are best-suited to switchgrass production rather than corn production [113].

Other Considerations

A major concern for the bioeconomy is competition for resources (i.e., land and water) between bioenergy and traditional crops. This competition is intensified with the additional challenge of feeding an expected world population of 9 billion by the middle of this century [117, 118]. One way to alleviate traditional versus bioenergy crop competition is to grow bioenergy crops during fallow periods that do not conflict with traditional crops. This strategy allows producers to maintain current farming operations while potentially increasing overall net returns with a supplementary bioenergy crop. In the Southeast, this fallow period traditionally corresponds to winter when cover crops are used to protect soil from erosion during high rainfall periods [119]. Biomass produced from a winter cover crop could also be used as an herbaceous biomass source [120].

Winter cereals like rye (Secale cereale L.) are used extensively as cover crops in the Southeast. Ducamp et al. [120] reported rye planted as a cover crop and harvested for bioenergy was more beneficial for cotton (Gossypium hirsutum L.) production than not using a cover crop, but retaining rye residue resulted in the highest seed cotton yields. However, cover crop residue removal as a bioenergy source could be detrimental for a subsequent crop like cotton compared to no cover crop during hot, dry growing seasons [120]. An additional benefit of using a cover crop is that this type of feedstock could enhance the year-round supply needs of a bioenergy facility and reduce feedstock storage requirements.

Incorporating legumes into an annual biomass crop system could reduce N fertilizer requirements, which will reduce bioenergy production inputs [121]. Non-traditional legumes like sunn hemp (Crotolaria juncea L.) could serve directly as a bioenergy crop, particularly in the Southeast. In addition, winter cover crops like vetch (Vicia L.) and lupin (Lupinus L.) may fit well into a biomass sorghum-cotton rotation [122]. As previously mentioned, corn stover is a good bioenergy feedstock that is readily available [123]. In the Southeast, sunn hemp could be planted during the fallow period after corn harvest allowing it to produce significant biomass before frost [124]. Cantrell et al. [125] reported a 204 GJ ha−1 energy yield for sunn hemp biomass collected 3 months after planting. Regression modeling estimated 112 to 151 Tg year−1 of rye biomass could be harvested for bioenergy purposes in continuous corn and corn-soybean rotations in the US Corn Belt [126]. Further, incorporation of winter oilseeds into corn-soybean cropping systems may provide additional farm revenue while providing numerous ecosystem services (e.g., increased biodiversity, soil protection, food source for pollinators) [127].

Another alternative is to rotate traditional and bioenergy annual crops to meet bioenergy feedstock demand [36]. Using annuals in bioenergy feedstock production systems provides farmers with flexibility and does not dedicate fields for 5 to 10 years like perennial production systems. Additionally, annuals such as sorghums, teff, wheat, oat, and triticale offer double-cropping or relay-cropping opportunities with existing crop systems to limit disruption of the current farming operation.

Challenges and Opportunities

Providing a reliable source of high quality feedstocks to the biorefinery in an economically and environmentally sustainable manner that is profitable for the farmer will be the primary challenge for herbaceous feedstocks. Biomass-based systems will require enormous quantities of material. For example, a 300 million L per year plant will require 907,000 DM Mg of feedstock year−1 or 2490 DM Mg of feedstock day−1, requiring 222 ha of feedstock yielding 11.2 DM Mg ha−1 [1]. Significant breeding progress has been made on many of the dedicated energy crops, with yields exceeding 20 DM Mg ha−1 in much of the region. However, capturing the biomass from these high-yielding fields with conventional haying equipment has proven problematic, with 10–40 % of the total standing crop being lost during harvest and transport. Improvements in equipment, harvesting, and transportation strategies for post frost harvests are needed to reduce these losses.

In order to limit competition with the production of food, feed, and fiber, biofuels will likely be grown on land that is marginally productive for crops, which typically are smaller in size, less productive, have poorer soil, and have high erosion potential [128]. Agricultural policies must not penalize farmers for growing bioenergy feedstocks. Research has demonstrated that properly managed switchgrass has a positive carbon balance and a positive energy balance compared to gasoline when grown on land that is marginally productive for annual row crops [16]. Properly managed corn stover can meet these same criteria. More research on the invasive potential for candidate feedstocks throughout the supply chain is needed [129]. But, after significant evaluation and due diligence, fear of the “what if” cannot prevent the deployment of the biofuel industry or of candidate biofuel feedstocks [2]. For example, there was no evidence of switchgrass grown on marginally productive cropland in eastern Nebraska invading adjacent fields or borders after 10 years of management for bioenergy [48].

