Abstract

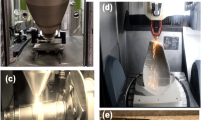

Aerospace and automotive industries provide the next big opportunities for additive manufacturing. Currently, the additive industry is confronted with four major challenges that have been identified in this article. These challenges need to be addressed for the additive technologies to march into new frontiers and create additional markets. Specific potential success in the transportation sectors is dependent on the ability to manufacture complicated structures with high performance. Most of the techniques used for metal-based additive manufacturing are fusion based because of their ability to fulfill the computer-aided design to component vision. Although these techniques aid in fabrication of complex shapes, achieving high structural performance is a key problem due to the liquid–solid phase transformation. In this article, friction stir additive manufacturing (FSAM) is shown as a potential solid-state process for attaining high-performance lightweight alloys for simpler geometrical applications. To illustrate FSAM as a high-performance route, manufactured builds of Mg-4Y-3Nd and AA5083 are shown as examples. In the Mg-based alloy, an average hardness of 120 HV was achieved in the built structure and was significantly higher than that of the base material (97 HV). Similarly for the Al-based alloy, compared with the base hardness of 88 HV, the average built hardness was 104 HV. A potential application of FSAM is illustrated by taking an example of a simple stiffener assembly.

Similar content being viewed by others

References

Ideas lab staff, “Aviation Proves Newest Territory for 3D Printing” (16 July 2014), http://www.ideaslaboratory.com/post/93343746148/aviation-proves-newest-territory-for-3d-printing

E. Brandl, B. Baufeld, C. Leyens, and R. Gault, Phys. Proc. 5, 595 (2010).

K.M.B. Taminger and R.A. Hafley (Paper Presented at the Proceedings of the 3rd Annual Auomotive Composites Conference, 2003), pp. 1–6

Y.N. Zhang, X. Cao, P. Wanjara, and M. Medraj, Mater. Res. Soc. 29, 2006 (2014).

L. Facchini, E. Magalini, P. Robotti, A. Molinari, S. Höges, and K. Wissenbach, Rapid Prototype J. 16, 450 (2010).

ASM Handbook, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, vol. 2, 10th edn. (ASM International, Materials Park, OH, 1990), pp. 62–122

D.E. Schick, R.M. Hahnlen, R. Dehoff, P. Collins, S.S. Babu, M.J. Dapino, and J.C. Lippold, Welding J. 89, 105 (2010).

S. Biamino, A. Penna, U. Ackelid, S. Sabbadini, O. Tassa, P. Fino, M. Pavese, P. Gennaro, and C. Badini, Intermetallics 19, 776 (2010).

X. Zhang, J. Chen, X. Lin, and W. Huang, Mater. Sci. Eng. A 478, 119 (2010).

R.R. Dehoff and S.S. Babu, Acta Mater. 58, 4305 (2010).

P.H. Lequeu, R. Muzzolini, J.C. Ehrstrom, F. Bron, and R. Maziarz (Slide Presentation at the Aeromat Conference, Seattle, WA, May 2006)

J.A. Baumann, Technical Report: Production of Energy Efficient Preform Structures (Huntington Beach, CA: The Boeing Company, 2012).

S. Palanivel, N. Phalgun, B. Glass, and R.S. Mishra, Mater. Des. 65, 934 (2015).

R.S. Mishra and Z.Y. Ma, Mater. Sci. Eng. R 50, 1 (2005).

Acknowledgements

The authors would like to thank Mr. Rick DeLorme and Dr. Bruce Davis of Magnesium Elektron, Inc. NA for providing the WE43 alloy sheets.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Palanivel, S., Sidhar, H. & Mishra, R.S. Friction Stir Additive Manufacturing: Route to High Structural Performance. JOM 67, 616–621 (2015). https://doi.org/10.1007/s11837-014-1271-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-1271-x