Abstract

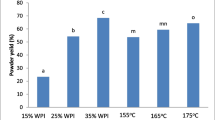

Benzoic acid is widely used as a preservative in the food and feed industry, and microencapsulation is important in the application of this ingredient in various food products. The objective of this work was to evaluate the effect of benzoic acid concentration and drying air temperature on the physical characteristics of powders produced by spray drying, using maltodextrin and modified starch as the wall materials. A rotatable central composite design was used; the independent variables were inlet air temperature (145–180 °C) and benzoic acid concentration (2–10 %, m/m). Maximum yield was obtained when higher concentrations of benzoic acid and higher inlet air temperatures were applied. The highest microencapsulation efficiency was reached at intermediate temperatures (160 °C) and low concentration of benzoic acid. The particles size (D [4,3]) ranged from 24.99 to 29.52 μm and, in general, presented amorphous structure, spherical shape with rough surfaces and had no cracks The optimum condition, considering all the response variables together, was drying air temperature 169 °C and benzoic acid concentration 6 % (m/m). Under these conditions, the particles presented solubility of 75.96 g/100 g and wettability of 56.8 s/g. Moreover, the process showed microencapsulation efficiency of 76.77 g/100 g and yield of 40.1 %. Spray drying was considered a potential process to provide microencapsulated benzoic acid.

Similar content being viewed by others

References

Amado, I. R., Vázquez, J. A., Murado, M. A., & González, M. P. (2015). Recovery of astaxanthin from shrimp cooking wastewater: optimization of astaxanthin extraction by response surface methodology and kinetic studies. Food and Bioprocess Technology, 8, 371–381.

AOAC (2000). ASSOCIATION OF OFFICIAL ANALITICAL CHEMISTRY. Official methods of analysis of the association of chemstry (17 ed.). Washington: Association of Official Analitical Chemistry.

Abadio, F. D. B., Domingues, A. M., Borges, S. V., & Oliveira, V. A. (2004). Physical properties of powdered pineapple (Ananas comosus) juice-effect of maltdextrin concentration and atomization speed. Journal of Food Engineering, 64(3), 285–287.

Bae, E. K., & Lee, S. J. (2008). Microencapsulation of avocado oil by spray drying using whey protein and maltodextrin. Journal of Microencapsulation, 25(8), 549–560.

Bakar, J., Ee, S. C., Muhammad, K., Hashim, D. M., & Adzahan, N. (2013). Spray-drying optimization for red pitaya peel (Hylocereus polyrhizus). Food and Bioprocess Technology, 6, 1332–1342.

Bas, D., & Boyaci, I. H. (2007). Modeling and optimization I: usability of response surface methodology. Journal of Food Engineering, 78(3), 836–845.

Basu, S., Shivhare, U. S., & Mujumdar, A. S. (2006). Models for sorption isotherms for foods: a review. Drying Technology, 24(8), 917–930.

Bhandari, B. R., & Hartel, R. W. (2005). Phase transitions during food powder production and powder stability. In C. Onwulata (Ed.), Encapsulated and powdered foods (pp. 261–292). New York: Taylor & Francis.

Boonyai, P., Howes, T., & Bhandari, B. (2006). Applications of the cyclone stickiness test for characterization of stickiness in food powders. Drying Technology, 24(6), 703–709.

Borrmann, D., Pierucci, A. P. T. R., Leite, S. G. F., & Leão, M. H. M. R. (2013). Microencapsulation of passion fruit (Passiflora) juice with n-octenylsuccinate-derivatised starch using spray-drying. Food and Bioproducts Processing, 91(1), 23–27.

Botrel, D. A., Borges, S. V., Fernandes, R. V. B., Viana, A. D., Costa, J. M. G., & Marques, G. R. (2012). Evaluation of spray drying conditions on properties of microencapsulated oregano essential oil. International Journal of Food Science and Technology, 47, 2289–2296.