Energy crop production provides unique opportunities for cultural change, operational diversification, and increasing biodiversity on the agricultural landscape [2]. Current research funding from the USDA-NIFA-CAP grants is rapidly expanding our knowledge of dedicated energy crop production and conversion and has fostered collaborations to accelerate the development of the bioeconomy [9]. Diverse bioenergy cropping systems can provide risk mitigation and economic opportunities for the farmer and environmental benefits such as stabilizing soils and reducing soil erosion, improving water quality, increasing and improving wildlife habitat, and storing C to mitigate greenhouse gas emissions. For energy crops to be adopted by farmers, they must be profitable, fit into existing farming operations, be easy to store, and deliver to the biorefinery, and extension and crop consulting efforts must be provided.

References

Mitchell RB, Vogel KP, Sarath G (2008) Managing and enhancing switchgrass as a bioenergy feedstock. Biofuels Bioprod Biorefin 2:530–539

Mitchell R, Owens V, Gutterson N, Richard E, Barney J (2011) Herbaceous perennials: Placement, benefits and incorporation challenges in diversified landscapes. P. 84–98. In: Sustainable Alternative Fuel Feedstock Opportunities, Challenges and Roadmaps for Six U.S. Regions, R. Braun, D. Karlen, and D. Johnson (eds.). Soil & Water Cons. Soc., Ankeny, IA

Golden JS, Handfield RB, Daystar J, McConnell TE (2015) An economic impact analysis of the U.S. biobased products industry: A report to the congress of the United States of America. A joint publication of the Duke Center for Sustainability & Commerce and the Supply Chain Resource Cooperative at North Carolina State University Available at: http://www.biopreferred.gov/BPResources/files/EconomicReport_6_12_2015.pdf

US Department of Energy (2011) US Billion-Ton Update: biomass supply for a bioenergy and bioproducts industry. RD Perlack B Stokes (Leads), ORNL/TM-2011/224. Oak Ridge National Laboratory, Oak Ridge, p 227

Vogel KP, Schmer MR, Mitchell RB (2005) Plant adaptation regions: ecological and climatic classification of plant materials. Rangeland Ecol Manag 58:315–319

Coffin, A, Strickland T, Anderson W, Lamb M, Lowrance R, Smith C (2015) Potential for production of perennial biofuel feedstocks in conservation buffers on the Coastal Plain of Georgia, USA. BioEnergy Res: 1–14

Karlen DL, Birrell SJ, Johnson JMF, Osborne SL, Schumacher TE, Varvel GE, Ferguson RB, Novak JM, Fredrick JR, Baker JM, Lamb JA, Adler PR, Roth GW, Nafziger ED (2014) Multilocation corn stover harvest effects on crop yields and nutrient removal. Bioenergy Res 7:528–539. doi:10.1007/s12155-013-9390-8

Mitchell R, Vogel KP, Uden DR (2012) The feasibility of switchgrass for biofuel production. Biofuels 3:47–59

Moore KJ, Birrell SJ, Brown RC, Casler MD, Euken JE, Hanna HM, Hayes DJ, Hill JD, Jacobs KL, Kling CL, Laird D, Mitchell RB, Murphy PT, Raman DR, Schwab CV, Shinners KJ, Vogel KP, Volenec JJ (2015) Midwest vision for sustainable fuel production. Bioenergy. doi:10.1080/17597269.2015.1015312

Uden DR, Mitchell RB, Allen CR, Guan Q, McCoy TD (2013) The feasibility of producing adequate feedstock for year-round cellulosic ethanol production in an intensive agricultural fuelshed. BioEnergy Res 6:930–938

Follett RF, Vogel KP, Varvel GE, Mitchell RB, Kimble J (2012) Soil carbon sequestration by switchgrass and no-till maize grown for bioenergy. Bioenergy Res 5:866–875. doi:10.1007/s12155-012-9198-y

Vogel KP, Mitchell RB, Casler M, Sarath G (2014) Registration of Liberty switchgrass. J Plant Regist 8:242–247. doi:10.3198/jpr2013.12.0076crc

