Abstract

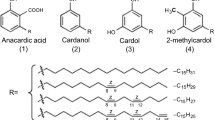

Considering ecological and economical issues in the new generation coating industries, the maximum utilization of naturally occurring materials for polymer synthesis can be an obvious option. In the same line, one of the promising candidates for substituting partially, and to some extent totally, petroleum-based raw materials with an equivalent or even enhanced performance properties, is the Cashew Nut Shell Liquid (CNSL). This dark brown-colored viscous liquid obtained from shells of the cashew nut can be utilized for a number of polymerization reactions due to its reactive phenolic structure and a meta-substituted unsaturated aliphatic chain. Therefore, a wide variety of resins can be synthesized from CNSL, such as polyesters, phenolic resins, epoxy resins, polyurethanes, acrylics, vinyl, alkyds, etc. The present article discusses the potential of CNSL and its derivatives as an environment friendly alternative for petroleum-based raw materials as far as polymer and coating industries are concerned.

Similar content being viewed by others

References

Mukherjee, T, Kao, N, “PLA Based Biopolymer Reinforced with Natural Fibre: A Review.” J. Polym. Environ., 19 (3) 714–725 (2011)

Ahmed, T, Marcal, H, Lawless, M, Wanandy, NS, Chiu, A, Foster, LJR, “Polyhydroxybutyrate and its Copolymer with Polyhydroxyvalerate as Biomaterials: Influence on Progression of Stem Cell Cycle.” Biomacromolecules, 11 (10) 2707–2715 (2010)

Mohanty, AK, Misra, M, Hinrichsen, G, “Biofibres, Biodegradable Polymers and Biocomposites: An Overview.” Macromol. Mater. Eng., 276/277 1–24 (2000)

Zafar, F, Ashraf, SM, Ahmad, S, “Air Drying Polyesteramide from a Sustainable Resource.” Prog. Org. Coat., 51 250–256 (2004)

Pan, X, Sengupta, P, Webster, DC, “High Biobased Content Epoxy-Anhydride Thermosets from Epoxidized Sucrose Esters of Fatty Acids.” Biomacromolecules, 12 (6) 2416–2428 (2011)

Ferrer, CB, Hablot, E, Garrigos, MC, Bocchini, S, Averous, L, Jimenez, A, “Relationship Between Morphology, Properties and Degradation Parameters of Novative Biobased Thermoplastic Polyurethanes Obtained from Dimer Fatty Acids.” Polym. Degrad. Stab., 97 1964–1969 (2012)

Oliveira, WD, Glasser, WG, “Multiphase Materials with Lignin. II. Starlike Copolymers with Caprolactone.” Macromolecules, 27 5–11 (1994)

Li, Y, Mlynar, J, Sarkanen, S, “The First 85% Kraft Lignin-Based Thermoplastics.” J. Polym. Sci. B: Polym. Phys., 35 (12) 1899–1910 (1997)

Cordeiro, N, Aurenty, P, Belgacem, MN, Gandini, A, Neto, CP, “Surface Properties of Suberin.” J. Colloid Interface Sci., 187 498–508 (1997)

Dumont, MJ, Kong, X, Narine, SS, “Polyurethanes from Benzene Polyols Synthesized from Vegetable Oils: Dependence of Physical Properties on Structure.” J. Appl. Polym. Sci., 117 3196–3203 (2010)

Wilson, RJ, The Market for Cashew Nut Kernels and Cashew Nut Shell Liquid. Tropical Products Institute, London, 1975

Araújo, BQ, Saffi, J, Richter, MF, “Antioxidant Properties and Chemical Composition of Technical Cashew Nut Shell Liquid (tCNSL).” Food Chem., 126 1044–1048 (2011)

Lomonaco, D, Maia, FJN, Clemente, CS, Mota, JPF, Mazzetto, SE, “Thermal Studies of New Biodiesel Antioxidants Synthesized from a Natural Occurring Phenolic Lipid.” Fuel, 97 552–559 (2012)

Food and Agriculture Organization of the United Nation, FAOSTAT Data, 2012, www.fao.org.

