Abstract

Polyetheretherketone (PEEK) is regarded as one of the most potential candidates for replacing current implant applications. To obtain good bone-implant interfaces, many modification methods have been developed to enable PEEK and PEEK-based composites from bio-inert to bioactive. Among them, physical methods have aroused significant attention and been widely used to modify PEEK for orthopedic implants. This review summarizes current physical modification techniques of PEEK for orthopedic applications, which include composite strategies, surface coating methods and irradiation treatments. The positive consequences of those modification methods will encourage continuing investigations and stimulate the wide range of applications of PEEK-based implants in orthopedics.

Similar content being viewed by others

References

Stolarski T A. Tribology of polyetheretherketone. Wear, 1992, 158(1–2): 71–78

Bishop S M. The mechanical performance and impact behaviour of carbon-fibre reinforced PEEK. Composite Structures, 1985, 3(3–4): 295–318

Fujihara K, Huang Z M, Ramakrishna S, et al. Feasibility of knitted carbon/PEEK composites for orthopedic bone plates. Biomaterials, 2004, 25(17): 3877–3885

Searle O B, Pfeiffer R H. Victrex® poly (ethersulfone) (PES) and Victrex® poly (etheretherketone) (PEEK). Polymer Engineering and Science, 1985, 25(8): 474–476

Jamison R D, Maharaj G R. Intraoperative impact: characterization and laboratory simulation on composite hip prostheses. In: Jamison R D, Gilbertson L N, Composite Materials for Implant Applications in the Human Body: Characterization and Testing. ASTM International STP 1178, 1993, 98–108

Kurtz S M, Devine J N. PEEK biomaterials in trauma, orthopedic, and spinal implants. Biomaterials, 2007, 28(32): 4845–4869

Saito N, Aoki K, Usui Y, et al. Application of carbon fibers to biomaterials: a new era of nano-level control of carbon fibers after 30-years of development. Chemical Society Reviews, 2011, 40(7): 3824–3834

Williams D F, McNamara A, Turner R M. Potential of polyetheretherketone (PEEK) and carbon-fibre-reinforced PEEK in medical applications. Journal of Materials Science Letters, 1987, 6(2): 188–190

Wenz L M, Merritt K, Brown S A, et al. In vitro biocompatibility of polyetheretherketone and polysulfone composites. Journal of Biomedical Materials Research, 1990, 24(2): 207–215

Hunter A, Archer C W, Walker P S, et al. Attachment and proliferation of osteoblasts and fibroblasts on biomaterials for orthopaedic use. Biomaterials, 1995, 16(4): 287–295

Pioch T, Stotz S, Staehle H J, et al. Applications of confocal laser scanning microscopy to dental bonding. Advances in Dental Research, 1997, 11(4): 453–461

Scotchford C A, Garle C, Batchelor J, et al. Use of a novel carbon fibre composite material for the femoral stem component of a THR system: in vitro biological assessment. Biomaterials, 2003, 24(26): 4871–4879

Lin TW, Corvelli A A, Frondoza C G, et al. Glass peek composite promotes proliferation and osteocalcin production of human osteoblastic cells. Journal of Biomedical Materials Research, 1997, 36(2): 137–144

Katzer A, Marquardt H, Westendorf J, et al. Polyetheretherketone cytotoxicity and mutagenicity in vitro. Biomaterials, 2002, 23(8): 1749–1759

Jockisch K A, Brown S A, Bauer TW, et al. Biological response to chopped-carbon-fiber-reinforced peek. Journal of Biomedical Materials Research, 1992, 26(2): 133–146

Schwitalla A, Müller W D. PEEK dental implants: a review of the literature. The Journal of Oral Implantology, 2013, 39(6): 743–749

Rattier B D, Hoffman A S, Schoen F J, et al. Biomaterials science: an introduction to materials in medicine. Journal of Clinical Engineering, 1997, 22(1): 26

Brennan W J, Feast W J, Munro H S, et al. Investigation of the ageing of plasma oxidized PEEK. Polymer, 1991, 32(8): 1527–1530

Briem D, Strametz S, Schröoder K, et al. Response of primary fibroblasts and osteoblasts to plasma treated polyetheretherketone (PEEK) surfaces. Journal of Materials Science: Materials in Medicine, 2005, 16(7): 671–677