Schmer MR, Vogel KP, Varvel GE, Follett RF, Mitchell RB, Jin VL (2014) Energy potential and greenhouse gas emissions from bioenergy cropping systems on marginally productive cropland. PLoS ONE 9, e89501. doi:10.1371/journal.pone.0089501

Porter PA, Mitchell RB, Moore KJ (2015) Reducing hypoxia in the Gulf of Mexico: reimagining a more resilient agricultural landscape in the Mississippi River Watershed. J Soil Water Conserv 70:63–68

Vogel KP (2004) Switchgrass. In: Moser LE, Burson BL, Sollenberger LE (eds) Warm-season (C4) Grasses. ASA-CSSA-SSSA, Madison, pp 561–588

Schmer MR, Vogel KP, Mitchell RB, Perrin RK (2008) Net energy of cellulosic ethanol from switchgrass. Proc Natl Acad Sci UDA 105:464–469

Mitchell R, Vogel KP, Berdahl JD, Masters RA (2010) Herbicides for establishing switchgrass in the Central and Northern Great Plains. BioEnergy Res 3:321–327

Tilman D, Hill J, Lehman C (2006) Carbon-negative biofuels from low-input highdiversity grassland biomass. Science 314:1598-1600

Fedenko JR, Erickson JE, Woodard KR, Sollenberger LE, Venramini JMB, Gilbert RA, Helsel ZR, Peter GF (2013) Biomass production and composition of perennial grasses grown for bioenergy in a subtropical climate across Florida, USA. Bioenergy Res 6:1082–1093

Heaton EA, Dohleman FG, Long SP (2008) Meeting US biofuel goals with less land: the potential of miscanthus. Glob Chang Biol 14:2000–2014

Kiniry JR, Anderson LC, Johnson MV, Behrman KD, Brakie M, Burner DM, Cordsiemon RL, Fay PA, Fritschi FB, Houx JH III, Hawkes C, Juenger T, Kaiser J, Keitt T, Lloyd-Reilley J, Maher S, Raper R, Scott A, Shadow A, West C, Wu Y, Zibilske LM (2013) Perennial biomass grasses and the Mason-Dixon line: comparative productivity across latitudes in the southern Great Plains. BioEnergy Res 6:276–291

Casey A, Kaiser J, Cordsiemon R (2011) Fact sheet for planting and managing giant miscanthus in Missouri for the Biomass Crop Assistance Program (BCAP). USDA-Natural Resources Conservation Service, Plant Materials Center. Elsberry, MO

Shoemaker CE, Bransby DI (2011) The role of sorghum as a bioenergy feedstock In: R. Braun, D.L. Karlen, and D. Johnson (eds.) Sustainable Alternative Fuel Feedstock Opportunities, Challenges and Roadmaps for Six U.S. Regions. Proceedings of the Sustainable Feedstocks for Advanced Biofuel Workshop. Sept. 27–29, 2010. Atlanta, GA. Soil and Water Conservation Society, Ankeny, IA 50023 149–159

Eggleston G, Tew T, Panella L, Klasson T (2010) Ethanol from sugar crops. Industrial Crops and Uses, 60–83

Webster TM, Grey TL, Scully BT, Johnson III WC, Davis RF, Brenneman TB (2015) Yield potential of spring-harvested sugar beet (Beta vulgaris) depends on autumn planting time

Chynoweth DP, Turick CE, Owens JM, Jerger DE, Peck MW (1993) Biochemical methane potential of biomass and waste feedstocks. Biomass Bioenergy 5:95–111

Leon RG, Gilbert RA, Comstock JC (2015) Energycane (Saccharum spp. × Saccharum spontaneum L.) biomass production, reproduction, and weed risk assessment scoring in the humid Tropics and Subtropics. Agron J 107:323–329

Glowacka K, Ahmed A, Sharma S, Abbott T, Comstock JC, Long SP, Sacks EJ (2015) Can chilling tolerance of C4 photosynthesis in Miscanthus be transferred to sugarcane? GCB Bioenergy. doi:10.1111/gcbb.12283

Knoll JE, Johnson JM, Huang P, Lee RD, Anderson WF (2015) Effects of delayed winter harvest on biomass yield and quality of napiergrass and energycane. Biomass Bioenergy 80:330–337. doi:10.1016/j.biombioe.2015.06.018

