Abstract

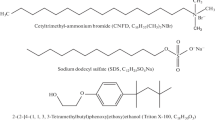

3-(N,N-Dimethyl myristyl-ammonio) propane sulfonate zwitterionic surfactant (C14-SB) which possessed both positive and negative charges was evaluated in the electroless Ni–P coating process. It was observed that the deposition rate, morphology and microhardness of the deposits were enhanced by the addition of C14-SB surfactant. The excess attractive forces from the negative head of C14-SB were strong enough to draw metallic nickel particles towards the substrate. Ni particles attempting to deposit on the electrolyte container were eliminated by the repulsive force from the positive head of the surfactant monomers. Thus, the deposition rate of the coating process was improved. The surfactant at its critical micelle concentration (CMC) doubles the deposition rate when compared to the substrate without surfactant. In addition, the microhardness of the deposit at the surfactant CMC increased by 62 %. The corrosion rate of the substrate without surfactant was 7.15 mpy, while it was 3.97 mpy for the substrate deposited with C14-SB zwitterionic surfactant at the CMC.

Similar content being viewed by others

References

Sha W, Wu X, Keong KG (2011) Electroless copper and nickel-phosphorus plating: processing, characterisation and modelling. Woodhead, Cambridge

Liu BH, Liao FY, Chen J (2013) Design fabrication and characterization of electroless Ni–P alloy films for micro heating devices. Thin Solid Films 537:263–268

Sudagar J, Lian J, Sha W (2013) Electroless nickel, alloy, composite and nano coatings—a critical review. J Alloys Compd 571:183–204

Liu HP, Li N, Bi S, Li D, Zou Z (2008) Effect of organic additives on the corrosion resistance properties of electroless nickel deposits. Thin Solid Films 516:1883–1889

Chen BH, Hong L, Ma Y, Ko TM (2002) Effects of surfactants in an electroless nickel-plating bath on the properties of Ni–P alloy deposits. Ind Eng Chem Res 41(11):2668–2678

Elansezhian R, Ramamoorthy B, Nair PK (2009) The influence of SDS and CTAB surfactants on the surface morphology and surface topography of electroless Ni–P deposits. J Mater Process Tech 209(1):233–240

Elansezhian R, Ramamoorthy B, Nair PK (2008) Effect of surfactants on the mechanical properties of electroless (Ni–P) coating. Surf Coat Tech 203(5):709–712

Alsari AM, Khulbe KC, Matsuura T (2001) The effect of sodium dodecyl sulfate solutions as gelation media on the formation of PES membranes. J Membr Sci 188(2):279–293

Medina-Valtierra J, Frausto-Reyes C, Calixto S, Bosch P, Lara VH (2007) The influence of surfactants on the roughness of titania sol–gel films. Mater Charact 58(3):233–242

Sudagar J, Lian JS, Jiang Q, Jiang ZH, Li GY, Elansezhian R (2012) The performance of surfactant on the surface characteristics of electroless nickel coating on magnesium alloy. Prog Org Coat 74(4):788–793

Abdel Hamid Z, Omar AMA (2003) Development of an electrodeposition nickel polymer composite by a zwitterionic surfactant. J Surfact Deterg 6(2):163–166

Muraliraja R, Elansezhian R (2014) Effect of zwitterionic surfactant on tribological behaviour of electroless plating. Surf Eng 30(10):752–757

Ranganatha S, Venkatesha TV, Vathsala KV (2010) Development of electroless Ni–Zn–P/nano-TiO2 composite coatings and their properties. Appl Surf Sci 25(24):7377–7383

Zhang R, Somasundaran P (2006) Advances in adsorption of surfactants and their mixtures at solid/solution. Adv Colloid Interface 123:213–229

Vitry V, Kanta AF, Delaunois (2010) Initiation and formation of electroless nickel–boron coatings on mild steel: effect of substrate roughness. Mater Sci Eng B 175(3):266–273

Tamilarasan TR, Rajendran R, Rajagopal G, Sudagar J (2015) Effect of surfactants on the coating properties and corrosion behaviour of Ni–P–nano-TiO 2 coatings. Surf Coat Tech 276:320–326

Elansezhian R, Ramamoorthy B, Nair PK (2012) Study on characterisation and influence of surfactants on adhesion and coating thickness of electroless Ni–P deposits. Int J Microstruct Mater Prop 7(1):77–93

Jappes JW, Ramamoorthy B, Nair PK (2005) A study on the influence of process parameters on efficiency and crystallinity of electroless Ni–P deposits. J Mater Process Tech 169(2):308–313

Shinoda K (1968) Solvent properties of surfactant solutions. Soil Sci 106(4):323

Nilsson G (1957) The adsorption of tritiated sodium dodecyl sulfate at the solution surface measured with a windowless, high humidity gas flow proportional counter. J Phys Chem 61(9):1135–1142

Chen YY, Duh JG, Chiou BS (2000) The effect of substrate surface roughness on the wettability of Sn–Bi solders. J Mater Sci Mater Electron 11(4):279–283

Young BL, Duh JG, Chiou BS (2001) Wettability of electroless Ni in the under bump metallurgy with lead free solder. J Electron Mater 30(5):543–553

Keong KG, Sha W, Malinov S (2003) Hardness evolution of electroless nickel–phosphorus deposits with thermal processing. Surf Coat Tech 168(2):263–274

Yan M, Ying HG, Ma TY (2008) Improved microhardness and wear resistance of the as-deposited electroless Ni–P coating. Surf Coat Tech 202(24):5909–5913

Che L, Xiao M, Xu H, Wang B, Jin Y (2013) Enhanced corrosion resistance and microhardness of titanium with electroless deposition Ni–W–Cr–P Coating. Mater Manuf Processes 28(8):899–904

Acknowledgments

The authors would like to thank the central instrumentation facility (CIF), Pondicherry University, for providing SEM, EDS facilities. The authors are grateful to Mr. Ramnath, Department of Metallurgical and Materials Engineering, Indian Institute of Technology Madras, who carried out the language correction for this paper.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Muraliraja, R., Elansezhian, R., Sudagar, J. et al. Influence of a Zwitterionic Surfactant on the Surface Properties of Electroless Ni–P Coating on Mild Steel. J Surfact Deterg 19, 1081–1088 (2016). https://doi.org/10.1007/s11743-016-1858-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-016-1858-z