Abstract

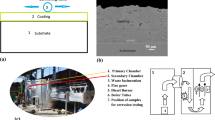

The surface behavior of the Ni-based superalloy (composition similar to UNS N06075) is altered in this study by depositing a 298-µm-thick coating for various erosive-corrosive and wear applications at a high temperature. The 50%Ni-50%Cr coating was developed by a high-pressure cold-spraying method. The coating microstructure was studied by various characterization techniques. The unmelted solid particles formed the coating structure, which is homogeneous, dense, hard, and free from cracks, oxides, and other defects. The coating composition and microstructure is suitable for providing protection to the substrate under high-temperature corrosive conditions. The developed coating performed well, with degradation rate of 0.47 mm/year, in the chlorine-based highly corrosive conditions of actual waste incinerator at 900°C.

Similar content being viewed by others

References

R.K. Singh Raman and A. Tiwari, JOM 66, 637 (2014).

F. Wang and M. Zhao, Mater. Manuf. Proc. (2014). doi:10.1080/10426914.2014.952042.

M. Jeandin, G. Rolland, L.L. Descurninges, and M.H. Berger, Surf. Eng. 30, 291 (2014).

Y. Gao, M.C. Chen, and C.X. Shi, Mater. Manuf. Proc. 14, 691 (1999).

M.D. Trexler, R. Carter, W.S. de Rosset, D. Gray, D.J. Helfritch, and V.K. Champagne, Mater. Manuf. Proc. 27, 820 (2012).

D.E. Wolfe, T.J. Eden, J.K. Potter, and A.P. Jaroh, J. Therm. Spray Technol. 15, 400 (2006).

C. Lee and J. Kim, J. Therm. Spray Technol. 24, 592 (2015).

F. Gärtner, T. Stoltenhoff, T. Schmidt, and H. Kreye, J. Therm. Spray Technol. 15, 223 (2006).

T.H. Van Steenkiste, J.R. Smith, R.E. Teets, J.J. Moleski, D.W. Gorkiewicz, R.P. Tison, D.R. Marantz, K.A. Kowalsky, W.L. Riggs, P.H. Zajchowski, B. Pilsner, R.C. McCune, and K.J. Barnett, Surf. Coat. Technol. 111, 62 (1999).

P. Fauchais, G. Montavon, and G. Bertrand, J. Therm. Spray Technol. 19, 56 (2010).

Y. Liu, P. Samimi, I. Ghamarian, D.A. Brice, D.E. Huber, Z. Wang, V. Dixit, S. Koduri, H.L. Fraser, and P.C. Collins, JOM 67, 164 (2015).

A.E. Segall, A.N. Papyrin, J.C. Conway Jr, and D. Shapiro, JOM 50, 52 (1998).

N. Kaur, M. Kumar, S.K. Sharma, D.Y. Kim, S. Kumar, N.M. Chavan, S.V. Joshi, N. Singh, and H. Singh, Appl. Surf. Sci. 328, 13 (2015).

L. Gillibert, C. Peyrega, D. Jeulin, V. Guipont, and M. Jeandin, J. Microsc. 248, 187 (2012).

V. Guipont, M. Jeandin, G. Rolland, D. Jeulin, C. Peyrega, and W. Ludwig, Therm. Spray Bull. 3, 140 (2010).

D.K. Christoulis, S. Guetta, E. Irissou, V. Guipont, M.H. Berger, M. Jeandin, J.-G. Legoux, C. Moreau, S. Costil, M. Boustie, Y. Ichikawa, and K. Ogawa, J. Therm. Spray Technol. 19, 1062 (2010).

G. Rolland, P. Sallamand, V. Guipont, M. Jeandin, E. Boller, and C. Bourda, J. Therm. Spray Technol. 21, 758 (2012).

E. Irissou, J.G. Legoux, A.N. Ryabinin, B. Jodoin, and M. Christian, J. Therm. Spray Technol. 17, 495 (2008).

R. Ghelichi and M. Guagliano, Frattura ed Integrità Strutt. 8, 30 (2009).

C.-J. Li, W.-Y. Li, and H. Lio, J. Therm. Spray Technol. 15, 212 (2006).

M.A. Uusitalo, P.M.J. Vuoristo, and T.A. Mantyla, Mater. Sci. Eng. 346, 168 (2003).

R.A. Antunes and M.C. Lopes de Oliveira, Corros. Sci. 76, 6 (2013).

G. Chen, N. Zhang, W. Maa, V.S. Rotter, and Y. Wang, Fuel 140, 317 (2015).

S. Karlsson, L.-E. Åmand, and J. Liske, Fuel 139, 482 (2015).

J. Lehmusto, B.-J. Skrifvars, P. Yrjas, and M. Hupa, Corros. Sci. 53, 3315 (2011).

A. Phongphiphat, C. Ryu, Y.B. Yang, K.N. Finney, A. Leyland, V.N. Sharifi, and J. Swithenbank, Corros. Sci. 52, 3861 (2010).

A. Ruh and M. Spiegel, Corros. Sci. 48, 679 (2006).

F. Goutier, S. Valette, A. Vardelle, and P. Lefort, Surf. Coat. Technol. 205, 4425 (2011).

A. Zahs, M. Spiegel, and H.-J. Grabke, Corros. Sci. 42, 1093 (2000).

Y. Kawahara, Corros. Sci. 44, 223 (2002).

G. Sorell, Mater. High Temp. 14, 137 (1997).

Y. Kawahara, J. Therm. Spray Technol. 16, 202 (2007).

Acknowledgement

Author thankfully acknowledge the research grant under UGC Minor Project from UGC, New Delhi, Govt. of India, for carrying out this R&D work on “Studies on the behavior of coatings in improving the resistance to hot corrosion degradation in waste incineration environment,” vide F. No. 39-1003/2010(SR).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, H. Fabrication of High-Pressure Cold-Sprayed Coating on Ni-Based Superalloy for High-Temperature Corrosive Conditions. JOM 67, 2564–2572 (2015). https://doi.org/10.1007/s11837-015-1628-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1628-9