Bouton J (2002) In Bioenergy Crop Breeding and Production Research in the Southeast, ORNL/SUB-02-19XSV810C/01

Knoll JE, Anderson WF, Strickland TC, Hubbard RK, Malik R (2012) Low-input production of biomass from perennial grasses in the Coastal Plain of Georgia, USA. Bioenergy Res 5:206–214

Yerka MK, Watson A, Toy JJ, Erickson G, Pedersen JF, Mitchell RB (2015) Yield and forage value of a dual-purpose bmr-12 sorghum hybrid. Crop Sci 55:681–687. doi:10.2135/cropsci2014.06.0437

Dien BS, Sarath G, Pedersen JF, Sattler SE, Chen H, Funnell-Harris DL, Nichols NN, Cotta MA (2009) Improved sugar conversion and ethanol yield for forage sorghum (Sorghum bicolor L. Moench) lines with reduced lignin contents. Bioenergy Res 2:153–164

Tamang PL, Bronson KF, Malapati A, Schwartz R, Johnson J, Moore-Kucera J (2011) Nitrogen requirements for ethanol production from sweet and photoperiod sensitive sorghums in the Southern High Plains. Agron J 103:431–440. doi:10.2134/agronj2010.0288

Haankuku C, Epplin FM, Kakani VG (2014) Forage sorghum response to nitrogen fertilization and estimation of production cost. Agron J 106:1659–1666. doi:10.2134/agronj14.0078

Rocateli AC, Raper RL, Balkcom KS, Arriaga FJ, Bransby DI (2012) Biomass sorghum production and compoents under different irrigation/tillage systems for the southeastern U.S. Ind Crops Prod 36:589–598

Hagan AK, Bowen KL, Pegues M, Jones J (2014) Nitrogen rate and variety impact diseases and yield of sorghum for biofuel. Agron J 106:1205–1211. doi:10.2134/agronj13.0483

Han KJ, Alison MW, Pitman WD, Day DF, Kim M, Madsen L (2012) Planting date and harvest maturity impact on biofuel feedstock productivity and quality of sweet sorghum grown under temperate Louisiana conditions. Agron J 104:1618–1624. doi:10.2134/agronj2012.0213

Sarath G, Mitchell RB, Sattler SE, Funnell D, Pedersen JF, Graybosch RA (2008) Opportunities and roadblocks in utilizing forages and small grains for liquid fuels. J Ind Microbiol Biotechnol 35:343–354

Perrin RK, Vogel KP, Schmer MR, Mitchell RB (2008) Farm-scale production cost of switchgrass for biomass. Bioenergy Res 1:91–97

Masters RA, Mitchell R (2007) Weed management. In: Forages: The science of grassland agriculture, 6th Edition, Chap 26: 395–409

Mitchell RB, Vogel KP, Schmer MR (2013) Switchgrass (Panicum virgatum) for biofuel production. Sustainable Ag Energy Community of Practice, eXtension. (http://extension.org/pages/Switchgrass_for_Biofuel_Production)

Mitchell RB, Vogel KP (2012) Germination and emergence tests for predicting switchgrass field establishment. Agron J 104:458–465

Heaton EA, Boersma N, Caveny J, Voigt T, Dohleman F (2014) Miscanthus (Miscanthus x giganteus) for biofuel production. Sustainable Ag Energy Community of Practice, eXtension. (http://www.extension.org/pages/26625/miscanthus-miscanthus-x-giganteus-for-biofuel-production#.VgVA-9JVhBc)

Schmer MR, Liebig MA, Vogel KP, Mitchell RB (2011) Field-scale soil property changes under switchgrass managed for bioenergy. Global Chang Biol-Bioenergy 3:439–448

Knoll JE, Anderson WF (2012) Vegetative propagation of napiergrass and energycane for biomass production in the Southeast United States. Agron J 104:518–522

Cutts GS III, Webster TM, Grey TL, Vencill WK, Lee RD, Tubbs RS, Anderson WF (2011) Herbicide effect on napiergrass (Pennisetum purpureum Schum.) control. Weed Sci 59:255–262

Mitchell RB, Vogel KP (2015) Grass invasion into switchgrass managed for biomass energy. Bioenergy Res. doi:10.1007/s12155-015-9656-4

Hong C, Owens VN, Bransby D, Farris R, Fike J, Heaton E, Kim S, Mayton H, Mitchell R, Viands D (2014) Switchgrass response to nitrogen fertilizer across diverse environments in the USA: a regional feedstock partnership report. Bioenergy Res 7:777–788

