Abstract

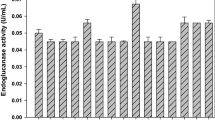

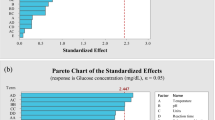

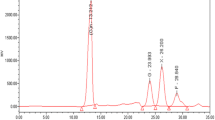

The conversion of agro-industrial residues, such as sugarcane bagasse, into high-value products and renewable energy, within the biorefinery concept, is a potential alternative towards the sustainable management of these resources. This work evaluates the production of cellulolytic enzymes by a selected strain of Aspergillus niger cultivated in sugarcane bagasse under solid-state fermentation using an instrumented lab-scale bioreactor. The effects of environmental factors including the type of substrate and medium composition, as well as the operational conditions (air flow rate, inlet air relative humidity, and initial substrate moisture content) on the production of the enzymatic complex were evaluated using statistical design tools. Significant increases in FPase, endoglucanase, and xylanase activities were achieved under the optimized conditions predicted by the models, with values of 0.88, 21.77, and 143.85 IU/g of dry solid substrate, respectively, representing around ten-, four-, and twofold increases compared to the activities obtained under the initial growth conditions. This demonstrates the importance of evaluating environmental and operational criteria in order to achieve efficient enzyme production. The crude enzymatic extract obtained under optimized conditions was employed for enzymatic hydrolysis of pretreated sugarcane bagasse. Approximately 13 % of total reducing sugars, and a glucose concentration of 2.54 g/L, were obtained after 22 h of hydrolysis of steam exploded sugarcane bagasse, indicating that the enzymatic cocktail produced has good potential for use in the conversion of biomass.

Similar content being viewed by others

References

Sun J, Sun X, Zhao H, Sun R (2004) Isolation and characterization of cellulose from sugarcane bagasse. Polym Degrad Stab 84:331–339

Lynd L, Weimer P, van Zyl W, Pretorius I (2002) Microbial cellulose utilization: fundamentals and biotechnology. Microbiol Mol Biol Rev 66:506–577

Kamm B, Kamm M (2004) Principles of biorefineries. Appl Microbiol Biot 64:137–145

Dodd D, Cann I (2009) Enzymatic deconstruction of xylan for biofuel production. GC B Bioenergy 1:2–17

Wilson D (2009) Evidence for a novel mechanism of microbial cellulose degradation. Cellulose 16:723–727

Merino S, Cherry J, Olsson L (2007) Progress and challenges in enzyme development for biomass utilization. Biofuels 108:95–120

Singhania R, Sukumaran R, Patel A, Larroche C, Pandey A (2010) Advancement and comparative profiles in the production technologies using solid-state and submerged fermentation for microbial cellulases. Enzyme Microb Technol 46:541–549

Holker U, Lenz J (2005) Solid-state fermentation—are there any biotechnological advantages? Curr Opin Microbiol 8:301–306

Farinas C, Vitcosque G, Fonseca R, Bertucci Neto V, Couri S (2011) Modeling the effects of solid state fermentation operating conditions on endoglucanase production using an instrumented bioreactor. Ind Crop Prod 34:1186–1192

Rahardjo Y, Tramper J, Rinzema A (2006) Modeling conversion and transport phenomena in solid-state fermentation: a review and perspectives. Biotechnol Adv 24:161–179

Pandey A, Soccol C (2000) Economic utilization of crop residues for value addition: a futuristic approach. J Sci Ind Res India 59:12–22

Heck J, Flores S, Hertz P, Ayub M (2006) Statistical optimization of thermo-tolerant xylanase activity from Amazon isolated Bacillus circulans on solid-state cultivation. Bioresource Technol 97:1902–1906

Couri S, deFarias A (1995) Genetic manipulation of Aspergillus niger for increased synthesis of pectinolytic enzymes. Rev Microbiol 26:314–317

Pelczar M, Chan E, Krieg N (1990) Microbiology. Tata Mcgraw-Hill, New Delhi

Rodriguez-Zuniga U, Farinas C, Bertucci-Neto V, Couri S, Crestana S (2011) Aspergillus niger production of cellulases by solid-state fermentation. Pesqui Agropecu Bras 46:912–919

Mandels M, Weber J (1969) Production of cellulases. Adv Chem Ser 1969:391–413

do Gouveia E, Nascimento R, Souto-Maior A, Rocha G (2009) Validation of methodology for the chemical characterization of sugar cane bagasse. Quim Nova 32:1500–1503

Miller G (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Ghose T (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268

