Abstract

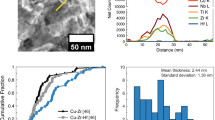

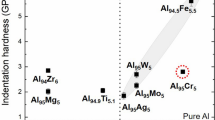

Nanocrystalline Cu-3 at.% Zr powders with ~20 nm average grain size were created with mechanical alloying and their thermal stability was studied from 550–950°C. Annealing drove Zr segregation to the grain boundaries, which led to the formation of amorphous intergranular complexions at higher temperatures. Grain growth was retarded significantly, with 1 week of annealing at 950°C, or 98% of the solidus temperature, only leading to coarsening of the average grain size to 54 nm. The enhanced thermal stability can be connected to both a reduction in grain boundary energy with doping as well as the precipitation of ZrC particles. High mechanical strength is retained even after these aggressive heat treatments, showing that complexion engineering may be a viable path toward the fabrication of bulk nanostructured materials with excellent properties.

Similar content being viewed by others

References

M.A. Meyers, A. Mishra, and D.J. Benson, Prog. Mater Sci. 51, 427 (2006).

K.S. Kumar, H. Van Swygenhoven, and S. Suresh, Acta Mater. 51, 5743 (2003).

Y.T. Zhu, X.Z. Liao, and X.L. Wu, Prog. Mater. Sci. 57, 1 (2012).

M.A. Tschopp, H.A. Murdoch, L.J. Kecskes, and K.A. Darling, JOM 66, 1000 (2014).

H.Q. Li, H. Choo, Y. Ren, T.A. Saleh, U. Lienert, P.K. Liaw, and F. Ebrahimi, Phys. Rev. Lett. 101, 015502 (2008).

H.A. Padilla and B.L. Boyce, Exp. Mech. 50, 5 (2010).

T.J. Rupert and C.A. Schuh, Acta Mater. 58, 4137 (2010).

L. Liu, Y. Li, and F. Wang, J. Mater. Sci. Technol. 26, 1 (2010).

C. Suryanarayana and C.C. Koch, Hyperfine Interact. 130, 5 (2000).

P.G. Sanders, J.A. Eastman, and J.R. Weertman, Acta Mater. 45, 4019 (1997).

J.A. Sharon, H.A.I. Padilla, and B.L. Boyce, J. Mater. Res. 28, 1539 (2013).

K.A. Darling, B.K. VanLeeuwen, C.C. Koch, and R.O. Scattergood, Mater. Sci. Eng. A 527, 3572 (2010).

R.A. Andrievski, J. Mater. Sci. 49, 1449 (2014).

K. Pantleon and M.A.J. Somers, Mater. Sci. Eng. A 528, 65 (2010).

T. Chookajorn, H.A. Murdoch, and C.A. Schuh, Science 337, 951 (2012).

C. Suryanarayana and N. Al-Aqeeli, Prog. Mater. Sci. 58, 383 (2013).

C.C. Koch, R.O. Scattergood, K.A. Darling, and J.E. Semones, J. Mater. Sci. 43, 7264 (2008).

A.J. Detor and C.A. Schuh, Acta Mater. 55, 371 (2007).

F. Zhou, J. Lee, and E.J. Lavernia, Scripta Mater. 44, 2013 (2001).

J. Weissmuller, Nanostruct. Mater. 3, 261 (1993).

J. Weissmuller, J. Mater. Res. 9, 4 (1994).

H.A. Murdoch and C.A. Schuh, J. Mater. Res. 28, 2154 (2013).

H. Bakker, Enthalpies in Alloys: Miedema’s Semi-Empirical Model (Zurich: Trans Tech Publications, 1998), p. 1–92.

M. Zhu, Z.F. Wu, M.Q. Zeng, L.Z. Ouyang, and Y. Gao, J. Mater. Sci. 43, 3259 (2008).

K.A. Darling, M.A. Tschopp, B.K. VanLeeuwen, M.A. Atwater, and Z.K. Liu, Comput. Mater. Sci. 84, 255 (2014).

