Abstract

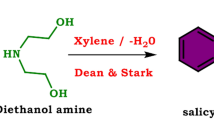

Eight eco-friendly protective coatings (PU, PUA1, PUA3, PUA5, T30PUA5, T60PUA5, T90PUA5, and T120PUA5), were formulated based on series of laboratory-synthesized poly(urethane co-sulfone amide) copolymer dispersions (CPDs) as binders. The first four formulations were based on CPDs prepared by the copolymerization reaction of PU based on castor oil (CO) with aromatic polyamide sulfone (APAS) in four different concentrations (0%, 1%, 3%, and 5% solid to solid). The other four formulations were based on CPDs synthesized by the copolymerization reaction of PU based on transesterified CO with triethanolamine (CON) at different time intervals (30, 60, 90, and 120 min) with APAS at only one concentration. The effect of the degree of copolymerization and transesterification reactions on the physical, chemical, and mechanical properties of the formulated coatings was studied. The results showed that the copolymerization and transesterification reactions led to an increase in the density and viscosity of the coating formulations. Additionally, the hardness of the dried films increased with copolymerization and transesterification reactions. The transesterification reaction decreased the adhesion force of the coated films. The copolymerization process caused a decrease in the water uptake of the coated films. However, the transesterification reaction increased the water uptake. The prepared formulations were applied on carbon steel substrates to estimate their efficiency as eco-friendly protective coatings for steel. The weight loss of the coated steel panels decreased with an increase in the amount of the copolymerized APAS within the PU chains, while it increased with an increase in the transesterification time of the CON used in the preparation of the coated copolymers. From the corrosion test results, PUA5 and T30PUA5 showed the best anticorrosive performance as estimated from the degree of rusting, weight loss measurements, and failure at scribe.

Similar content being viewed by others

References

Buchheit, RG, “Corrosion Resistant Coatings and Paints.” In: Handbook of Environmental Degradation of Materials, 2nd ed. Elsevier Inc. (2012)

Heidarian, M, Shishesaz, MR, Kassiriha, SM, Nematollahi, M, “Characterization of Structure and Corrosion Resistivity of Polyurethane/Organoclay Nanocomposite Coatings Prepared Through an Ultrasonication Assisted Process.” Prog. Org. Coat., 68 180–188 (2010)

Akbarinezhad, E, Bahremandi, M, Faridi, HR, Rezaei, F, “Another Approach for Ranking and Evaluating Organic Paint Coatings Via Electrochemical Impedance Spectroscopy.” Corros. Sci., 51 356–363 (2009)

Papaj, EA, Mills, DJ, Jamali, SS, “Effect of Hardener Variation on Protective Properties of Polyurethane Coating.” Prog. Org. Coat., 77 2086–2090 (2014)

Revie, RW, Uhlig, HH, “Corrosion and Corrosion Control.” In: An Introduction to Corrosion Science and Engineering, 4th ed. John Wiley and Sons, New York (2008)

Patel, CJ, Mannari, V, “Air-Drying Bio-Based Polyurethane Dispersion from Cardanol: Synthesis and Characterization of Coatings.” Prog. Org. Coat., 77 997–1006 (2014)

Ramezanzadeh, B, Ghasemi, E, Mahdavian, M, Changizi, E, Moghadam, MHM, “Effect of Hardener Variation on Protective Properties of Polyurethane Coating.” Carbon, 93 555–573 (2015)

Akbarian, M, Olya, ME, Mahdavian, M, Ataeefard, M, “Effects of Nanoparticulate Silver on the Corrosion Protection Performance of Polyurethane Coatings on Mild Steel in Sodium Chloride Solution.” Prog. Org. Coat., 77 1233–1240 (2014)

Mills, DJ, Jamali, SS, Paprocka, K, “Investigation into the Effect of Nano-Silica on the Protective Properties of Polyurethane Coatings.” Surf. Coat. Technol., 209 137–142 (2012)

Gurunathan, T, Rao, CRK, Narayan, R, Raju, KVSN, “Synthesis, Characterization and Corrosion Evaluation on New Cationomeric Polyurethane Water Dispersions and Their Polyaniline Composites.” Prog. Org. Coat., 76 639–647 (2013)