Wayman S, Bowden RD, Mitchell RB (2014) Seasonal changes in shoot and root nitrogen distribution in switchgrass (Panicum virgatum). Bioenergy Res 7:243–252

Vogel KP, Brejda JJ, Walters DT, Buxton DR (2002) Switchgrass biomass production in the Midwest USA: harvest and nitrogen management. Agron J 94:413–420

Heaton EA, Dohleman FG, Long SP (2009) Seasonal nitrogen dynamics of Miscanthus x giganteus and Panicum virgatum. GCB Bioenergy 1:297–307

Knoll JE, Anderson WF, Malik R, Hubbard RK, Strickland TM (2013) Production of napiergrass as a bioenergy feedstock under organic versus inorganic fertilization in the Southeast USA. BioEnergy Res 6:974–983

Mitchell RB, Schmer MR (2012) Switchgrass harvest and storage. In: Monti A (ed) Switchgrass, Green Energy and Technology. Springer, London, pp 113–127

Vogel KP, Sarath G, Saathoff A, Mitchell R (2011) Switchgrass. In: Halford N, Karp A (eds) Energy Crops. The Royal Society of Chemistry, Cambridge

Wullschleger SD, Davis EB, Borsuk ME, Gunderson CA, Lynd LR (2010) Biomass production in switchgrass across the United States: database description and determinants of yield. Crop Sci 102:1158–1168

Adler PR, Sanderson MA, Boateng AA, Weimer PJ, Jung H-JG (2006) Biomass yield and biofuel quality of switchgrass harvested in fall or spring. Agron J 98:1518–1525

Knoll JE, Anderson WF, Richard EP, Doran-Peterson J, Baldwin B, Hale AL, Viator RP (2013) Harvest date effects on biomass quality and ethanol yield of new energycane (Saccharum hyb.) genotypes in the Southeast USA. Biomass Bioenergy 56:147–156

Cannayen I, Archer DW, Gustafson C, Schmer MR, Hendrickson JR, Kronberg SL, Keshwani D, Backer L, Hellevang K, Faller T (2014) Biomass round bales infield aggregation logistic scenarios. Biomass Bioenergy 66:12–26

Manlu Y, Cannayen I, Hendrickson J, Sanderson M, Liebig M (2014) Mechanical shear and tensile properties of selected biomass stems. Trans ASABE 57(4):1231–1242 (doi: 10.13031/trans.57.10131)

Vogel KP, Jung HG (2001) Genetic modification of herbaceous plants for feed and fuel. Crit Rev Plant Sci 20:15–49

Vogel KP, Dien B, Jung H, Casler M, Masterson S, Mitchell R (2011) Quantifying actual and theoretical biomass ethanol yields for switchgrass strains using NIRS analyses. Bioenergy Res 4:96–110

Sarath G, Vogel KP, Dien B, Saathoff A, Mitchell R, Chen H (2011) Ethanol yields and cell wall properties in divergently bred switchgrass genotypes. Bioresour Technol 102:9579–9585

Jin VL, Schmer MR, Wienhold BJ, Stewart CE, Varvel GE, Sindelar AJ, Follett RF, Mitchell RB, Vogel KP (2015) Twelve years of stover removal increases soil erosion potential without impacting yield. Soil Sci Soc Am J 79:1169–1178

Adler PR, Rau BM, Roth GW (2015) Sustainability of corn stover harvest strategies in Pennsylvania. Bionergy Res. doi:10.1007/s12155-015-9593-2

Halvorson AD, Stewart CE (2015) Stover removal affects no-till irrigated corn yields, soil carbon, and nitrogen. Agron J 107:1504–1512

Schmer MR, Varvel GE, Follett RF, Jin VL, Wienhold BJ (2014) Tillage and residue management effects on soil carbon and nitrogen under irrigated continuous corn. Soil Sci Soc Am J 78:1987–1996

Johnson JM, Wilhelm WW, Karlen DL, Archer DW, Wienhold BJ, Lightle DT, Laird DA, Baker JM, Ochsner TE, Novak JM, Halvorson AD, Arriaga FJ, Barbour NW (2010) Nutrient removal as a function of corn stover cutting height and cob harvest. BioEnergy Res 3:342–352