Hammed, LA, Anikwe, JC, Adedeji, AR, “Cashew Nuts and Production Development in Nigeria.” Am. Eurasian J. Sci. Res., 3 (1) 54–61 (2008)

Hughes, ER, “Method of Expelling the Liquid of Cashew Nut Shells by Heat.” US Patent 2,058,456, 1939

Rector, TM, “Extracting Oil from Cashew Nuts.” US Patent 2,018,091, 1936

Caplan, S, “Cashew Nut Shell liquid and Kernel Oil Separation.” US Patent 2,480,221, 1949

Tyman, JHP, Johnson, RA, Muir, M, Rokhgar, R, “The extraction of natural cashew nut-shell liquid from the cashew nut (Anacardium occidentale).” J. Am. Oil Chem. Soc., 66 553–557 (1989)

Saito, S, “Research Activities on Supercritical Fluid Science and Technology in Japan—A Review.” J. Supercrit. Fluids, 8 177–204 (1995)

Mele, G, Vasapollo, G, “Fine Chemicals and New Hybrid Materials from Cardanol.” Mini. Rev. Chem. Org., 5 243–253 (2008)

Bhunia, HP, Nando, GB, Basak, A, Lenka, S, Nayak, PL, “Synthesis and Characterization of Polymers from Cashew Nut Shell Liquid (CNSL), a Renewable Resource III. Synthesis of a Polyether.” Eur. Polym. J., 35 (9) 1713–1722 (1999)

Patel, RN, Bandyopadhyay, S, Ganesh, A, “Economic Appraisal of Supercritical Fluid Extraction of Refined Cashew Nut Shell Liquid.” J. Chromatogr. A, 1124 (1–2) 130–138 (2006)

Mutasingwa, J, “An Assessment of Cashew Nut Shell Liquid as a Corrosion Inhibitor of Mild Steel Alloys in Flowing Aqueous System”, MSc. Thesis, University of Dar Es Salaam, 2004

Gedam, PH, Sampathkumaran, PS, “Cashew Nut Shell Liquid: Extraction, Chemistry and Application.” Prog. Org. Coat., 14 115–157 (1986)

Akinhanmi, TF, Atasie, VN, “Chemical Composition and Physicochemical Properties of Cashew Nut (Anacardium occidentale) Oil and Cashew Nut Shell Liquid.” J. Agric. Food Environ. Sci., 2 (1) 1–10 (2008)

Paramashivappa, R, Kumar, PP, Vithayathil, PJ, Rao, AS, “Novel Method for Isolation of Major Phenolic Constituents from Cashew (Anacardium occidentale L.) Nut Shell Liquid.” J. Agric. Food Chem., 49 2548–2551 (2001)

Harvey, MT, “Sulphonation Process.” US Patent 2,324,300, 1943

Dawson, R, Wassemian, D, “Nitro-Hydrogenated Cardanols and Process for Preparing Same.” US Patent, 2,502,708, 1950

Shivadasami, HM, “Production of Alkyd Resins.” British Patent 1,279,257, 1972

Unnikrishnan, KP, Thachil, ET, “Synthesis and Characterization of Cardanol-Based Epoxy Systems.” Des. Monom. Polym., 11 (6) 593–607 (2008)

Harvey, MT, “Resin form Cashew Nut Shell Oil.” US Patent 1,725,791, 1929

Harvey, MT, “Substitute for Shellac and the Like.” US Patent 1,725,793, 1929

Caplan, S, “Treatment of Cashew Nut Shell Liquid.” US Patent 2,176,059 (1940).

Groote, MD, Pettingill, OH, “Oxyalkylated Drastically-Oxidized Cashew Nut Shell Liquid and Method of Making Same.” US Patent 2,531,502, 1950

Aggarwal, LK, Thapliyal, PC, Karade, SR, “Anticorrosive Properties of the Epoxy-Cardanol Resin based Paints.” Prog. Org. Coat., 59 76–80 (2007)

Huang, K, Zhang, Y, Li, M, Lian, J, Yang, X, Xia, J, “Preparation of a Light Color Cardanol-Based Curing Agent and Epoxy Resin Composite: Cure-Induced Phase Separation and Its Effect on Properties.” Prog. Org. Coat., 74 240–247 (2012)