Buffo, R. A., Probst, K., Zehentbauer, G., Luo, Z., Reineccius, G. A. (2002). Effects of agglomeration on the properties of spray-dried encapsulated flavours. Flav. Fragr. J., 17, 292-299.

Cai, Y. Z., & Corke, H. (2000). Production and properties of spray-dried Amaranthus betacyanin pigments. Journal of Food Science, 65(7), 1248–1252.

Cano-Chauca, M., Stringheta, P. C., Ramos, A. M., & Cal-Vidal, J. (2005). Effect of the carriers on the microstructure of mango powder obtained by spray drying and its functional characterization. In. Food Sci. Emerg. Technol., 6(4), 420–428.

Caparino, O. A., Tang, J., Nindo, C. I., Sablani, S. S., Powers, J. R., & Fellman, J. K. (2012). Effect of drying methods on the physical properties and microstructures of mango (Philippine ‘Carabao’var.) powder. J. Food Eng., 111(1), 135–148.

Chakraborty, S., Rao, P. S., & Mishra, H. N. (2014). Effect of ph on enzyme inactivation kinetics in high-pressure processed pineapple (Ananas comosus l.) puree using response surface methodology. Food and Bioprocess Technology, 7, 3629–3645.

Cuq, B., Rondet, E., & Abecassis, J. (2011). Food powders engineering, between knowhow and science: constraints, stakes and opportunities. Powder Technology, 208(2), 244–251.

Derringer, G., & Suich, R. (1980). Simultaneous optimization of several response variables. Journal of Quality Technology, 12(4), 214–219.

Drusch, S., Serfert, Y., Heuvel, A. V. D., & Schwarz, K. (2006). Physicochemical characterization and oxidative stability of fish oil encapsulated in an amorphous matrix containing trehalose. Food Research International, 39(7), 807–815.

Fazaeli, M., Emam-Djomeh, Z., Ashtari, A. K., & Omid, M. (2012). Effect of spray drying conditions and feed composition on the physical properties of black mulberry juice powder. Food and Bioproducts Processing, 90(4), 667–675.

Fernandes, R. V. B., Borges, S. V., Botrel, D. A., & Oliveira, C. R. (2014). Physical and chemical properties of encapsulated rosemary essential oil by spray drying using whey protein-inulin blends as carriers. International Journal of Food Science and Technology, 49(6), 1522–1529.

Fernandes, R. V. B., Borges, S. V., Botrel, D. A., Silva, E. K., Costa, J. M. G., & Queiroz, F. (2013). Microencapsulation of rosemary essential oil: characterization of particles. Drying Technology, 31, 1245–1254.

Fuchs, M., Turchiuli, C., Bohin, M., Cuvelier, M. E., Ordonnaud, C., Peyrat-Maillard, M. N., & Dumoulin, E. (2006). Encapsulation of oil in powder using spray drying and fluidised bed agglomeration. J. Food Eng, 75, 27–35.

Gharsallaoui, A., Roudaut, G., Chambin, O., Voilley, A., & Saurel, R. (2007). Applications of spray-drying in microencapsulation of food ingredients: an overview. Food Research International, 40(9), 1107–1121.

Gorle, B. S. K., Smirnova, I., & Arlt, W. (2010). Adsorptive crystallization of benzoic acid in aerogels from supercritical solutions. J. Supercri Fluids, 52, 249–257.

Goula, A. M., & Adamopoulos, K. G. (2010). A new technique for spray drying orange juice concentate. Inn. Food Sci. Emerg. Technol., 11(2), 342–351.

Goula, A. M., & Adamopoulus, K. G. (2008). Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: I. Drying kinetics and product recovery. Drying Technology, 26(6), 714–725.

Goula, A. M., & Adamopoulos, K. G. (2004). Spray drying of tomato pulp: effect of feed concentration. Drying Technology, 22(10), 2309–2330.

Hancock, B. C., & Zografi, G. (1997). Characteristics and significance of the amorphous state in pharmaceutical systems. Journal of Pharmaceutical Sciences, 86, 1–12.