Scrinzi, E, Rossi, S, Deflorian, F, Zanella, C, “Evaluation of Aesthetic Durability of Waterborne Polyurethane Coatings Applied on Wood for Interior Applications.” Prog. Org. Coat., 72 81–87 (2011)

Gao, C, Xu, X, Ni, J, Lin, W, Zheng, Q, “Effects of Castor Oil, Glycol Semi-Ester, and Polymer Concentration on the Properties of Waterborne Polyurethane Dispersions.” Polym. Eng. Sci., 49 (1) 162–167 (2009)

Chen, F, Hehl, J, Su, Y, Mattheis, C, Greiner, A, Agarwal, S, “Smart Secondary Polyurethane Dispersions.” Polym. Int., 62 1750–1757 (2013)

Ge, Z, Luo, Y, “Synthesis and Characterization of Siloxane-Modified Two-Component Waterborne Polyurethane.” Prog. Org. Coat., 76 1522–1526 (2013)

Sharmin, E, Zafar, F, Polyurethane: An Introduction, Chap. 1. InTech (2012)

Sultan, M, Bhatti, HN, Zuber, M, Barikani, M, “Synthesis and Characterization of Waterborne Polyurethane Acrylate Copolymers.” Korean J. Chem. Eng., 30 488–493 (2013)

Zhang, S, Miao, W, Yu, ZJ, “Reaction Study of Water-Borne Polyurethanes Based on Isophorone Diisocyanate, Dimethylol Propionic Acid, and Poly(Hexane Neopentyl Adipate Glycol).” Appl. Polym. Sci., 92 161–164 (2004)

Mohamed, HA, Badran, BM, Rabie, AM, Morsi, SMM, “Synthesis and Characterization of Aqueous (Polyurethane/Aromatic Polyamide Sulfone) Copolymer Dispersions from Castor Oil.” Prog. Org. Coat., 77 965–974 (2014)

Desroches, M, Escouvois, M, Auvergne, R, Caillol, S, Boutevin, B, “From Vegetable Oils to Polyurethanes: Synthetic Routes to Polyols and Main Industrial Products.” Polym. Rev., 52 38–79 (2012)

Valero, MF, Gonzalez, A, “Polyurethane Adhesive System from Castor Oil Modified by a Transesterification Reaction.” J. Elastom. Plast., 44 (5) 433–442 (2012)

Mosiewicki, MA, Casado, U, Marcovich, NE, Aranguren, MI, “Polyurethanes From Tung Oil: Polymer Characterization and Composites.” Polym. Eng. Sci., 49 (4) 685–692 (2009)

Hu, S, Wan, C, Li, Y, “Production and Characterization of Biopolyols and Polyurethane Foams From Crude Glycerol Based Liquefaction at Soybean Straw.” Bioresour. Technol., 103 227–233 (2012)

Ataei, S, Yahya, R, Gan, SN, “Coating Performances of Copolymers from a Novel Palm Oil-based Macromer and Methyl Methacrylate.” Pigment Resin Technol., 41 (2) 112–121 (2012)

Hourston, DJ, Williams, GD, Satguru, R, Padget, JC, Pears, D, “The Influence of the Degree of Neutralization, the Ionic Moiety, and the Counterion on Water-Dispersible Polyurethanes.” J. Appl. Polym. Sci., 74 556–566 (1999)

Nanda, AK, Wicks, DA, Madbouly, SA, Otaigbe, JU, “Effect of Ionic Content Solid Content, Degree of Neutralization, and Chain Extension on Aqueous Polyurethane Dispersions Prepared by Prepolymer Method.” J. Appl. Polym. Sci., 98 2514–2520 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohamed, H.A., Morsi, S.M.M., Badran, B.M. et al. Eco-friendly protective coatings based on poly(urethane sulfone amide) dispersions for carbon steel. J Coat Technol Res 14, 437–446 (2017). https://doi.org/10.1007/s11998-016-9861-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-016-9861-x