Abstract

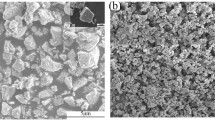

This article deals with the treatment of barium sulfate extender pigment with iron oxide and its phenomenological adsorption mechanism in the presence of H+ and OH− ions in solution. The pH range taken in the present study is 5–6. By depositing a ferric oxide layer on barium sulfate particles a novel pigment with better optical and functional performance is obtained. This pigment in various coating systems improves physicochemical performance and acts as an active barrier. The treated pigments can be suitably used in different architectural and industrial coatings. The experimental techniques of surface treatment are discussed, along with the instrumental analysis by SEM, EDAX, XRD, etc.

Similar content being viewed by others

References

Dondi, M, Matteucci, F, Cruciani, G, Gasparotto, G, Tobaldi, DM, “Pseudobrookite Ceramic Pigments: Crystal Structural, Optical and Technological Properties.” Solid State Sci., 9 (5) 362–369 (2007)

Baldi, G, Barzanti, A, Cruciani, G, Zama, A, Bianchi, CL, “Gray-Blue Al2O3-MoOX Ceramic Pigments: Crystal Structure, Colouring Mechanism and Performance.” Dyes Pigm., 76 (1) 179–186 (2008)

Rose Sr., GR, John, MR, “Flocculation.” In: Mark, HF (ed.) Encyclopedia of Polymer Science and Engineering, 2nd ed., Vol. 7, p. 211. Wiley, New York (1987)

Freeman, GM, Lynch, TJ, Prowell, CD, Outlaw, DE, “Surface Treated Barium Sulphate and Method of Preparing the Same”, [online]. 6194070 (US patent), available from: www.patentstrom.us/search/advanced.html, p. 1 (2001)

Nylen, P, Sunderland, E, Modern Surface Coating, p. 464. John Wiley and Sons, New York, NY, 1969

Zan, L, Zhong, J, Luo, S, “The Preparation and Characteristics of Cobalt Blue Mica Coated Titania.” J. Inorg. Chem., 142 289 (1999)

German, RM, Munir, ZA, “Surface Area Reduction During Isothermal Sintering.” J. Am. Ceram. Soc., 59 379–383 (1970)

Dondi, M, Matteucci, F, Cruciani, G, Gasparotto, G, Tabalco, DM, “Crystal Structure, Optical Properties and Colouring Performance of Karrite MgTi2O5 Ceramic Pigments.” J. Solid State Chem., 180 (11) 3196–3210 (2007)

He, T, Becker, KD, “An Optical In-Situ Study of a Reacting Spinel Crystal.” Solid State Ionics, 101–103 337–342 (1997)

Kim, DS, Han, SJ, Kwak, SY, “Synthesis and Photocatalytic Activity of Mesoporous TiO2 with the Surface Area, Crystallite Size, and Pore Size.” J. Colloid Interface Sci., 316 (1) 85–91 (2008)

Vasiliev, OP, Faure, B, Ng, JBS, Baegstrom, L, “Colloidal Aspects Relating to Direct Incorporation of TiO2 Nanoparticles into Mesoporous Spheres by an Aerosol-Assisted Process.” J. Colloid Interface Sci., 319 (1) 144–151 (2008)

Sheng, XX, Ting, YP, Pehkonen, SO, “The Influence of Ionic Strength, Nutrients and pH on Bacterial Adhesion to Metals.” J. Colloid Interface Sci., 321 (2) 256–264 (2008)

Hiemstra, T, Van Riemsdijk, WH, “On the Relationship Between Charge Distribution, Surface Hydration, and the Structure of the Interface of Metal Hydroxides.” J. Colloid Interface Sci., 301 (1) 1–18 (2006)

Fonseca, GS, Machado, G, Teixeira, SR, Fecher, GH, Morais, J, Alves, MCM, Dupont, J, “Synthesis and Characterization of Catalytic Iridium Nano-Particle in Imidazolium Ion Liquids.” J. Colloid Interface Sci., 301 (1) 193–204 (2008)

Gupta, SS, Khattacharyya, KG, “Adsorption of Ni (II) on Clays.” J. Colloid Interface Sci., 295 (1) 21–32 (2006)

Bradi, HB, “Adsorption of Heavy Metal Ions on Soils and Soils Constituents.” J. Colloid Interface Sci., 277 (1) 1–18 (2004)

Kim, MS, Chung, JG, “A Study on the Adsorption Characteristics of Orthophosphates on Rutile-Type Titanium Dioxide in Aqueous Solutions.” J. Colloid Interface Sci., 233 31–37 (2001)

Zhu, J, Wu, S, The preparation and characteristics of cobalt blue mica coated titania. The Principal Technology, Beijing Publication, Beijing, 1996

Jhu, JL, Wu, SN, Pigment Technology, 3rd ed., pp. 567–570. Chemical Industry Press, Beijing, 1994

Liu, YZ, Manual for Physicochemical Properties of Inorganic Substances and Important Reaction Equations, 1st ed. Chengu Science and Technology University Press, Chengu, 1993

Yan, GJ, Zhang, JC, Chun, SL, Cheng, J, “Research on Complex Cobalt Blue Pigment.” Bull. Chin. Ceram. Soc., 3 17–20 (2000)

Yang, J, Cheng, JJ, Zhang, JC, “Effects of Cations on the Reflectivity of Complex Cobalt Blue Pigment.” J. East China Univ. Sci. Technol., 26 (4) 291–293 (2000)

Junru, T, Yunfang, H, Wenxiang, H, Chen, X, Fun, X, “The Preparation and Characteristics of a Multi-Cover-Layer Type, Blue Mica Titania, Pearlescent Pigment.” Dyes Pigm., 52 215–217 (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, M., Kamani, P.K. & Shukla, R.K. The preparation and characteristics of surface treated barium sulfate extender pigment. J Coat Technol Res 10, 189–198 (2013). https://doi.org/10.1007/s11998-012-9433-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-012-9433-7