Jinapong, N., Suphantharika, M., & Jamnong, P. (2008). Production of instant soymilk powders by ultrafiltration, spray drying and fluidized bed agglomeration. Journal of Food Engineering, 84(2), 194–205.

Kim, E. H. J., Chen, X. D., & Pearce, D. (2002). Surface characterization of four industrial spray-dried dairy powders in relation to chemical composition, structure and wetting property. Colloids Surf. B: Biointerfaces., 26(3), 197–212.

Kha, T. C., Nguyen, M. H., Roach, P. D., & Stathopoulos, C. E. (2014). Microencapsulation of gac oil: optimisation of spray drying conditions using response surface methodology. Powder Technology, 264, 298–309.

Langrish, T. A. G., & Wang, S. (2009). Crystallization rates for amorphous sucrose and lactose powders from spray drying: a comparison. Drying Technology, 27(4), 606–614.

Lannes, S. C. S., & Medeiros, M. L. (2003). Processamento de achocolatado de cupuaçu por spray-dryer. Rev. Bras. Ciênc. Farm., 39(1), 115–123.

Leimann, F. V., Gonçalves, O. H., Machado, R. A. F., & Bolzan, A. (2009). Antimicrobial activity of microencapsulated lemongrass essential oil and the effect of experimental parameters on microcapsules size and morphology. Mater. Sci. Eng, C., 29(2), 430–436.

Marques, G. R., Borges, S. V., Botrel, D. A., Costa, J. M. G., Silva, E. K., & Corrêa, J. L. G. (2014a). Spray drying of green corn pulp. Drying Technology, 32(7), 861–868.

Marques, G. R., Borges, S. V., Mendonça, K. S., Fernandes, R. V. B., & Menezes, E. G. T. (2014b). Application of maltodextrin in green corn extract powder production. Powder Technology, 263, 89–95.

Medina-Torres, L., García-Cruz, E. E., Calderas, F., González Laredo, R. F., Sánchez-Olivares, G., Gallegos-Infante, J. A., Rocha-Guzmán, N. E., & Rodrígues-Ramírez, J. (2013). Microencapsulation by spray drying of gallic acid with nopal mucilage (Opuntia fícus indica). LWT-Food. Sci. Technol., 50(2), 642–650.

Moreira, G. E. G., Costa, M. G. M., Souza, A. C. R., Brito, E. S., Medeiros, M. F. D., & Azeredo, H. M. C. (2009). Physical properties of spray dried acerola pomace extract as affected by temperature and drying aids. LWT-Food. Sci. Technol., 42(2), 641–645.

Ohtsuki, T., Sato, K., Sugimoto, N., Akiyama, H., & Kawamura, Y. (2012). Absolute quantification for benzoic acid in processed foods using quantitative proton nuclear magnetic resonance spectroscopy. Talanta, 99(15), 342–348.

Palma-Rodrigues, H. M., Agama-Acevedo, E., Gonzalez-Soto, R. A., Vernon-Carter, E. J., Alvarez-Ramirez, J., & Bello-Perez, L. A. (2013). Ascorbic acid microencapsulation by spray-drying in native and acid-modified starches from different botanical sources. Starch–Staärke., 65(7–8), 584–592.

Patil, V., Chauhan, A. K., & Singh, R. P. (2014). Optimization of the spray-drying process for developing guava powder using response surface methodology. Powder Technology, 253, 230–236.

Pereira, H. V. R., Saraiva, K. P., Carvalho, L. M. J., Andrade, L. R., Pedrosa, C., & Pierucci, A. P. T. R. (2009). Legumes seeds protein isolates in the production of ascorbic acid microparticles. Food Research International, 42(1), 115–121.

Quek, S. Y., Chok, N. K., & Swedlund, P. (2007). The physicochemical properties of spray-dried watermelon powder. Chem. Eng. Proc.: Process. Intensif., 46(5), 386–392.

Ré, M. I. (1998). Microencapsulation by spray drying. Drying Technology, 16(6), 1195–1236.