Kim, YH, An, ES, Park, SY, Song, BK, “Enzymatic Epoxidation and Polymerization of Cardanol obtained from a Renewable Resource and Curing of Epoxide-containing Polycardanol.” J. Mol. Catal. B: Enzym., 45 39–44 (2007)

Campaner, P, D’Amico, D, Longo, L, Stifani, C, Tarzia, A, “Cardanol-Based Novolac Resins as Curing Agents of Epoxy Resins.” J. Appl. Polym. Sci., 114 3585–3591 (2009)

Pathak, SK, Rao, BS, “Structural Effect of Phenalkamines on Adhesive Viscoelastic and Thermal Properties of Epoxy Networks.” J. Appl. Polym. Sci., 102 4741–4748 (2006)

Tan, TTM, Nieu, NH, “Carbon Fiber Cardanol-Epoxy Composites.” J. Appl. Polym. Sci., 61 133–137 (1996)

Madhusudhan, V, Murthy, BGK, “Polyfunctional Compounds from Cardanol.” Prog. Org. Coat., 20 63–71 (1992)

Tan, TTM, “Cardanol–Glycols and Cardanol–Glycol-Based Polyurethane Films.” J. Appl. Polym. Sci., 65 507–510 (1997)

Mythili, CV, Retna, AM, Gopalakrishnan, S, “Physical, Mechanical, and Thermal Properties of Polyurethanes Based on Hydroxyalkylated Cardanol–Formaldehyde Resins.” J. Appl. Polym. Sci., 98 284–288 (2005)

Rekha, N, Asha, SK, “Synthesis and FTIR Spectroscopic Investigation of the UV Curing Kinetics of Telechelic Urethane Methacrylate Crosslinkers Based on the Renewable Resource-Cardanol.” J. Appl. Polym. Sci., 109 2781–2790 (2008)

Mahanwar, PA, Kale, DD, “Effect of Cashew Nut Shell Liquid (CNSL) on Properties of Phenolic Resins.” J. Appl. Polym. Sci., 61 2107–2111 (1996)

Papadopoulou, E, Chrissafis, K, “Thermal Study of Phenol–Formaldehyde Resin Modified with Cashew Nut Shell Liquid.” Thermochim. Acta, 512 105–109 (2011)

Misra, AK, Pandey, GN, “Kinetics of Alkaline-Catalyzed Cardanol–Formaldehyde Reaction. I.” J. Appl. Polym. Sci., 29 361–372 (1984)

Misra, AK, Pandey, GN, “Kinetics of Alkaline-Catalyzed Cardanol–Formaldehyde Reaction. II. Mechanism of the Reaction.” J. Appl. Polym. Sci., 30 969–977 (1985)

Misra, AK, Pandey, GN, “Kinetics of Alkaline-Catalyzed Cardanol–Formaldehyde Reaction. I. Determination of Composition of the Resin.” J. Appl. Polym. Sci., 30 979–983 (1985)

Sultania, M, Rai, JSP, Srivastava, D, “A Study on the Kinetics of Condensation Reaction of Cardanol and Formaldehyde, Part I.” Int. J. Chem. Kinet., 41 559–572 (2009)

Nimuru, N, Miyakoshi, T, “Structural Characterization of Cashew Resin Film Using Two-Stage Pyrolysis-Gas Chromatography/Mass Spectrometry.” Int. J. Polym. Anal. Charact., 8 47–66 (2003)

Roy, D, Basu, PK, Raghunathan, P, Eswaran, SV, “Cashew Nut Shell Liquid–based Tailor-Made Novolac Resins: Polymer Morphology Quantitation by 1-D and 2-D NMR Techniques and Performance Evaluation.” J. Appl. Polym. Sci., 89 1959–1965 (2003)

Cardona, F, Tak, ALK, Fedrigo, J, “Novel Phenolic Resins with Improved Mechanical and Toughness Properties.” J. Appl. Polym. Sci., 123 2131–2139 (2012)

Souza, FG, Michel, RC, Pinto, JC, Cosme, T, Oliveira, GE, “Effect of Pressure on the Structure and Electrical Conductivity of Cardanol–Furfural–Polyaniline Blends.” J. Appl. Polym. Sci., 119 2666–2673 (2011)