Mourtzinis S, Arriaga F, Balkcom KS, Price AJ (2015) Vertical distribution of corn biomass as influenced by cover crop and stover harvest. Agron J 107:232–240. doi:10.2134/agronj14.0166

Karlen DL, Birrell SJ, Hess J (2011) A five-year assessment of corn stover harvest in central Iowa, USA. Soil Tillage Res 115–116:47–55

Cantrell KB, Novak JM, Frederick JR, Karlen DL, Watts DW (2014) Influence of corn residue harvest management on grain, stover, and energy yields. BioEnergy Res 7(2):590–597

Mourtzinis S, Cantrell KB, Arriaga FG, Balkcom KS, Novak JM, Frederick JR, Karlen DL (2014) Distribution of structual carbohydrates in corn plants across the southeastern USA. Bioenergy Res 7:551–558

Karlen DL, Birrell SJ, Wirt AR, Schock N (2013) Corn stover harvest strategy effects on grain yield and soil quality indicators. Agrociencia 17(2):121–140

Sindelar AJ, Coulter JA, Lamb JA, Vetsch JA (2013) Agronomic responses of continuous corn to stover, tillage, and nitrogen management. Agron J 105:1498–1506

Wilhelm WW, Hess J, Karlen D, Johnson JMF, Muth D, Baker J, Gollany H, Novak J, Stott D, Varvel G (2010) Review: balancing limiting factors and economic drivers for sustainable Midwestern US agricultural residue feedstock supplies. Ind Biotechnol 6:271–287

Wilhelm WW, Johnson JMF, Karlen DL, Lightle DT (2007) Corn stover to sustain soil organic carbon further constrains biomass supply. Agron J 99:1665–1667

Blanco-Canqui H, Ferguson RB, Jin VL, Schmer MR, Wienhold BJ, Tatarko J (2014) Can cover crop and manure maintain soil properties after stover removal from irrigated no-till corn? Soil Sci Soc Am J 78:1368–1377. doi:10.2136/sssaj2013.12.0550

Schmer MR, Jin VL, Wienhold BJ (2015) Sub-surface soil carbon changes affects biofuel greenhouse gas emissions. Biomass Bioenergy 81:31–35

Johnson JMF, Novak JM, Varvel GE, Stott DE, Osborne SL, Karlen DL, Lamb JA, Baker J, Adler PA (2014) Crop residue mass needed to maintain soil organic carbon levels: can it be determined? BioEnergy Res 7:481–490. doi:10.1007/s12155-013-9402-8

Osborne SL, Johnson JMF, Jin VL, Hammerbeck AL, Varvel GE, Schumacher TE (2014) The impact of corn residue removal on soil aggregates and particulate organic matter. BioEnergy Res 7:559–567. doi:10.1007/s12155-014-9413-0

Cavigelli MA, Parkin TB (2012) Cropland management contributions to greenhouse gas flux: central and eastern U.S. In: Liebig MA, Franzluebbers AJ, Follett RF (eds) Managing Agricultural Greenhouse Gases: Coordinated Agricultural Research through GRACEnet to Address our Changing Climate. Academic, New York, pp 129–165

USEPA (2011) Inventory of U.S. greenhouse gas emissions and sinks: 1990–2009

Energy Independence and Security Act (Final Rule) 75 Federal Register 14669 (March 26, 2010), pp. 14669–14904

Adler PR, Del Grosso SJ, Inman D, Jenkins RE, Spatari S, Zhang Y (2012) Mitigation opportunities for life cycle greenhouse gas emissions during feedstock production across heterogeneous landscapes. In: Liebig MA, Franzluebbers AJ, Follett RF (eds) Managing Agricultural Greenhouse Gases: Coordinated Agricultural Research through GRACEnet to Address our Changing Climate. Academic, New York, pp 203–219

IPCC (2006) Guidelines for national greenhouse gas inventories, volume 4, Agriculture, forestry and other land use, Intergovernmental Panel on Climate Change

Jin VL, Baker JM, Johnson JM, Karlen DL, Lehman RM, Osborne SL, Sauer TJ, Stott DE, Varvel GE, Venterea RT, Schmer MR, Wienhold BJ (2014) Soil greenhouse gas emissions in response to corn stover removal and tillage management across the US corn belt. BioEnergy Res 7(2):517–527