P.R. Cantwell, M. Tang, S.J. Dillon, J. Luo, G.S. Rohrer, and M.P. Harmer, Acta Mater. 62, 1 (2014).

E.W. Hart, Scripta Metall. 2, 179 (1968).

D.R. Clarke and G. Thomas, J. Am. Ceram. Soc. 60, 491 (1977).

S.J. Dillon, M.P. Harmer, and J. Luo, JOM 61, 38 (2009).

L.K.V. Lou, T.E. Mitchell, and A.H. Heuer, J. Am. Ceram. Soc. 61, 392 (1978).

O.A. Kogtenkova, S.G. Protasova, A.A. Mazilkin, B.B. Straumal, P. Zieba, T. Czeppe, and B. Baretzky, J. Mater. Sci. 47, 8367 (2012).

E. Jud, Z. Zhang, W. Sigle, and L.J. Gauckler, J. Electroceram. 16, 191 (2006).

S. Bhattacharyya, A. Subramaniam, C.T. Koch, R.M. Cannon, and M. Ruhle, Mater. Sci. Eng. A 422, 92 (2006).

G.B. Winkelman, C. Dwyer, T.S. Hudson, D. Nguyen-Manh, M. Doblinger, R.L. Satet, M.J. Hoffmann, and D.J.H. Cockayne, Appl. Phys. Lett. 87, 061911 (2005).

S.Y. Choi, D.Y. Yoon, and S.J.L. Kang, Acta Mater. 52, 3721 (2004).

S.L. Ma, K.M. Asl, C. Tansarawiput, P.R. Cantwell, M.H. Qi, M.P. Harmer, and J. Luo, Scripta Mater. 66, 203 (2012).

D. Raabe, M. Herbig, S. Sandlobes, Y. Li, D. Tytko, M. Kuzmina, D. Ponge, and P.P. Choi, Curr. Opin. Solid State Mater. Sci. 18, 253 (2014).

M. Tang, W.C. Carter, and R.M. Cannon, J. Mater. Sci. 41, 7691 (2006).

S.J. Dillon, M. Tang, W.C. Carter, and M.P. Harmer, Acta Mater. 55, 6208 (2007).

A. Kundu, K.M. Asl, J. Luo, and M.P. Harmer, Scripta Mater. 68, 146 (2013).

J. Luo, H.K. Cheng, K.M. Asl, C.J. Kiely, and M.P. Harmer, Science 333, 1730 (2011).

W. Sigle, G. Richter, M. Ruhle, and S. Schmidt, Appl. Phys. Lett. 89, 121911 (2006).

Z.L. Pan and T.J. Rupert, Comput. Mater. Sci. 93, 206 (2014).

Z.L. Pan and T.J. Rupert, Acta Mater. 89, 205 (2015).

J. Chen, L. Lu, and K. Lu, Scripta Mater. 54, 1913 (2006).

Y.M. Wang, J. Li, A.V. Hamza, and T.W. Barbee, Proc. Natl. Acad. Sci. USA 104, 11155 (2007).

D. Wang, Y. Li, B.B. Sun, M.L. Sui, K. Lu, and E. Ma, Appl. Phys. Lett. 84, 4029 (2004).

Y. Li, Q. Guo, J.A. Kalb, and C.V. Thompson, Science 322, 1816 (2008).

Z. Zhang, F. Zhou, and E.J. Lavernia, Metall. Mater. Trans. A 34A, 1349 (2003).

C.E. Krill and R. Birringer, Philos. Mag. A 77, 621 (1998).

I. MacLaren, Ultramicroscopy 99, 103 (2004).

A.J. Detor, M.K. Miller, and C.A. Schuh, Philos. Mag. Lett. 87, 581 (2007).

