Abstract

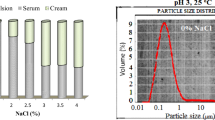

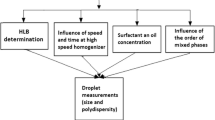

To destabilize the emulsion formed during aqueous extraction processing (AEP) of peanuts, Tween and Span series surfactants (Tween 20, Tween 80, Span 20, and Span 80) were used alone or in combination to break the emulsion. Results indicate that only Tween surfactants had a pronounced demulsifying effect that was dependent on Tween concentration and system pH. When 1.2 wt% Tween 20 aqueous solution was used for oil extraction at pH 10.0, the highest free oil yield was achieved at 76.1 %, which was similar to the oil recovery of using proteases as a destabilization agent. The results obtained using a model emulsion system containing peanut oil and Tween 20/peanut protein isolates (PPI) showed that when Tween 20 and PPI coexisted in extraction medium at pH 10.0, the dynamic interfacial tension and droplet size distribution curves were very similar to those when Tween 20 was used alone, suggesting that Tween 20 dominated at the interface, instead of PPI. Destabilization of the model emulsions relied on three important factors: inclusion of Tween 20 at the initial mixing stage, high pH, and a gentle mixing speed. A synergistic destabilization mechanism of using Tween 20 at high pH during AEP was proposed. The discovery of Tween 20 as an effective demulsifier significantly contributes to the development of AEP of oilseeds.

Similar content being viewed by others

References

Rosenthal A, Pyle DL, Niranjan K (1996) Aqueous and enzymatic processes for edible oil extraction. Enzyme Microb Technol 19:402–420

Yusoff MM, Gordon MH, Niranjan K (2015) Aqueous enzyme assisted oil extraction from oilseeds and emulsion de-emulsifying methods: a review. Trends Food Sci Tech 41:60–82

Campbell KA, Glatz CE (2009) Mechanisms of aqueous extraction of soybean oil. J Agric Food Chem 57:10904–10912

Li P, Gasmalla MAA, Zhang W, Liu J, Bing R, Yang R (2016) Effects of roasting temperatures and grinding type on the yields of oil and protein obtained by aqueous extraction processing. J Food Eng 173:15–24

de Moura JMN, Maurer D, Jung S, Johnson LA (2011) Pilot-plant proof-of-concept for integrated, countercurrent, two-stage, enzyme-assisted aqueous extraction of soybeans. J Am Oil Chem Soc 88:1649–1658

Zhang SB, Lu QY, Yang HS, Li Y, Wang S (2011) Aqueous enzymatic extraction of oil and protein hydrolysates from roasted peanut seeds. J Am Oil Chem Soc 88:727–732

Chabrand RM, Kim HJ, Zhang C, Glatz CE, Jung S (2008) Destabilization of the emulsion formed during aqueous extraction of soybean oil. J Am Oil Chem Soc 85:383–390

Wu J, Johnson LA, Jung S (2009) Demulsification of oil-rich emulsion from enzyme-assisted aqueous extraction of extruded soybean flakes. Bioresour Technol 100:527–533

Zhang SB, Liu XJ, Lu QY, Wang ZW, Zhao X (2013) Enzymatic demulsification of the oil-rich emulsion obtained by aqueous extraction of peanut seeds. J Am Oil Chem Soc 90:1261–1270

Lam RSH, Nickerson MT (2013) Food proteins: a review on their emulsifying properties using a structure-function approach. Food Chem 141:975–984

Tuntiwiwattanapun N, Tongcumpou C, Haagenson D, Wiesenborn D (2013) Development and scale-up of aqueous surfactant-assisted extraction of canola oil for use as biodiesel feedstock. J Am Oil Chem Soc 90:1089–1099

Do LD, Sabatini DA (2010) Aqueous extended-surfactant based method for vegetable oil extraction: proof of concept. J Am Oil Chem Soc 87:1211–1220

Wilde P, Mackie A, Husband F, Gunning P, Morris V (2004) Proteins and emulsifiers at liquid interfaces. Adv Colloid Interfac 108–109:63–71

van Aken GA (2003) Competitive adsorption of protein and surfactants in highly concentrated emulsions: effect on coalescence mechanisms. Colloids Sur A Physicochem Eng Asp 213:209–219

Fang L, Wang T, Lamsal B (2015) Synergistic effect of surfactants and silica nanoparticles on oil recovery from condensed corn distillers solubles (CCDS). Ind Crop Prod 77:553–559

Zhao G, Liu Y, Zhao M, Ren J, Yang B (2011) Enzymatic hydrolysis and their effects on conformation and functional properties of peanut protein isolate. Food Chem 127:1438–1443

Kaltsa O, Paximada P, Mandala I, Scholten E (2014) Physical characteristics of submicron emulsions upon partial displacement of whey protein by a small molecular weight surfactant and pectin addition. Food Res Int 66:401–408

Touhami Y, Neale GH, Hornof V, Khalfalah H (1996) A modified pendant drop method for transient and dynamic interfacial tension measurement. Colloids Sur A Physicochem Eng Asp 112:31–41

American Oil Chemists’ Society (2009) Official methods and recommended practices of the American Oil Chemists’ Society, 6th edn. AOCS Press, Champaign

McClements DJ (2005) Food emulsions: principles, practice and techniques, 2nd edn. CRC Press Taylor & Francis Group, Boca Raton

Krägel J, Wüstneck R, Husband F, Wilde PJ, Makievski AV, Grigoriev DO, Li JB (1999) Properties of mixed protein/surfactant adsorption layers. Colloids Surf B 12:399–407

Wüstneck R, Krägel J, Miller R, Wilde PJ, Clark DC (1996) The adsorption of surface-active complexes between β-casein, β-lactoglobulin and ionic surfactants and their shear rheological behaviour. Colloids Sur A Physicochem Eng Asp 114:255–265

Jiang L, Hua D, Wang Z, Xu S (2010) Aqueous enzymatic extraction of peanut oil and protein hydrolysates. Food Bioprod Process 88:233–238

Hsu JP, Nacu A (2003) Behavior of soybean oil-in-water emulsion stabilized by nonionic surfactant. J Colloid Interf Sci 259:374–381

Acknowledgments

This research has been supported financially by the China Scholarship Council and the Program for Science & Technology Innovation Talents in Universities of Henan Province (13HASTIT005) and the National Natural Science Foundation of China (31430067) and (31671887).

Author information

Authors and Affiliations

Corresponding authors

About this article

Cite this article

Zhang, S.B., Wang, T. Destabilization of Emulsion Formed During Aqueous Extraction of Peanut Oil: Synergistic Effect of Tween 20 and pH. J Am Oil Chem Soc 93, 1551–1561 (2016). https://doi.org/10.1007/s11746-016-2899-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-016-2899-1