Abstract

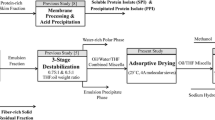

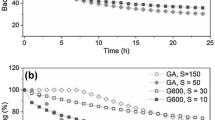

The multi-stage treatment of stable oil-in-water emulsions produced during non-enzymatic aqueous processing of dehulled yellow mustard flour with cyclic ethers [tetrahydrofuran (THF) and 1,4-dioxane] was investigated to produce a single-phase oil-solvent-water miscella suitable for biodiesel production. While the single-stage treatment of yellow mustard emulsion recovered 97 % and 95 % of the oil by using 4:1 THF:oil and 9:1 dioxane:oil weight ratios, respectively, miscella phases containing more than 7 % water formed, which made them unsuitable as biodiesel feedstock. Multi-stage treatments of the emulsion using lower THF:oil and dioxane:oil weight ratios were further developed to produce oil-solvent-water miscella phases with low water content. While three-stage extraction of emulsions using 0.5:1, 1:1, 1.5:1, and 2:1 dioxane:oil weight ratios did not destabilize the emulsion, three-stage extraction using 0.5:1 and 0.75:1 THF:oil weight ratios effectively recovered over 97 % of the oil, resulting in the production of oil-rich miscella phases containing only 1 % and 1.5 % water, respectively. These miscella phases were analyzed for free fatty acid and phosphorus contents and proved to be excellent feedstocks for the preparation of high-purity methyl esters through single-phase base-catalyzed transmethylation.

Similar content being viewed by others

References

Bell JM, Rakow G, Downey RK (2000) Comparisons of amino acid and protein levels in oil-extracted seeds of Brassica and Sinapis species, with observations on environmental effects. Can J Anim Sci 80:169–174

Lusas EW (1983) Comparative processing practices of the world’s major oilseed crops. Econ Bot 37:444–458

Lusas EW, Watkins LR, Rhee KC (1989) Separation of fats and oils by solvent extraction: non-traditional methods. In: Erickson DR (ed) Proceedings of the World Conference on edible fats and oils processing: basic principles and modern practices. AOCS Press, Champaign, pp 56–78

Chen B-K, Diosady LL (2003) Enzymatic aqueous processing of coconuts. Int J Appl Sci Eng 1:55–61

Rosenthal A, Pyle DL, Niranjan K (1996) Aqueous and enzymatic processes for edible oil extraction. Enzyme Microb Technol 19:402–420

Zhang SB, Wang Z, Xu SY (2007) Downstream processes for aqueous enzymatic extraction of rapeseed oil and protein hydrolysates. J Am Oil Chem Soc 84:693–700

Zhang SB, Wang Z, Xu SY (2007) Optimization of the aqueous enzymatic extraction of rapeseed oil and protein hydrolysates. J Am Oil Chem Soc 84:97–105

Latif S, Diosady LL, Anwar F (2008) Enzyme-assisted aqueous extraction of oil and protein from canola (Brassica napus L.) seeds. Eur J Lipid Sci Technol 110:887–892

Sengupta R, Bhattacharyya DK (1996) Enzymatic extraction of mustard seed and rice bran. J Am Oil Chem Soc 73:687–692

Campbell KA, Glatz CE, Johnson LA, Jung S, De Moura JMN, Kapchie V, Murphy P (2011) Advances in aqueous extraction processing of soybeans. J Am Oil Chem Soc 88:449–465

De Moura JMLN, De Almeida NM, Johnson LA (2009) Scale-up of enzyme-assisted aqueous extraction processing of soybeans. J Am Oil Chem Soc 86:809–815

De Moura JMLN, Johnson LA (2009) Two-stage countercurrent enzyme-assisted aqueous extraction processing of oil and protein from soybeans. J Am Oil Chem Soc 86:283–289

De Moura JMLN, Maurer D, Jung S, Johnson LA (2011) Pilot-plant proof-of-concept for integrated, countercurrent, two-stage, enzyme-assisted aqueous extraction of soybeans. J Am Oil Chem Soc 88:1649–1658

Chabrand RM, Glatz CE (2009) Destabilization of the emulsion formed during the enzyme-assisted aqueous extraction of oil from soybean flour. Enzyme Microb Technol 45:28–35

De Moura JMLN, Campbell K, Mahfuz A, Jung S, Glatz CE, Johnson L (2008) Enzyme-assisted aqueous extraction of oil and protein from soybeans and cream de-emulsification. J Am Oil Chem Soc 85:985–995

Jung S, Maurer D, Johnson LA (2009) Factors affecting emulsion stability and quality of oil recovered from enzyme-assisted aqueous extraction of soybeans. Bioresour Technol 100:5340–5347

Wu J, Johnson LA, Jung S (2009) Demulsification of oil-rich emulsion from enzyme-assisted aqueous extraction of extruded soybean flakes. Bioresour Technol 100:527–533

Tabtabaei S, Diosady LL (2013) Aqueous and enzymatic extraction processes for the production of food-grade proteins and industrial oil from dehulled yellow mustard flour. Food Res Int 52:547–556

Tabtabaei S, Ataya Pulido VM, Diosady LL (2013) Destabilization of yellow mustard emulsion using organic solvents. J Am Oil Chem Soc 90:707–716

Tabtabaei S, Diosady LL (2012) The isolation of yellow mustard oil using water and cyclic ethers. J Am Oil Chem Soc 89:935–945

Sharma YC, Singh B, Upadhyay SN (2008) Advancements in development and characterization of biodiesel: a review. Fuel 87:2355–2373

Boocock DGB, Konar SK, Mao V, Sidi H (1996) Fast one-phase oil-rich processes for the preparation of vegetable oil methyl esters. Biomass Bioenergy 11:43–50

Freedman B, Pryde EH, Mounts TL (1984) Variables affecting the yields of fatty esters from transesterified vegetable oils. J Am Oil Chem Soc 61:1638–1643

Boocock DGB, Konar SK, Sidi H (1996) Phase diagrams for oil/methanol/ether mixtures. J Am Oil Chem Soc 73:1247–1251

Boocock DGB, Konar SK, Mao V, Lee C, Buligan S (1998) Fast formation of high-purity methyl esters from vegetable oils. J Am Oil Chem Soc 75:1167–1172

Mahajan S, Konar SK, Boocock DGB (2006) Standard biodiesel from soybean oil by a single chemical reaction. J Am Oil Chem Soc 83:641–644

Mehta GD, Fraser MD (1985) A novel extraction process for separating ethanol and water. Ind Eng Chem Process Des Dev 24:556–560

Othmer DF, White RE, Trueger E (1941) Liquid-liquid extraction data. Ind Eng Chem 33:1240–1248

Du W, Xu YY, Zeng J, Liu DH (2004) Novozym 435-catalysed transesterification of crude soya bean oils for biodiesel production in a solvent-free medium. Biotechnol Appl Biochem 40:187–190

Acknowledgments

This project was funded by the Natural Sciences and Engineering Research Council of Canada through its strategic grants program. The technical assistance of Mr. Bih-King Chen and Ms. Helia Safaee is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Tabtabaei, S., Boocock, D.G.B. & Diosady, L.L. Biodiesel Feedstock from Emulsions Produced by Aqueous Processing of Yellow Mustard. J Am Oil Chem Soc 91, 1269–1282 (2014). https://doi.org/10.1007/s11746-014-2448-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-014-2448-8