Abstract

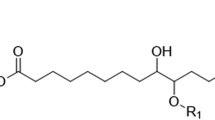

The impact of replacing three polyether polyols with different levels of a single palm olein-based natural oil polyol (NOP) was systematically correlated with the changes in foaming reactivity, cell structure, physico-mechanical properties, and morphology of viscoelastic (VE) foams. The data show that replacing the polyether polyols with the NOP slightly increased the rate of the foaming reactivity. Increasing the NOP content resulted in increased cell size and cells remained fully open. Increased NOP content contributed to higher load bearing properties of VE foam, which can be attributed to higher functionality of NOP compared to polyether polyols. Addition of the NOP slightly increased the resilience of the foams, however, the hysteresis which is the measure of energy absorption remained mostly unaffected. Age properties, characterized by dry and humid compression sets, were mostly unaffected by the replacement of the polyether polyol with the NOP. The addition of NOP did not impact the morphology of the VE foam polymer matrix, which appears to retain a low degree of hard and soft segment domain separation. Overall, the results demonstrate a feasibility that the NOP can be used to partially replace the polyether polyols in VE polyurethane foams without significant impact on the functional performance.

Similar content being viewed by others

References

Hill K (2000) Fats and oils as oleochemical raw materials. Pure Appl Chem 72(7):1255–1264

Petrović ZS (2010) Polymers from biological oils. Contemp Mater 1:39–50

Desroches M, Escouvois M, Auvergne R, Caillol S, Boutevin B (2012) From vegetable oils to polyurethanes: synthetic routes to polyols and main industrial products. Polym Rev 52(1):38–79

Petrović ZS (2008) Polyurethanes from vegetable oils. Polym Rev 48(1):109–155

End-Use Market Survey on the Polyurethanes Industry in the United States, Canada and Mexico. American Chemistry Council, Washington

Oertel G (1985) Polyurethane Handbook. Hanser, Munich

Saunders JH, Kurt CF (1962) Polyurethanes: Chemistry and Technology. Interscience, New York

Ionescu M (2005) Chemistry and technology of polyols for polyurethanes. Rapra Technology Limited, Shawbury

Herrington R, Hock K (1997) Flexible polyurethane foams. The Dow Chemical Company, Midland

Sendijarevic V (2011) Natural oil polyols in polyurethane industry—design for performance. Int Palm Oil Cong Oleo And Spec Chem Conf 3:59–71

Ionescu M, Petrović ZS, Wan X (2007) Ethoxylated soybean polyols for polyurethanes. J Polym Environ 15(4):237–243

Pawlik H, Prociak A (2012) Influence of palm oil-based polyol on the properties of flexible polyurethane foams. J Polym Environ 29:438–445

Tan S, Abraham T, Ference D, Macosko CW (2011) Rigid polyurethane foams from a soybean oil-based polyols. Polymer 52(13):2840–2846

John J, Bhattacharya M, Turner RB (2002) Characterization of polyurethane foams from soybean oil. J Appl Polym Sci 86(12):3097–3107

Guo A, Zhang W, Petrović ZS (2006) Structure-property relationships in polyurethanes derived from soybean oil. J Mater Sci 41(15):4914–4920

Campanella A, Bonnaillie LM, Wool RP (2009) Polyurethane foams from soyoil-based polyols. J Appl Polym Sci 112(4):2567–2578

Tuan Noor Maznee TI, Kosheela Devi PP, Abu Bakar ZB, Seng Soi H, Yeong SK, Hazimah AH, Schiffman C, Sendijarevic A, Sendijarevic V, Sendijarevic I (2015) Urethane-forming reaction kinetics and catalysis of model palm olein polyols: quantified impact of primary and secondary hydroxyls. J Appl Polym Sci 133(5):42955

Vaughan BR, Wilkes GL, Dounis DV, McLaughlin C (2011) Effect of vegetable-based polyols in unimodal glass-transition polyurethane slabstock viscoelastic foams and some guidance for the control of their structure–property behavior. I. J Appl Polym Sci 119(5):2683–2697

Vaughan BR, Wilkes GL, Dounis DV, McLaughlin C (2011) Effect of vegetable-based polyols in unimodal glass-transition polyurethane slabstock viscoelastic foams and some guidance for the control of their structure–property behavior. II. J Appl Polym Sci 119(5):2698–2713

Polyurethane Foam Association (2003) Examining Viscoelastic Polyurethane Foam. InTouch 11(1):1–7

Mohd Noor MA, Sendijarevic V, Abuh Hassan H, Sendijarevic I, Tuan Ismail TNM, Hoong SS, Nurul Ain H, Ghazali R (2015) Polyether polyols as gpc calibration standards for determination of molecular weight distribution of polyether polyols. J Appl Polym Sci 132(43):42698

Indennidate L, Cannoletta D, Lionetto F, Greco A, Maffezzoli A (2010) Nanofilled polyols for viscoelastic polyurethane foams. Polymer Int 59(4):486–491

Sultan W, Busnel J-P (2006) Kinetic study of polyurethane formation by using differential scanning calorimetry. J Therm Anal Cal 83:355–359

Hager S, Skorpenske R, Triouleyre S, Joulak F (2001) New technology for viscoelastic foam. J Cell Plast 37(5):377–399

Kaushiva BD, Dounis DV, Wilkes GL (2010) Influence of copolymer polyol on structural and viscoelastic properties in molded flexible polyurethane foams. J Appl Polym Sci 78:766–786

Davies OL, Mills NJ (1999) The rate dependence of confor polyurethane foams. Cell Polym 18(2):117–136

Babb DA, Obi BE, O’Neill RE, Paupe-Rio-Neto A (2008) Viscoelastic foams having high air flow. WO 2008(036173):A1

Singh AP, Bhattacharya M (2004) Viscoelastic changes and cell opening of reacting polyurethane foams from soy oil. Polym Eng Sci 44(10):1977–1986

Zhang L, Jeon HK, Malsam J, Herrington R, Macosko CW (2007) Substituting soybean oil-based polyol into polyurethane flexible foams. Polymer 48(22):6656–6667

Sharma C, Kumar S, Unni A, Aswal VK, Rath SK, Harikrishnan G (2014) Foam stability and polymer phase morphology of flexible polyurethane foams synthesized from castor oil. J App Polym Sci 131(17):40668

Acknowledgments

The authors would like to thank the Malaysian Palm Oil Board (MPOB) and the Director General of MPOB for providing the financial support for this research work. The authors would also like to thank our research officers and supporting staff at the Advanced Oleochemical Technology Division (AOTD), as well as members of Troy Polymers, Inc. (TPI) for their invaluable contributions to this work.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Nurul ‘Ain, H., Maznee, T.I.T.N., Norhayati, M.N. et al. Natural Palm Olein Polyol as a Replacement for Polyether Polyols in Viscoelastic Polyurethane Foam. J Am Oil Chem Soc 93, 983–993 (2016). https://doi.org/10.1007/s11746-016-2832-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-016-2832-7