J.Y. Xiang, S.C. Liu, W.T. Hu, Y. Zhang, C.K. Chen, P. Wang, J.L. He, D.L. Yu, B. Xu, Y.F. Lu, Y.J. Tian, and Z.Y. Liu, J. Eur. Ceram. Soc. 31, 1491 (2011).

A.S. Khan, B. Farrokh, and L. Takacs, J. Mater. Sci. 43, 3305 (2008).

A.S. Khan, H.Y. Zhang, and L. Takacs, Int. J. Plast. 16, 1459 (2000).

M.A. Atwater, R.O. Scattergood, and C.C. Koch, Mater. Sci. Eng. A 559, 250 (2013).

P.C. Millett, R.P. Selvam, and A. Saxena, Acta Mater. 55, 2329 (2007).

L. Pauling, J. Am. Chem. Soc. 69, 542 (1947).

D.G. Morris and M.A. Morris, Acta Metall. Mater. 39, 1763 (1991).

T. Frolov, K.A. Darling, L.J. Kecskes, and Y. Mishin, Acta Mater. 60, 2158 (2012).

W. Xu, L. Li, M. Saber, C. Koch, Y. Zhu, and R. Scattergood, Metall. Mater. Trans. A 46, 4394 (2015).

S.J. Dillon and M.P. Harmer, J. Am. Ceram. Soc. 91, 2304 (2008).

S.J. Dillon and M.P. Harmer, J. Am. Ceram. Soc. 91, 2314 (2008).

M.P. Harmer, Science 332, 182 (2011).

J. Luo, Appl. Phys. Lett. 95, 071911 (2009).

G. Duscher, M.F. Chisholm, U. Alber, and M. Ruhle, Nat. Mater. 3, 621 (2004).

D. Arias and J.P. Abriata, Bull. Alloy Phase Diagr. 11, 452 (1990).

J. Luo, Crit. Rev. Solid State 32, 67 (2007).

J. Luo, Curr. Opin. Solid State Mater. Sci. 12, 81 (2008).

N.X. Zhou and J. Luo, Acta Mater. 91, 202 (2015).

M.A. Atwater, H. Bahmanpour, R.O. Scattergood, and C.C. Koch, J. Mater. Sci. 48, 220 (2013).

T.J. Rupert, J.C. Trenkle, and C.A. Schuh, Acta Mater. 59, 1619 (2011).

Z. Zhang and D.L. Chen, Scripta Mater. 54, 1321 (2006).

D. Tabor, J. Inst. Met. 79, 1 (1951).

N.Q. Vo, J. Schafer, R.S. Averback, K. Albe, Y. Ashkenazy, and P. Bellon, Scripta Mater. 65, 660 (2011).

R.K. Rajgarhia, D.E. Spearot, and A. Saxena, J. Mater. Res. 25, 411 (2010).

S. Ozerinc, K.P. Tai, N.Q. Vo, P. Bellon, R.S. Averback, and W.P. King, Scripta Mater. 67, 720 (2012).

T.J. Rupert, J.R. Trelewicz, and C.A. Schuh, J. Mater. Res. 27, 1285 (2012).

C. Brandl, T.C. Germann, and A. Misra, Acta Mater. 61, 3600 (2013).

C. Gammer, C. Mangler, C. Rentenberger, and H.P. Karnthaler, Scripta Mater. 63, 312 (2010).

Acknowledgements

This study was supported by the U.S. Army Research Office under Grant W911NF-12-1-0511. Materials characterization was performed at the Laboratory for Electron and X-ray Instrumentation (LEXI) at UC Irvine, using instrumentation funded in part by the National Science Foundation Center for Chemistry at the Space–Time Limit (CHE-082913).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khalajhedayati, A., Rupert, T.J. High-Temperature Stability and Grain Boundary Complexion Formation in a Nanocrystalline Cu-Zr Alloy. JOM 67, 2788–2801 (2015). https://doi.org/10.1007/s11837-015-1644-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1644-9