Reineccius, G. A. (2004). The spray drying of food flavors. Drying Technology, 22, 1289–1324.

Reineccius, T. A., Reineccius, G. A., & Peppard, T. L. (2004). Utilization of β-Cyclodextrin for improved flavor retention in thermally processed foods. J. Food Sci. Chicago., 69(1), FCT58–FCT62.

Robert, P., García, P., Reyes, N., Chávez, J., & Santos, J. (2012). Acetylated starch and inulin as encapsulating agents of gallic acid and their release behaviour in a hydrophilic system. Food Chemistry, 134(1), 1–8.

Rodrigues, M.I., & Iemma, A.F. (2011). Experimental Design and Process Optimization. Ed. Casa do Espírito Amigo Fraternidade Fé e Amor, Campinas, SP, Brazil. 352.

Sansone, F., Mencherini, T., Picemo, P., D’Amore, M., Aquino, R. P., & Lauro, M. R. (2011). Maltodextrin/pectin microparticles by spray drying as carrier for nutraceutical extracts. Journal of Food Engineering, 105(3), 468–476.

Santos, A. B., Fávaro-Trindade, C. S., & Grosso, C. R. F. (2005). Preparo e caracterização de microcápsulas de oleoresina de páprica obtidas por atomização. Ciênc. Tecnol. Aliment. Campinas., 25(2), 322–326.

Souza, A. S., Borges, S. V., Magalhães, N. F., Ricardo, H. V., Cereda, M. P., & Daiuto, E. R. (2009). Influence of spray drying conditions on the physical properties of dried pulp tomato. Ciênc. Tecnol. Aliment. Campinas., 29(2), 291–294.

Teixeira, M. I., Andrade, L. R., Farina, M., & Rocha-Leão, M. H. M. (2004). Characterization of short chain fatty acid microcapsules produced by spray drying. Mater. Sci. Eng. C., 24(5), 653–658.

Tfouni, S. A. V., & Toledo, M. C. F. (2002). Determination of benzoic and sorbic acids in brazilian food. Food Control, 13(2), 117–123.

Truong, V., Bhandari, B. R., Howes, T. (2005). Optimisation of co-current spray drying process of sugar-rich foods. Part II–optimisation of spray drying process based on glass transition temperature. J. Food Eng., 71(1), 66–72.

Vardin, H., & Yasar, M. (2012). Optimisation of pomegranate (Punica granatum L.) juice spray-drying as affected by temperature and maltodextrin content. Int. J. Food Sci. Technol., 47(1), 167–176.

Vasconcelos, E. A. F., Medeiros, M. G. F., Raffin, F. N., & Moura, T. F. A. L. (2005). Influência da temperatura de secagem e da concentração de Aerosil ®200 nas características de extratos secos por aspersão da Schinus terebinthifolius Raddi (Anacardiaceae). Rev. Bras. Farmacogn., 15(3), 243–249.

Walton, D. E., & Mumford, C. J. (1999). The morphology of spray-dried particles: the effect of process variables upon the morphology of spray-dried particles. Chem. Eng. Res. Design., 77(5), 442–460.

Yoon, H. J., Cho, Y. H., Park, J., Lee, C. H., Park, S. K., Cho, Y. J., Han, K. W., Lee, J. O., & Lee, C. W. (2003). Assessment of estimated daily intakes of benzoates for average and high consumers in Korea. Food Additives and Contaminants, 20(2), 127–135.

Yu, L. (2001). Amorphous pharmaceutical solids: preparation, characterization and stabilization. Advanced Drug Delivery Reviews, 48(1), 27–42.

Acknowledgment

The authors thank the Foundation for Research of the State of Minas Gerais, Brazil (FAPEMIG) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Marques, G.R., Fernandes, R.V.d., Borges, S.V. et al. Influence of Spray-Drying Conditions on Physical and Morphological Characteristics of Microencapsulated Benzoic Acid. Food Bioprocess Technol 9, 1969–1978 (2016). https://doi.org/10.1007/s11947-016-1784-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-016-1784-0