Abstract

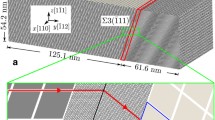

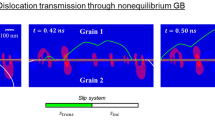

Slip transfer via sequential pile-up dislocations across grain boundaries (GBs) plays an important role in plastic deformation in polycrystalline face-centered cubic (FCC) metals. In this work, large scale concurrent atomistic-continuum (CAC) method simulations are performed to address the slip transfer of mixed character dislocations across GBs in FCC Ni. Two symmetric tilt GBs, a Σ3{111} coherent twin boundary (CTB) and a Σ11{113} symmetric tilt GB (STGB), are investigated using five different fits to the embedded-atom method (EAM) interatomic potential to assess the variability of predicted dislocation-interface reaction. It is shown that for the Σ3 CTB, two of these potentials predict dislocation transmission while the other three predict dislocation absorption. In contrast, all five fits to the EAM potential predict that dislocations are absorbed by the Σ11 STGB. Simulation results are examined in terms of several slip transfer criteria in the literature, highlighting the complexity of dislocation/GB interactions and the significance of multiscale modeling of the slip transfer process.

Similar content being viewed by others

References

J.P. Hirth and J. Lothe, Theory of Dislocations (Hoboken: Wiley, 1982).

S. Xu, L. Xiong, Y. Chen, and D.L. McDowell, npj Comput. Mater. 2, 15016 (2016).

J. Wang, JOM 67, 1515 (2015).

D.E. Spearot and M.D. Sangid, Curr. Opin. Solid State Mater. Sci. 18, 188 (2014).

J. Kacher and I.M. Robertson, Acta Mater. 60, 6657 (2012).

J. Kacher, B.P. Eftink, B. Cui, and I.M. Robertson, Curr. Opin. Solid State Mater. Sci. 18, 227 (2014).

D.L. McDowell, Int. J. Plast 26, 1280 (2010).

B. Liu, D. Raabe, P. Eisenlohr, F. Roters, A. Arsenlis, and G. Hommes, Acta Mater. 59, 7125 (2011).

M. Dewald and W. Curtin, Model. Simul. Mater. Sci. Eng. 19, 055002 (2011).

M.P. Dewald and W.A. Curtin, Philos. Mag. 87, 4615 (2007).

W. Yu and Z. Wang, Comput. Mater. Sci. 87, 150 (2014).

Y. Chen, J. Chem. Phys. 130, 134706 (2009).

L. Xiong, G. Tucker, D.L. McDowell, and Y. Chen, J. Mech. Phys. Solids 59, 160 (2011).

S. Xu, R. Che, L. Xiong, Y. Chen, and D.L. McDowell, Int. J. Plast 72, 91 (2015).

L. Xiong, S. Xu, D.L. McDowell, and Y. Chen, Int. J. Plast 65, 33 (2015).

L. Xiong, J. Rigelesaiyin, X. Chen, S. Xu, D.L. McDowell, and Y. Chen, Acta Mater. 104, 143 (2016).

S. Xu, L. Xiong, Y. Chen, and D.L. McDowell, Acta Mater. 122, 412 (2017).

S. Xu, L. Xiong, Y. Chen, and D.L. McDowell, Scr. Mater. 123, 135 (2016).

S. Xu, L. Xiong, Y. Chen, and D.L. McDowell, J. Mech. Phys. Solids 96, 460 (2016).

M.D. Sangid, T. Ezaz, H. Sehitoglu, and I.M. Robertson, Acta Mater. 59, 283 (2011).

M. Chassagne, M. Legros, and D. Rodney, Acta Mater. 59, 1456 (2011).

Z.H. Jin, P. Gumbsch, E. Ma, K. Albe, K. Lu, H. Hahn, and H. Gleiter, Scr. Mater. 54, 1163 (2006).

