Abstract

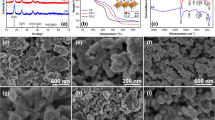

The dense thin membrane for oxygen separation was manufactured from Ba0.5Sr0.5Co0.8Fe0.2O3−δ (BSCF) mixed oxide with perovskite-like structure prepared by the solid-state method. Properties of both powder and granulate (chemical and phase compositions, the specific surface area and the porosity) as well as sintered material (the apparent density, the apparent porosity, the water absorbability, the chemical composition, the crystallographic structure and microstructure), that affect the process of ion oxygen permeation through membrane, were determined. Parameters influencing on usable properties of membranes viz., the bending strength and the coefficient of thermal expansion were assessed as well. Effect of the sintering temperature on membrane structure was evaluated. The elaborated fabrication procedure enables one to manufacture membrane, in which microstructure is characterized by the presence of big grains as well as decreased concentration of grain boundaries. Measurements of the oxygen permeation through BSCF membrane revealed that the highest oxygen flux reaching 2.6 cm3 O2/(cm2 min) was obtained at 950°C under air and helium flows equal to 1 dm3 min−1.

Similar content being viewed by others

References

Lu H, Cong Y and Yang W S 2006 Solid State Ionics 177 595

Tan L, Gu X, Yang L, Jin W, Zhang L and Xu N 2003 J. Membr. Sci. 212 157

Sunarso J, Baumann S, Serra J M, Meulenberg W A, Liu S, Lin Y S and Diniz da Costa J C 2008 J. Membr. Sci. 320 13

Wang H, Tablet C, Feldhoff A and Carlo J 2005 J. Membr. Sci. 262 20

Gromada M, Świder J, Trawczyński J, Stępień M and Wierzbicki M 2012 Ceram. Mater. 64 42 (in Polish)

Zeng P, Ran R, Chen Z, Gu H, Shao Z, Diniz da Costa J C and Liu S 2007 J. Membr. Sci. 302 171

Shiguang L, Wanqin J, Nanpinx X and Jun S 1999 Solid State Ionics 124 161

Bayaktar D, Clemens F, Diethelm S, Graule T, Herle J V and Holtappels P 2007 J. Eur. Ceram. Soc. 27 2455

Acknowledgements

This scientific work was supported by the National Centre for Research and Development, within the confines of Research and Development Strategic Program ‘Advanced Technologies for Energy Generation’ project no. 2 ‘Oxy-combustion technology for PC and FBC boilers with CO 2 capture’, Agreement no. SP/E/2/66420/10. The support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

GROMADA, M., ŚWIDER, J., TRAWCZYŃSKI, J. et al. Oxygen separating membrane manufactured from Ba0.5Sr0.5Co0.8Fe0.2O3−δ perovskite-like material. Bull Mater Sci 38, 23–28 (2015). https://doi.org/10.1007/s12034-014-0809-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-014-0809-4