Prabhakaran, K, Narayan, A, Pvithran, C, “Cardanol as a Dispersant Plasticizer for an Alumina/Toluene Tape Casting Slip.” J. Eur Ceram. Soc., 21 2873 (2001)

Pillai, C, Prasad, V, Sudha, J, Bera, S, Menon, A, “Polymeric Resins from Renewable Resources. II. Synthesis and Characterization of Flame-Retardant Prepolymer from Cardanol.” J. Appl. Polym. Sci., 41 2487 (1990)

Bhunia, H, Nando, G, Chakib, T, “Synthesis and Characterization of Polymers from Cashew Nut Shell Liquid (CNSL), a Renewable Resource II. Synthesis of Polyurethanes.” Eur. Polym. J., 35 1381 (1999)

Frigone, M, Masica, L, Aciermo, D, “Oligomeric and Polymeric Modifiers for Toughening of Epoxy Resins.” Eur. Polym. J, 31 1021 (1995)

Tripathi, G, Srivastava, D, “Effect of Carboxyl-terminated Poly(butadiene-co-acrylonitrile) (CTBN) Concentration on Thermal and Mechanical Properties of Binary Blends of Diglycidyl Ether of Bisphenol-A (DGEBA) Epoxy Resin.” Mater. Sci. Eng: A, 443 (1–2) 262–269 (2007)

Pearson, R, Yee, A, “Toughening Mechanisms in Elastomer-modified Epoxies—Part 3. The Effect of Cross-link Density.” J. Mater. Sci., 24 2571–2580 (1989)

May, C, Epoxy Resin—Chemistry and Technology. Marcel Dekker, New York (1988)

Yadav, R, Srivastava, D, “Studies on Cardanol-based Epoxidized Novolac Resin and Its Blends.” Chem. Chem. Technol., 2 (3) 173–184 (2008)

Kim, DS, Kim, YH, An, ES, Song, BK, Chelikani, R, “Polymerization of Cardanol using Soybean Peroxidase and its Potential Application as Anti-bio Film Coating Material.” Biotechnol. Lett., 25 (18) 1521 (2003)

Choi, YH, Kim, JC, Ahn, JK, Ko, SY, Kim, DH, Lee, TY, “Anti-biofouling Behaviour of Natural Unsaturated Hydrocarbon Phenols Impregnated in PDMS Matrix.” J. Ind. Eng. Chem., 14 292–296 (2008)

More, AS, Sane, PS, Patil, AS, Wadgaonkar, PP, “Synthesis and Characterization of Aromatic Polyazomethines Bearing Pendant Pentadecyl Chains.” Polym. Degrad. Stab., 95 1727–1735 (2010)

Ravichandran, S, Bouldin, RM, Kumar, J, Nagarajan, R, “A Renewable Waste Material for the Synthesis of a Novel Non-Halogenated Flame Retardant Polymer.” J Clean Prod., 19 454–458 (2011)

Bai, W, Xiao, X, Chen, Q, Xu, Y, Zheng, S, Lin, J, “Synthesis and Characterization of Cross-linked Polymer from Cardanol by Solvent-Free Grinding Polymerization.” Prog. Org. Coat., 75 184–189 (2012)

Kim, YH, Won, K, Kwon, JM, Jeong, HS, Park, SY, An, ES, Song, BK, “Synthesis of Polycardanol from a Renewable Resource Using a Fungal Peroxidase from Coprinus cinereus.” J. Mol. Catal. B: Enzym., 34 33–38 (2005)

Rao, BS, Palanisamy, A, “A New Thermoset System Based on Cardanol Benzoxazine and Hydroxy Benzoxazoline with Lower Cure Temperature.” Prog. Org. Coat., 74 427–434 (2012)

Ramasri, M, Rao, GSS, Sampathkumaran, PS, Shirsalkar, MM, “Synthesis and Characterization of Mannich Bases from Cardbisphenol.” J. Appl. Polym. Sci., 39 1993–2004 (1990)

