Abstract

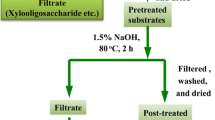

Levulinic acid production, directly from lignocellulosic biomass, resulted in low yields due to the poor substrate accessibility and occurrence of side reactions. The effects of reaction conditions, enzymatic pretreatment, and inhibitor addition on the conversion of steam-exploded rice straw (SERS) short fiber to levulinic acid catalyzed by solid superacid were investigated systematically. The results indicated that the optimal reaction conditions were temperature, time, and solid superacid concentration combinations of 200 °C, 15 min, and 7.5 %. Enzymatic pretreatment improved the substrate accessibility to solid superacid catalyst, and p-hydroxyanisole inhibitor reduced the side reactions during reaction processes, which helped to increase levulinic acid yield. The levulinic acid yield reached 25.2 % under the optimal conditions, which was 61.5 % higher than that without enzymatic pretreatment and inhibitor addition. Therefore, enzymatic pretreatment coupled with the addition of p-hydroxyanisole increased levulinic acid production effectively, which contributed to the value-added utilization of lignocellulosic biomass.

Similar content being viewed by others

References

Chen, H. Z., & Li, G. H. (2013). An industrial level system with nonisothermal simultaneous solid state saccharification, fermentation and separation for ethanol production. Biochemical Engineering Journal, 74, 121–126.

Rackemann, D. W., & Doherty, W. O. S. (2011). The conversion of lignocellulosics to levulinic acid. Biofpr, 5, 198–214.

Menon, V., & Rao, M. (2012). Trends in bioconversion of lignocellulose: biofuels, platform chemicals & biorefinery concept. Progress in Energy and Combustion Science, 38, 522–550.

Wang, N., & Chen, H. Z. (2013). Manufacture of dissolving pulps from cornstalk by novel method coupling steam explosion and mechanical carding fractionation. Bioresource Technology, 139, 59–65.

Troy, R., & Zhang, C. H. (2012). Two-stage acid-catalyzed conversion of carbohydrates into levulinic acid. Industrial and Engineering Chemistry Research, 51, 3265–3270.

Weingarten, R., Jr Conner, W. C., & Huber, G. W. (2012). Production of levulinic acid from cellulose by hydrothermal decomposition combined with aqueous phase dehydration with a solid acid catalyst. Energy and Environmental Science, 5, 7559–7574.

Vishnu, M., & Rao, M. (2012). Trends in bioconversion of lignocellulose: biofuels, platform chemicals & biorefinery concept. Progress in Energy and Combustion, 38, 522–550.

Yan, L., Yang, N., Pang, H., & Liao, B. (2008). Production of levulinic acid from bagasse and paddy straw by liquefaction in the presence of hydrochloride acid. Clean-Soil, Air, Water, 36, 158–163.

Yang, Z. G., Kang, H. Y., Guo, Y. F., Zhuang, G. Q., Bai, Z. H., Zhang, H. X., Feng, C. X., & Dong, Y. P. (2009). Dilute-acid conversion of cotton straw to sugars and levulinic acid via 2-stage hydrolysis. Industrial Crops and Products, 46, 205–209.

Mizuho, Y., Hirokazu, K., & Atsushi, F. (2014). Catalytic transformation of cellulose into platform chemicals. Applied Catalysis B Environmental, 145, 1–9.

Chen, H. Z., Yu, B., & Jin, S. Y. (2011). Production of levulinic acid from steam exploded rice straw via solid superacid S2O8 2−/ZrO2–SiO2–Sm2O3. Bioresource Technology, 102, 3568–3570.

Girisuta, B., Janssen, L., & Heeres, H. (2007). Kinetic study on the acid-catalyzed hydrolysis of cellulose to levulinic acid. Industrial and Engineering Chemistry Research, 46, 1696–1708.

Zhao, Z. M., Wang, L., & Chen, H. Z. (2016). Physical structure changes of solid medium by steam explosion sterilization. Bioresource Technology, 203, 204–210.

Van Soest, P. J., Robertson, J. B., & Lewis, B. A. (1991). Methods for dietary fiber, neutral detergent fiber, and non-starch polysaccharides in relation to animal nutrition. Journal of Dairy Science, 74, 3583–3597.

Wu, Y. N., Guo, H. F., Cui, X. L., & Yan, P. (2008). Study on the superacid catalyst S2O8 2−/ZrO2–SiO2–Sm2O3: characterization of structure. Chemical Research and Application, 20, 1468–1471.

Liu, K., Fang, G., Ma, Y., & Zhao, Y. (2007). Study on preparation of levulinic acid by acid hydrolysis of rice straw. Biochemical and Chemical Engineering, 41, 13–16.

Fang, Q., & Hanna, M. A. (2002). Experimental studies for levulinic acid production from whole kernel grain sorghum. Bioresource Technology, 81, 187–192.

Asghari, F. S., & Yoshida, H. (2006). Acid-catalyzed production of 5-hydroxymethyl furfural from D-fructose in subcritical water. Industrial and Engineering Chemistry Research, 45, 2163–2173.

Sohn, J. R., Lee, S. H., & Lim, J. S. (2006). New solid superacid catalyst prepared by doping ZrO2 with Ce and modifying with sulfate and its catalytic activity for acid catalysis. Catalysis Today, 116, 143–150.

Koutinas, A. A., Wang, R. H., & Webb, C. (2007). The biochemurgist–bioconversion of agricultural raw materials for chemical production. Biofpr, 1, 24–38.

Sohn, J. R. (2004). Recent advances in solid superacids. Journal of Industrial and Engineering Chemistry, 10, 1–15.

Peters, T. A., Benes, N. E., Holmen, A., & Keurentjes, J. T. F. (2006). Comparison of commercial solid acid catalysts for the esterification of acetic acid with butanol. Applied Catalysis A: General, 297, 182–188.

Chen, F., Meng, X., & Xiao, F. S. (2011). Mesoporous solid acid catalysts. Catalysis Surveys from Asia, 15, 37–48.

Manzer, L. E. (2006). Biomass derivatives: a sustainable source of chemicals. ACS Symposium Series, 9, 21–25.

Minsu, K., Seung, W. K., Jin-Woo, K., Tae, H. K., & Jun, S. K. (2013). Optimization of levulinic acid production from Gelidium amansii. Renewable Energy, 54, 173–179.

Daiane, B. B., Magale, K. D. R., Tiele, M. R., André, L. C., & Ayrton, F. M. (2013). Cleaner production: levulinic acid from rice husks. Journal of Cleaner Production, 47, 96–101.

Acknowledgments

This work was financially supported by the National High Technology Research and Development Program (863 Program, 2012AA021302) and the Open Funding Project of the State Key Laboratory of Biochemical Engineering (No. 2013KF-01).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, LT., Zhao, ZM., Yu, B. et al. Enzymatic Pretreatment Coupled with the Addition of p-Hydroxyanisole Increased Levulinic Acid Production from Steam-Exploded Rice Straw Short Fiber. Appl Biochem Biotechnol 180, 945–953 (2016). https://doi.org/10.1007/s12010-016-2144-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-016-2144-2