Abstract

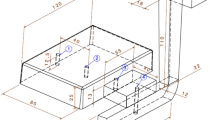

The mechanical characteristics of 6063 aluminum alloy cast in a mixture of aluminum dross and silica sand as mold have been examined. The amount of dross in the green silica sand was varied in the range of 0–80% with bentonite as binder. In all, 40 samples were cast, and 8 of these were left in the as-cast condition for control while 32 were first homogenized at 470°C for 6 h and then rolled in a two-high mill at ambient temperature to 10% reduction in one pass. The rolled samples were solution heat treated at 515°C for 8 h followed by normalizing, annealing, and quench tempering, respectively. The samples were then simulated and tensile behavior coupled with the evaluation of microhardness and microstructures developed. The results obtained demonstrate significant improvement in mechanical properties from 50% to 80% dross in the mold. Tensile strength increased to 177 MPa and 15% elongation compared with conventional 6063-T5 aluminum alloy with 145 MPa tensile strength and 8% elongation. The improvement in mechanical properties by the quench-tempered samples can be attributed to the inducement of fine and coherent Mg2Si crystals within the matrix. Furthermore, the overall analysis of the proportion of dross to the size of cast show that about 64% of dross generated can be utilized as mold material.

Similar content being viewed by others

References

H. Ghorab, A. Rizk, A. Matter, and A. Salama, Polym. Plast. Technol. Eng. 43, 1663 (2004).

J. Hwang, X. Huang, and Z. Xu, J Miner. Mater. Charact. Eng. 5, 47 (2006).

E. Kalatny, S. Halawy, M. Mohammed, and M. Zaki, J. Powder Technol. 132, 137 (2003).

Y. Huang, R. Bird, and O. Heidrich, J. Resour. Conserv. Recycl. 32, 58 (2007).

B. Luchheva, T. Tsonev, and R. Petkov, J. Chem. Tech. Met. 40, 335 (2005).

G. Kulik and J. Daley, Proceedings of the 2nd International Symposium on Recycling of Metals and Engineered Materials, ed. J.H.L. Van Linden, D.L. Stewart, and Y. Sahai (Warrendale, PA: TMS, 1990), p. 427.

E. Petavratzi, Characterisation of mineral wastes, resources and processing technologies. WRT 177/WRO 115 (2007), pp. 1–8.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Adeosun, S.O., Sekunowo, O.I., Balogun, S.A. et al. Study on the Mechanical Properties of Cast 6063 Al Alloy Using a Mixture of Aluminum Dross and Green Sand as Mold. JOM 64, 905–910 (2012). https://doi.org/10.1007/s11837-012-0389-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-012-0389-y