Abstract

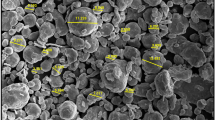

The butt joining of Inconel 718 plates at 981°C solution treated and aged (981STA) condition was carried out using the microwave hybrid heating technique with Inconel 718 powder as a filler material. The developed joints were free from any microfissures (cracks) and were metallurgically bonded through complete melting of the powder particles. The as-welded joints were subjected to postweld heat treatments, including direct-aged, 981STA and 1080STA. The microstructural features of the welded joints were investigated using a field emission-scanning electron microscope equipped with x-ray elemental analysis. Microhardness and room-temperature tensile properties of the welded joints were evaluated. The postweld heat-treated specimens exhibited higher microhardness and tensile strength than the as-welded specimens due to the formation of strengthening precipitates in the microstructure after postweld heat treatments. The microhardness of the fusion zone of the joint in 1080STA condition was higher than all welded conditions due to the complete dissolution of Laves phase after 1080STA treatment. However, the tensile strength of the welded specimen in 981STA condition was higher than all welded conditions. The tensile strength in 1080STA condition was lower than that in 981STA condition because of the grain coarsening that took place after 1080STA condition. The fractography of the fractured surfaces was carried out to determine the structure–property–fracture correlation.

Similar content being viewed by others

References

A. Lingenfelte, Welding of Inconel 718—A Historical Review 1989, ed. E.A. Loria (Warrendale, PA: TMS, 1989), pp. 673–683.

S. Kou, Welding Metallurgy, 2nd ed. (Hoboken, NJ: Wiley, 2003), pp. 375–392.

G.D.J. Ram, A.V. Reddy, K.P. Rao, and G.M. Reddy, Mater. Sci. Technol. 21, 1132 (2005).

C. Slama, and M. Abdellaoui, J. Alloy. Compd. 306, 277 (2000).

D.F. Paulonis, J.M. Oblak, and D.S. Duvall, Trans. ASM 62, 611 (1969).

G.D.J. Ram, A.V. Reddy, K.P. Rao, and G.M. Reddy, Sci. Technol. Weld. Join. 9, 390 (2004).

N.L. Richards, X. Huang, and M.C. Chaturvedi, Mater. Charact. 28, 179 (1992).

C.H. Radhakrishna and K.P. Rao, Mater. High Temp. 12, 323 (1994).

C.H. Radhakrishna and K.P. Rao, J. Mater. Sci. 32, 1977 (1997).

X. Cao, B. Rivaux, M. Jahazi, J. Cuddy, and A. Birur, J. Mater. Sci. 44, 4557 (2009).

G.D.J. Ram, A.V. Reddy, K.P. Rao, G.M. Reddy, and J.K.S. Sundar, J. Mater. Process. Technol. 167, 73 (2005).

S. Gobbi, L. Zhang, J. Norris, K.H. Richter, and J.H. Loreau, J. Mater. Process. Technol. 56, 333 (1996).

W.H. Suttan, Am. Ceram. Soc. Bull. 168, 376 (1989).

D. Gupta and A.K. Sharma, Surf. Coat. Technol. 205, 5147 (2011).

R. Roy, D. Agrawal, J. Cheng, and S. Gedevanishvili, Nature 399, 668 (1999).

A.K. Sharma, M.S. Srinath, and P. Kumar, Indian patent 1994/Del/2009 (2009).

M.S. Srinath, A.K. Sharma, and P. Kumar, J. Manuf. Process. 13, 141 (2011).

M.S. Srinath, A.K. Sharma, and P. Kumar, Mater. Des. 32, 2685 (2011).

M.S. Srinath, A.K. Sharma, and P. Kumar, Proc. Inst. Mech. Eng. B J. Eng. Manuf. 225, 1083 (2011).

R. Vincent, Acta Metall. 33, 1205 (1985).

Acknowledgement

The authors would like to express gratefulness to the Board of Research of Nuclear Sciences (BRNS) India for financing this work with Project No. 2010/36/60-BRNS/2048.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bansal, A., Sharma, A.K., Kumar, P. et al. Structure–Property Correlations in Microwave Joining of Inconel 718. JOM 67, 2087–2098 (2015). https://doi.org/10.1007/s11837-015-1523-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1523-4