Abstract

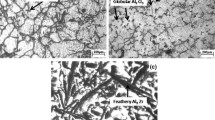

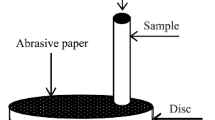

The wear behavior of a weight fraction of particles with up to 30 wt.% in situ AlB2 flakes reinforced in Al-4Cu matrix alloy composites and fabricated by a squeeze casting method was investigated in a pin-on-disk abrasion test instrument against different SiC abrasives at room conditions. Wear tests were performed under the load of 10 N against SiC abrasive papers of 80, 100, and 120 mesh grits. The effects of sliding speed, AlB2 flake content, and abrasive grit sizes on the abrasive wear properties of the matrix alloy and composites have been evaluated. The main wear mechanisms were identified using an optical microscope. The results showed that in situ AlB2 flake reinforcement improved the abrasion resistance against all the abrasives used, and the abrasive wear resistance decreased with an increase in the sliding speed and the abrasive grit size. The wear resistances of the composites were considerably bigger than those of the matrix alloy and increased with increases in in situ AlB2 flake contents.

Similar content being viewed by others

References

J.M. Torralba, C.E. Da Costa, and F. Velasco, Mater. Process. Technol. 133, 203 (2003).

K. Sivaprasad, S.P. Kumaresh Babu, S. Natarajan, R. Narayanasamy, B. Anil Kumar, and G. Dinesh, Mater. Sci. Eng. A 498, 495 (2008).

L. Lei, L. Weiwei, T. Yiping, S. Bin, and H. Wenbin, Wear 266, 733 (2009).

D. Mandal, B.K. Dutta, and S.C. Panigrahi, J. Mater. Sci. 42, 2417 (2007).

S. Das, S. Das, and K. Das, Compos. Sci. Technol. 67, 746 (2007).

D. Jun, L. Yao-Hui, Y. Si-Rong, and L. Wen-Fang, Wear 257, 930 (2004).

S.C. Tjong and Z.Y. Ma, Mater. Sci. Eng. 29, 49 (2000).

A.P. Sannino and H.J. Rack, Wear 189, 1 (1995).

R.L. Deuis, C. Subramanian, and J.M. Yellup, Wear 201, 132 (1996).

H. Oh, S. Lee, J. Jung, and S. Ahn, Metall. Mater. Trans. A 32, 515 (2001).

S. Das, D.P. Mondal, and G. Dixit, Metall. Mater. Trans. A 32, 633 (2001).

K.H. Zum Gahr, Metal. Prog. 116, 46 (1979).

K.H. ZumGahr, Zeitsc Fur Metall. 69, 312 (1978).

I.M. Hutchings, Chem. Eng. Sci. 42, 869 (1987).

I.M. Hutching, Proceedings of the Conference of Advanced Materials and Processes, (Cambridge, UK: University of Cambridge, 1991), p. 56.

O. Yilmaz and S. Buytoz, Compos. Sci. Technol. 61, 2381 (2001).

Z.F. Zhang, L.C. Zhang, and Y.W. Mai, J. Mater. Sci. 30, 1961 (1995).

S. Chung and B.H. Hwang, Tribol. Int. 27, 307 (1994).

H. Ahlatci, E. Candan, and H. Çimenoğlu, Zeitsc Fur Metall. 93, 330 (2002).

S. Usmani, S. Sampath, D.L. Houck, and D. Lee, Tribol. Trans. 40, 470 (1997).

E. Candan, H. Ahlatci, and H. Cimenoglu, Wear 247, 133 (2001).

T.A. Stolarski, E. Jisheng, D.T. Gawne, and S. Panesar, Ceram. Int. 21, 355 (1995).

D.P. Mondal, S. Das, A.K. Jha, and A.H. Yegneswaran, Wear 223, 131 (1998).

D. Forrest, K. Matsuoka, M. Tse, and E. Rabinowicz, Wear 162–164, 126 (1993).

J. Larsen-Badse, Wear 11, 213 (1968).

E. Rabinowicz and A. Mutis, Wear 8, 381 (1965).

N. Axen and K.H. Zum Gahr, Wear 157, 189 (1992).

Y. Sahin, Mater. Des. 24, 95 (2003).

H.L. Lee, W.H. Lu, and S.L. Chan, Wear 159, 223 (1992).

N. Axen, A. Alahelisten, and S. Jacobson, Wear 173, 95 (1994).

E.A. Diler and R. Ipek, Mater. Sci. Eng. 548, 43 (2012).

E.A. Diler and R. Ipek, Compos. Part B: Eng. 50, 371 (2013).

S. Das, D.P. Mondal, S. Sawla, and N. Ramakrishnan, Wear 264, 47 (2008).

O. Savas, R. Kayikci, and S. Koksal, Adv. Compos. Lett. 21, 44 (2012).

Ö. Savaş and R. Kayikci, J. Alloy. Compd. 580, 232 (2013).

V.V. Ganesh, C.K. Lee, and M. Guptha, Mater. Sci. Eng. A 333, 193 (2002).

C.S. Ramesh, R. Keshavamurthy, S. Pramod, and P.G. Koppad, J. Mater. Process. Technol. 211, 1423 (2011).

M. Kök, Compos. Part A: Appl. Sci. Manuf. 37, 457 (2006).

Y. Sahin and V. Kilicli, Wear 271, 2766 (2011).

J. Hemanth, Compos. Part B: Eng. 42, 1826 (2011).

A.G. Wang and I.M. Hutching, Mater. Sci. Technol. 5, 71 (1989).

K.R. Suresh, H.B. Niranjan, P.M. Jebaraj, and M.P. Chowdiah, Wear 255, 638 (2003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ficici, F. Abrasive Wear of In Situ AlB2/Al-4Cu Composite Material Produced by Squeeze Casting Method. JOM 66, 711–719 (2014). https://doi.org/10.1007/s11837-014-0949-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-0949-4