Bailey M, Poutanen K (1989) Production of xylanolytic enzymes by strains of Aspergillus. Appl Microbiol Biot 30:5–10

Couri S, Terzi S, Pinto G, Freitas S, da Costa A (2000) Hydrolytic enzyme production in solid-state fermentation by Aspergillus niger 3T5B8. Process Biochem 36:255–261

Ahamed A, Singh A, Ward O (2005) Culture-based strategies for reduction of protease activity in filtrates from Aspergillus niger NRRL-3. World J Microb Biot 21:1577–1583

Ahamed A, Vermette P (2008) Culture-based strategies to enhance cellulase enzyme production from Trichoderma reesei RUT-C30 in bioreactor culture conditions. Biochem Eng J 40:399–407

Camassola M, Dillon A (2010) Cellulases and xylanases production by penicillium echinulatum grown on sugar cane bagasse in solid-state fermentation. Appl Biochem Biotech 162:1889–1900

Brijwani K, Oberoi H, Vadlani P (2010) Production of a cellulolytic enzyme system in mixed-culture solid-state fermentation of soybean hulls supplemented with wheat bran. Process Biochem 45:120–128

Chapman B, Winley E, Fong A, Hocking A, Stewart C, Buckle K (2007) Ascospore inactivation and germination by high pressure processing is affected by ascospore age. Innov Food Sci Emerg 8:531–534

Jorgensen H, Olsson L (2006) Production of cellulases by Penicillium brasilianum IBT 20888—effect of substrate on hydrolytic performance. Enzyme Microb Tech 38:381–390

Sorensen A, Teller P, Lubeck P, Ahring B (2011) Onsite enzyme production during bioethanol production from biomass: screening for suitable fungal strains. App Biochem Biotech 164:1058–1070

Raghavarao K, Ranganathan T, Karanth N (2003) Some engineering aspects of solid-state fermentation. Biochem Eng J 13:127–135

Dominguez A, Rivela I, Couto S, Sanroman M (2001) Design of a new rotating drum bioreactor for ligninolytic enzyme production by Phanerochaete chrysosporium grown on an inert support. Process Biochem 37:549–554

Latifian M, Hamidi-Esfahani Z, Barzegar M (2007) Evaluation of culture conditions for cellulase production by two Trichoderma reesei mutants under solid-state fermentation conditions. Bioresource Technol 98:3634–3637

Deschamps F, Giuliano C, Asther M, Huet M, Roussos S (1985) Cellulase production by Trichoderma harzianum in static and mixed solid-state fermentation reactors under nonaseptic conditions. Biotechnol Bioeng 27:1385–1388

Rocky-Salimi K, Hamidi-Esfahani Z (2010) Evaluation of the effect of particle size, aeration rate and harvest time on the production of cellulase by Trichoderma reesei QM9414 using response surface methodology. Food Bioprod Process 88:61–66

Minjares-Carranco A, Trejo-Aguilar BA, Aguilar G, Viniegra-González G (1997) Physiological comparison between pectinase-producing mutants of Aspergillus niger adapted either to solid-state fermentation or submerged fermentation. Enzyme Microb Tech 21:25–31

Viniegra-González G, Favela-Torres E, Aguilar CN, Rómero-Gomez SJ, Díaz-Godínez G, Augur C (2003) Advantages of fungal enzyme production in solid state over liquid fermentation systems. Biochem Eng J 13:157–167

Gao DH, Uppugundla N, Chundawat SPS, Yu XR, Hermanson S, Gowda K, Brumm P, Mead D, Balan V, Dale BE (2011) Hemicellulases and auxiliary enzymes for improved conversion of lignocellulosic biomass to monosaccharides. Biotechnol Biofuels 4:1–11

Sukumaran R, Singhania R, Mathew G, Pandey A (2009) Cellulase production using biomass feed stock and its application in lignocellulose saccharification for bio-ethanol production. Renew Energ 34:421–424

Gottschalk L, Oliveira R, Bon E (2010) Cellulases, xylanases, beta-glucosidase and ferulic acid esterase produced by Trichoderma and Aspergillus act synergistically in the hydrolysis of sugarcane bagasse. Biochem Eng J 51:72–78

Acknowledgments

The authors would like to thank Embrapa, CNPq, and Finep (all from Brazil) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rodríguez-Zúñiga, U.F., Couri, S., Neto, V.B. et al. Integrated Strategies to Enhance Cellulolytic Enzyme Production Using an Instrumented Bioreactor for Solid-State Fermentation of Sugarcane Bagasse. Bioenerg. Res. 6, 142–152 (2013). https://doi.org/10.1007/s12155-012-9242-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-012-9242-y