More, AS, Patil, AS, Wadgaonkar, PP, “Poly(amideimide)s Containing Pendant Pentadecyl Chains: Synthesis and Characterization.” Polym. Degrad. Stab., 95 837–844 (2010)

Philip, JYN, Buchweishaija, J, Mkayula, LL, Ye, L, “Preparation of Molecularly Imprinted Polymers Using Anacardic Acid Monomers Derived from Cashew Nut Shell Liquid.” J. Agric. Food Chem., 55 (22) 8870–8876 (2007)

Kim, S, “The Reduction of Formaldehyde and VOCs Emission from Wood-Based Flooring by Green Adhesive using Cashew Nut Shell Liquid (CNSL).” J. Hazard. Mater., 182 919–922 (2010)

Lee, JH, Jeon, J, Kim, S, “Green Adhesives Using Tannin and Cashew Nut Shell Liquid for Environment-Friendly Furniture Materials.” J. Korea Furnit. Soc., 22 (3) 219–229 (2011)

Sridhar, S, Cadlince, P, Ratra, MC, “Laminating Resol Varnishes Made with Crude Multivalent Phenol.” J. Appl. Polym. Sci., 47 797–804 (1993)

Greco, A, Brunetti, D, Renna, G, Mele, G, Maffezzoli, A, “Plasticizer for Poly(vinyl chloride) from Cardanol as a Renewable Resource Material.” Polym. Degrad. Stab., 95 2169–2174 (2010)

Dantas, TNC, Dantas, MSG, Neto, AAD, D’Ornellas, CV, Queiroza, LR, “Novel Antioxidants from Cashew Nut Shell Liquid Applied to Gasoline Stabilization.” Fuel, 82 1465–1469 (2003)

Facanha, MAR, Mazzetto, SE, Carioca, JOB, De Barros, GG, “Evaluation of Antioxidant Properties of a Phosphorated Cardanol Compound on Mineral Oils (NH10 and NH20).” Fuel, 86 2416–2421 (2007)

Lomonaco, D, Maia, FJN, Clemente, CS, Mota, JPF, Mazzetto, SE, “Plasticizer for Poly(vinyl chloride) from Cardanol as a Renewable Resource Material.” Fuel, 97 552–559 (2012)

Achary, PGR, Mohanty, N, Guru, BN, Pal, NC, “Synthesis and Thermal Degradation Study of Polymer blends from Polyurethanes of Linseed Oil and Cardanol Based Dyes with Aminophenols.” J. Chem. Pharm. Res., 4 (3) 1475–1485 (2012)

Gopalakrishnan, S, Nevaditha, NT, Mythili, CV, “Thermal Degradation and XRD Studies of Diazotised-p-Sulphanilic Acid Dye Based Resins Synthesized from Renewable Resource.” Arch. Appl. Sci. Res., 4 (2) 1091–1099 (2012)

Paebumrung, P, Petsom, A, Thamyongkit, P, “Cardanol-Based Bis(azo) Dyes as a Gasoline 91 Colorant.” J. Am. Oil. Chem. Soc., 89 321–328 (2012)

Philip, JYN, Buchweishaija, J, Mkayula, LL, “Cashew Nut Shell Liquid as an Alternative Corrosion Inhibitor for Carbon Steels.” Tanzan. J. Sci., 28 (2) 9–19 (2002)

Suryanarayan, SS, Satish, N, Anita, N, “Study of Sodium Salt of Cashew Nut Shell Liquid (CNSL) as an Alternate Dispersant in Coating of Paper.” IPPTA, 24 (2) 119–122 (2012)

Mark, HF, “Silane Coupling Agents.” In: Rogers, ME, Long, TE, (eds.) Encyclopedia of Polymer Science and Technology, 3rd ed., Vol. 8, pp. 38–49. Wiley, New York, 2004

Tanaka, S, Iji, M, “Cardanol-Modified Silane Coupling Agent, Cardanol-Modified Filler, and Cellulose Resin Composition.” US Patent 0036940 A1, 2013

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balgude, D., Sabnis, A.S. CNSL: an environment friendly alternative for the modern coating industry. J Coat Technol Res 11, 169–183 (2014). https://doi.org/10.1007/s11998-013-9521-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-013-9521-3