Abstract

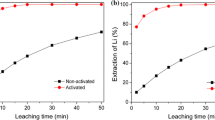

A process of purification of coal-based coke powder as anode for Li-ion batteries was attempted. The process started with the treatment of coke powder with dilute hydrofluoric acid solution, followed by united-acid-leaching using sulfuric acid and hydrochloric acid. The effects of altering the hydrofluoric acid addition, hydrofluoric acid concentration, contact time, temperature and acid type were investigated. A minimum ash content of 0.35% was obtained when proper conditions were applied. The electrochemical performance of purified coke powder shows greatly improved electrochemical performance. The as-purified coke powder presented an initial reversible capacity of 257.4 mAh/g and a retention rate of 95% after 50 cycles. The proposed purification process paves a way to prepare a promising anode material with good performance with low cost of coke powder for Li-ion batteries.

Similar content being viewed by others

References

LIU C L, LUO H M, GOU G J. The shaping technology of powdered coke [J]. Techniques and Equipment for Environmental Pollution Control, 2002 (12): 73–75.

WU Y P, RAHM E, HOLZE R. Carbon anode materials for lithium ion batteries [J]. Power Sources, 2003, 114(2): 228–236.

YOSHIO M, WANG H Y, LEE Y S, FUKUDA K. Naphthalene sulfonate formaldehyde (NSF)-resin derived carbon beads as an anode material for Li-ion batteries [J]. Electrochimica Acta, 2003, 48(7):791–797.

QIU W H, ZHOU R Q, YANG L L, LIU Q G. Lithium-ion rechargeable battery with petroleum coke anode and polyaniline cathode [J]. Solid State Ionics, 1996, 86/87/88(2): 903–906.

LIU T, LUO R Y, YOON S H, MOCHIDA I. Anode performance of boron-doped graphites prepared from shot and sponge cokes [J]. Power Sources, 2010, 195(6): 1714–1719.

MASATOSHI T, RYUJI O, KOJI U, KOJI N, TOSHIHIKO S. Lithium secondary battery. EP, 0624913 [P]. 1994-3-3.

SCHROEDER M, WINTER M, PASSERINI S, BALDUCCI A. On the use of soft carbon and propylene carbonate-based electrolytes in lithium-ion capacitors [J]. Journal of the Electrochemical Society, 2012, 159(8): A1240–A1245.

MARKEL R F, Goldberger W M. Method for heat treating carbonaceous material in a fluidized bed. US, 4160813 [P]. 1979-7-10.

ZHANG R, YU L X. Research progress on preparation and application of high purity graphite [J]. China Non-metallic Mining Industry Herald, 2006, 54(S): 59–61. (in Chinese)

QIU G Z. Processing of Mineral Materials [M]. Changsha: Central South University Press, 2003: 40–75.

SATO Y. Purification of MWNTs combining wet grinding, hydrothermal treatment, and oxidation [J]. J Phys Chem B, 2001, 105(17): 3387–3392.

ZAGHIB K, SONG X, GUERFI A, RIOUX R, KINOSHITA K. Purification process of natural graphite as anode for Li-ion batteries: Chemical versus thermal [J]. Power Sources, 2003, 119–121(1): 8–15.

AKIRA K, TAKAHIKO E. Method for highly purifying graphite. JP, 03050110 [P]. 1991-3-4.

KIM J, KIM B. Chemical and low-expansion treatments for purifying natural graphite powder [J]. Physicochemical Problems of Mineral Processing, 2007, 41: 37–49.

MAMINA L I, GILMANSHINA T R, KOROLEVA G A. Promising methods of graphite enrichment [J]. Litejnoe Proizvodstvo, 2003, 2003, 2: 16–18.

WANG G M. Discuss of high purity graphite production process [J]. Non-metallic, 2001, 24(4): 30–31.

LU X J, FORSSBERG E. Preparation of high-purity and low-sulphur graphite from Woxna fine graphite concentrate by alkali roasting [J]. Minerals Engineering, 2002, 15(10): 755–757.

GB 2001-91, Coke-Determination of proximate analysis [S]. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(51274240, 51204209) supported by the National Natural Science Foundation of China; Project(2012M521545) supported by the National Postdoctoral Science Foundation of China

Rights and permissions

About this article

Cite this article

Yang, J., Ma, Ll. & Zhou, Xy. Purification process of coal-based coke powder as anode for Li-ion batteries. J. Cent. South Univ. 21, 857–861 (2014). https://doi.org/10.1007/s11771-014-2010-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-014-2010-8