Abstract

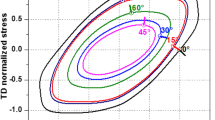

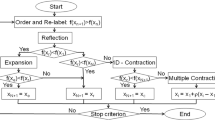

The formability of sheet metals is associated with their planar anisotropy, and finite element simulations have been applied to the sheet metal-forming process by describing the anisotropic behaviors using yield functions and hardening models. In this study, the evaluation of anisotropic constitutive models was performed based on the non-uniform height profile or earing in circular cylindrical cup drawing. Two yield functions, a quadratic Hill1948 and a non-quadratic Yld2000-2d model, were used under non-associated and associated flow rules, respectively, to simultaneously capture directional differences in yield stress and r value. The effect of the evolution of anisotropy on the earing prediction was also investigated by employing simplified equivalent plastic strain rate-dependent anisotropic coefficients. The computational results were in good agreement with experiments when the proper choice of the yield function and flow rule, which predicts the planar anisotropy, was made. Moreover, the accuracy of the earing profile could be significantly enhanced if the evolution of anisotropy between uniaxial and biaxial stress states was additionally considered.

Similar content being viewed by others

References

R. Hill, Proc. R. Soc. Lond. 193A, 281 (1948).

F. Barlat, J.C. Brem, J.W. Yoon, K. Chung, R.E. Dick, D.J. Rege, F. Pourboghrat, S.H. Choi, and E. Chu, Int. J. Plast. 19, 1297 (2003).

T.B. Stoughton, Int. J. Plast. 18, 687 (2002).

T. Park and K. Chung, Int. J. Solids Struct. 25, 3582 (2012).

J.Y. Lee, F. Barlat, and M.G. Lee, Int. J. Plast. 71, 113 (2015).

J. Choi, J.W. Lee, G.H. Bae, F. Barlat, and M.G. Lee, JOM 68, 1850 (2016).

J.W. Lee, J.J. Ha, H.J. Bong, D. Kim, and M.G. Lee, Mater. Sci. Eng. A 672, 65 (2016).

J.W. Yoon, F. Barlat, K. Chung, F. Pourboghrat, and D.Y. Yang, J. Mater. Process. Technol. 80–81, 433 (1998).

T.B. Stoughton and J.W. Yoon, Int. J. Plast. 25, 1777 (2009).

J.Y. Lee, L. Xue, F. Barlat, R.H. Wagoner, and M.G. Lee, Exp. Mech. 53, 1681 (2013).

F. Barlat, S. Panchanadeeswaran, and O. Richmond, Metall. Mater. Trans. A 22, 1525 (1991).

Acknowledgements

All authors appreciate the support from POSCO. MGL appreciates partial supports by the National Research Foundation of Korea (NRF) Grant funded by Korean government (NRF-2012R1A5A1048294) and (NRF-2014R1A2A2A11052889).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Choi, H.J., Lee, K.J., Choi, Y. et al. Effect of Evolutionary Anisotropy on Earing Prediction in Cylindrical Cup Drawing. JOM 69, 915–921 (2017). https://doi.org/10.1007/s11837-016-2241-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-2241-2