Abstract

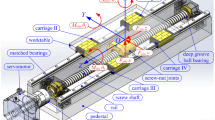

In the product development process numerical optimization can successfully be applied in the early product design stages. In the very common case of ball screw drives, the dynamical behavior is most depending on the geometrical shape of the ball screw itself. Properties like axial and torsional stiffness, moment of inertia, maximum velocity and acceleration are determined not only by the servo motor but also by screw diameter, slope and ball groove radius. Furthermore coupling effects between the design variables make the optimization task even more difficult. In order to capture these effects, efficient numerical (usually FEM or MBS) models are needed. In this work a new more accurate and efficient method of computing the axial and torsional stiffness of ball screw spindles is presented. We analytically derive parametric equations which depicts most of the dependencies of stiffness on geometrical parameters of the screw. Furthermore, we enhance the analytical model with an identified function, which increase the accuracy even more. The presented analytical model is validated against FEM model and catalog data with the help of numerous examples.

Similar content being viewed by others

References

Jarosch P, Zur Lebensdauerprognose zyklisch hoch belasteter Kugelgewindetriebe. In: Berichte aus der Kunsstofftechnik, Shaker Verlag 2008

Dambacher U (2005) Kugelgewindetriebe mit hohem Druckwinkel. Disseration Fakultät für Maschinenbau der Universität Karlsruhe (TH)

Frank T (2001) Vergleichende Untersuchungen schneller elektromechanischerVorschubachsen mit Kugelgewindetrieb. In: Forschungsberichte aus dem Institut für Werkzeugmaschinen und Betriebstechnik der Universität Karlsruhe, Band 105

Stein E (1967) Die Berechnung von Trägern mit in Stablängsrichtung um den Schwerpunkt verdrehtem Querschnitt. In: Der Stahlbau, 5/1967

Messager T, Cartraud P (2008) Homogenization of helical beam-like structures. Computational Mechanics 41:335–346

Banerjee JR (2001) Free vibration of a twisted beam using the dynamic stiffness method. Int J Solids Struct 38:6703–6722

Deutsche Norm (1989) Machine Tools; Ball Screws, Terminology, Designation System. In: DIN 69051, Part 1, 1989

ANSYS, Inc. (2009) Documentation for ANSYS, v12, 2009

Bosch Rexroth (2009) Kugelgewindetriebe. In: Bosch Catalog R310DE 3301 (2009.08), 122, 2009

Müller PH (ed) (1991) Lexikon der Stochastik, 5th edn. Berlin: Akademie Verlag

Acknowledgments

This research was supported by the Institute of Control of Manufacturing Units Stuttgart (ISW), by the excellence cluster SimTech Stuttgart and GSaME Stuttgart. This support is highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dadalau, A., Mottahedi, M., Groh, K. et al. Parametric modeling of ball screw spindles. Prod. Eng. Res. Devel. 4, 625–631 (2010). https://doi.org/10.1007/s11740-010-0264-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-010-0264-z