Abstract

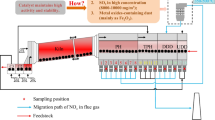

Flue gas recirculation (FGR) has been implemented for exhaust gas emissions reduction in iron ore sintering. However, the mechanism of NO x reduction through FGR is still unclear. In this paper, the laboratory pot-grate sintering test showed a 30% reduction in gas flow and 15.51% reduction in NO x emissions achieved with a 30% FGR ratio, and the sinter indexes almost matched those of the conventional process. In the sinter zone, NO-CO catalytic reduction occurs in the range of 500–900°C. When the sinter temperature is 700°C, the highest nitrogen reduction ratio (NRR) achieved is 8%; however, the NO x reduction is inhibited as the post-combustion of CO starts when the temperature increases beyond 700°C. NO x in the flue gas is mainly a product of the fuel combustion in the combustion zone, as the nitrogen conversion rate reaches 50–60%, because the N-containing intermediates exist during the fuel combustion. The existence of NO in the FGR gas inhibits the NO x generation from the fuel combustion, and the NO elimination—through the NO-carbon reaction—is significant in the combustion zone. The NRR in the combustion zone reaches a range of 18–20%.

Similar content being viewed by others

References

Y. Chen, Z. Guo, and Z. Wang, ISIJ Int. 48, 1517 (2008).

T.Y. Zhu, Technology of Sintering Flue Gas Cleaning (Beijing: Chemical Industry Press, 2009), pp. 1–5.

L.L. Fang (Master Thesis, Shandong University, Jinan, Shandong Province, 2007), pp. 13–14.

Y.G. Chen, Z. Wang, and Z.C. Guo, Acta Sci. Circumst. 28, 1720 (2008).

C.L. Mo, C.S. Teo, I. Hamilton, and J. Morrison, ISIJ Int. 37, 350 (1997).

C.G. Jin, H.G. Su, and L.J. Nam, SO x and NO x reducing method of sintering discharging gas. Korean Patent, Appl. 20000070570 (2002).

K. Morioka, S. Inaba, M. Shimizu, K. Ano, and T. Sugiyama, ISIJ Int. 40, 280 (2000).

X.G. Bi, J.Y. Liao, W. Xiong, G.F. Zhou, and Z.H. Feng, J. Wuhan Univ. Sci. Technol. 31, 449 (2008).

Y.G. Chen, Z. Wang, and Z.C. Guo, Acta Sci. Circumst. 28, 1727 (2008).

M. Gan (Ph.D. Dissertation, Central South University, Changsha, Hunan Province, 2012), pp. 12–15.

T. Terris and B. Hsiaotao, Environ. Sci. Technol. 43, 5049 (2009).

S. Roudier, L.D. Sancho, R. Remus, and M. Aguadomonsonet, JRC-IPTS Working Papers (Luxembourg: Publications Office of the European Union, 2013).

S. Ikehara, Y. Terada, S. Kubo, and J. Sakuragi, Nippon Steel Technical Report, Japan, 70, 55 (1996).

N. Menad, H. Tayibi, F.G. Carcedo, and A. Hernández, J. Clean. Prod. 14, 740 (2006).

X.H. Fan, Z.Y. Yu, M. Gan, W.Q. Li, and Z.Y. Ji, J. Iron Steel Res. Int. 20, 1 (2013).

X. Fan, Z. Yu, M. Gan, X. Chen, T. Jiang, and H. Wen, ISIJ Int. 54, 2541 (2014).

Acknowledgements

This research was financially supported by the outstanding and creative doctor scholarship of Central South University (Grant No. 2013bjjxj015), the 2014 Hunan Provincial Innovation Foundation for Postgraduate (Grant No. CX2014B094) and National Natural Science Foundation of China (Grant No. 51474237).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yu, Z., Fan, X., Gan, M. et al. NO x Reduction in the Iron Ore Sintering Process with Flue Gas Recirculation. JOM 69, 1570–1574 (2017). https://doi.org/10.1007/s11837-017-2268-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2268-z