Z.H. Jin, P. Gumbsch, K. Albe, E. Ma, K. Lu, H. Gleiter, and H. Hahn, Acta Mater. 56, 1126 (2008).

W. Yu and Z. Wang, Philos. Mag. 94, 2224 (2014).

Y. Mishin, D. Farkas, M.J. Mehl, and D.A. Papaconstantopoulos, Phys. Rev. B 59, 3393 (1999).

J.E. Angelo, N.R. Moody, and M.I. Baskes, Model. Simul. Mater. Sci. Eng. 3, 289 (1995).

S.M. Foiles and J.J. Hoyt, Acta Mater. 54, 3351 (2006).

A.F. Voter and S.P. Chen, Mater. Res. Soc. Symp. Proc. 82, 175 (1987).

X.W. Zhou, R.A. Johnson, and H.N.G. Wadley, Phys. Rev. B 69, 144113 (2004).

J.B. Liu, D.D. Johnson, and A.V. Smirnov, Acta Mater. 53, 3601 (2005).

S. Xu, L. Xiong, Q. Deng, and D.L. McDowell, Int. J. Solids Struct. 90, 144 (2016).

S. Xu (Ph.D. Dissertation, Georgia Institute of Technology, Atlanta, GA, USA, 2016)

W. Schroeder, K. Martin, and B. Lorensen, The Visualization Toolkit: An Object Oriented Approach to 3D Graphics (Clifton Park: Kitware, 2003).

A. Stukowski, Model. Simul. Mater. Sci. Eng. 18, 015012 (2010).

A. Stukowski, Model. Simul. Mater. Sci. Eng. 20, 045021 (2012).

A. Stukowski, V.V. Bulatov, and A. Arsenlis, Model. Simul. Mater. Sci. Eng. 20, 085007 (2012).

J. Towns, T. Cockerill, M. Dahan, I. Foster, K. Gaither, A. Grimshaw, V. Hazlewood, S. Lathrop, D. Lifka, G.D. Peterson, R. Roskies, J.R. Scott, and N. Wilkins-Diehr, Comput. Sci. Eng. 16, 62 (2014).

J.R. Rice, J. Mech. Phys. Solids 40, 239 (1992).

S. Kibey, J.B. Liu, D.D. Johnson, and H. Sehitoglu, Acta Mater. 55, 6843 (2007).

M.P. Dewald and W.A. Curtin, Model. Simul. Mater. Sci. Eng. 15, S193 (2007).

B.J. Pestman, JThM de Hosson, V. Vitek, and F.W. Schapink, Scr. Metall. 23, 1431 (1989).

L. Priester, S. Poulat, B. Décamps, and J. Thibault, Mat. Res. Soc. Symp. Proc. 652, 1 (2001).

L.C. Lim and R. Raj, Acta Metall. 33, 1577 (1985).

Acknowledgements

These results are based upon work supported by the National Science Foundation as a collaborative effort between Georgia Tech (CMMI-1232878) and University of Florida (CMMI-1233113). Any opinions, findings, and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation. LX acknowledges the support from the Department of Energy, Office of Basic Energy Sciences under Award Number DE-SC0006539. The work of LX was also supported in part by the National Science Foundation under Award Number CMMI-1536925. The authors thank Dr. Dengke Chen and Dr. Benjamin Szajewski for helpful discussions, Dr. Stephen M. Foiles for providing the tabulated Foiles-EAM potential file, and Dr. Alexander Stukowski for providing the dislocation extraction algorithm code. This work used the Extreme Science and Engineering Discovery Environment (XSEDE), which is supported by National Science Foundation Grant Number ACI-1053575.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xu, S., Xiong, L., Chen, Y. et al. Comparing EAM Potentials to Model Slip Transfer of Sequential Mixed Character Dislocations Across Two Symmetric Tilt Grain Boundaries in Ni. JOM 69, 814–821 (2017). https://doi.org/10.1007/s11837-017-2302-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2302-1