Ogle SM, McCarl B, Baker J, Del Grosso S, Adler P, Paustian K, Parton W (2015) Managing the nitrogen cycle to reduce greenhouse gas emissions from crop porudction and biofuel expansion. Mitig Adapt Strat Glob Chang. doi:10.1007/s11027-015-9645-0

Skinner RH, Adler PR (2010) Carbon dioxide and water fluxes from switchgrass managed for bioenergy production. Agric Ecosyst Environ 138:257–264

Liebig MA, Schmer MR, Vogel KP, Mitchell RB (2008) Soil carbon storage by switchgrass grown for bioenergy. BioEnergy Res 1:215–222

Schmer MR, Vogel KP, Varvel GE, Follett RF, Mitchell RB, Jin VL (2014) Energy potential and greenhouse gas emissions from bioenergy cropping systems on marginally productive cropland. PLoS ONE 9(3), e89501. doi:10.1371/journal.pone.0089501

Garten CT, Wullschleger SD (2000) Soil carbon dynamics beneath switchgrass as indicated by stable isotope analysis. J Environ Qual 29:645–653

McLaughlin SB, De La Torre Ugarte DG et al (2002) High-value renewable energy from prairie grasses. Environ Sci Technol 36:2122–2129

Schmer MR, Liebig MA, Hendrickson JR, Tanaka DL, Phillips RL (2012) Growing season greenhouse gas flux from switchgrass in the northern Great Plains. Biomass Bioenergy 45:315–319

Mbonimpa EG, Hong CO, Owens VN, Lehman RM, Osborne SL, Schumacher TE, Clay DE, Kumar S (2015) Nitrogen fertilizer and landscape position impacts on CO2 and CH4 fluxes from a landscape seeded to switchgrass. Glob Chang Biol-Bioenergy 7:836–849

Campbell EE, Johnson JMF, Jin FL, Lehman RM, Osborne SL, Varvel GE, Paustian K (2014) Assessing the soil carbon, biomass production, and nitrous oxide emission impact of corn stover management for bioenergy feedstock production using DAYCENT. BioEnergy Res 7:491–502

Wienhold BJ, Schmer MR, Jin VL, Varvel GE, Gollany H (2015) CQESTR simulated changes in soil organic carbon under residue management practices in continuous corn systems. BioEnergy Res. doi:10.1007/s12155-015-9654-6

Lehman RM, Cambardella CA, Stott DE, Acosta-Martínez V, Manter DK, Buyer JS, Maul JE, Smith JL, Collins HP, Halvorson JJ, Kremer RJ, Lundgren JG, Ducey TF, Jin VL, Karlen DL (2015) Understanding and enhancing soil biological health: the solution for reversing soil degradation. Sustain 7:988–1027

Johnson JMF, Novak JM (2012) Sustainable bioenergy feedstock production systems: integrating carbon dynamics, erosion, water quality, and greenhouse gas production. In: Liebig MA, Franzluebbers AJ, Follett RF (eds) Managing Agricultural Greenhouse Gases: Coordinated Agricultural Research through GRACEnet to Address our Changing Climate. Academic, New York, pp 111–126

Stewart CE, Follett RF, Pruessner EG, Varvel GE, Vogel KP, Mitchell RB (2015) Nitrogen and harvest effects on soil properties under rainfed switchgrass and no-till corn over 9 years: implications for soil quality. GCB Bioenergy 7:288–301

Fay PA, Polley HW, Jin VL, Aspinwall MJ (2012) Productivity of well-watered Panicum virgatum does not increase with CO2 enrichment. J Plant Ecol 5(4):366–375

Uden DR, Allen CR, Mitchell RB, Guan Q, McCoy TD (2013) Bioenergy feedstock development scenarios & potential impacts on regional groundwater withdrawals. J Soil Water Conserv 68:124–128

Lehman RM, Ducey TF, Jin VL, Acosta-Martínez V, Ahlschwede CM, Jeske ES, Drijber RA, Cantrell KB, Frederick JR, Fink DM, Osborne SL, Novak JM, Johnson JMF, Varvel GE (2014) Soil microbial community response to corn stover harvesting under rain-fed, no-till conditions at multiple US locations. BioEnergy Res 7:540–550

Kiniry JR, Williams JR, Gassman PB, Debaeke P (1992) A general process oriented model for two competing plant species. Trans ASABE 35:801–810