Charest J L, Eliason M T, García A J, et al. Combined microscale mechanical topography and chemical patterns on polymer cell culture substrates. Biomaterials, 2006, 27(11): 2487–2494

Anselme K, Linez P, Bigerelle M, et al. The relative influence of the topography and chemistry of TiAl6V4 surfaces on osteoblastic cell behaviour. Biomaterials, 2000, 21(15): 1567–1577

Roeder R K, Converse G L, Kane R J, et al. Hydroxyapatitereinforced polymer biocomposites for synthetic bone substitutes. JOM, 2008, 60(3): 38–45

Wang Q Q, Wu J J, Unsworth A, et al. Biotribological study of large diameter ceramic-on-CFR-PEEK hip joint including fluid uptake, wear and frictional heating. Journal of Materials Science: Materials in Medicine, 2012, 23(6): 1533–1542

Scholes S C, Unsworth A. The wear performance of PEEKOPTIMA based self-mating couples. Wear, 2010, 268(3–4): 380–387

Doorn P F, Campbell P A, Amstutz H C. Metal versus polyethylene wear particles in total hip replacements. A review. Clinical Orthopaedics and Related Research, 1996, 329(Suppl): S206–S216

Catelas I, Huk O L, Petit A, et al. Flow cytometric analysis of macrophage response to ceramic and polyethylene particles: effects of size, concentration, and composition. Journal of Biomedical Materials Research, 1998, 41(4): 600–607

Ingham E, Fisher J. Biological reactions to wear debris in total joint replacement. Proceedings of the Institution of Mechanical Engineers Part H: Journal of Engineering in Medicine, 2000, 214(1): 21–37

Ingram J H, Stone M, Fisher J, et al. The influence of molecular weight, crosslinking and counterface roughness on TNF-α production by macrophages in response to ultra high molecular weight polyethylene particles. Biomaterials, 2004, 25(17): 3511–3522

Xiong D, Xiong L, Liu L. Preparation and tribological properties of polyetheretherketone composites. Journal of Biomedical Materials Research Part B: Applied Biomaterials, 2010, 93B(2): 492–496

Rousseau M A, Lazennec J Y, Saillant G. Circumferential arthrodesis using PEEK cages at the lumbar spine. Journal of Spinal Disorders & Techniques, 2007, 20(4): 278–281

Pape D, Adam F, Fritsch E, et al. Primary lumbosacral stability after open posterior and endoscopic anterior fusion with interbody implants: a roentgen stereophotogrammetric analysis. Spine, 2000, 25(19): 2514–2518

McMillin C R. Evaluation of PEKEKK composites for spine implants. In: 38th International SAMPE Symposium, Anaheim, CA, USA. 1993, 591–598

Dickinson A S, Taylor A C, Browne M. The influence of acetabular cup material on pelvis cortex surface strains, measured using digital image correlation. Journal of Biomechanics, 2012, 45(4): 719–723

Kim I Y, Sugino A, Kikuta K, et al. Bioactive composites consisting of PEEK and calcium silicate powders. Journal of Biomaterials Applications, 2009, 24(2): 105–118

Scotchford C A, Garle M J, Batchelor J, et al. Use of a novel carbon fibre composite material for the femoral stem component of a THR system: in vitro biological assessment. Biomaterials, 2003, 24(26): 4871–4879

Sagomonyants K B, Jarman-Smith M L, Devine J N, et al. The in vitro response of human osteoblasts to polyetheretherketone (PEEK) substrates compared to commercially pure titanium. Biomaterials, 2008, 29(11): 1563–1572

Bonfield W, Grynpas M D, Tully A E, et al. Hydroxyapatite reinforced polyethylene — a mechanically compatible implant material for bone replacement. Biomaterials, 1981, 2(3): 185–186

Abu Bakar M S, Cheng M H W, Tang S M, et al. Tensile properties, tension-tension fatigue and biological response of polyetheretherketone-hydroxyapatite composites for load-bearing orthopedic implants. Biomaterials, 2003, 24(13): 2245–2250

Yu S, Hariram K P, Kumar R, et al. In vitro apatite formation and its growth kinetics on hydroxyapatite/polyetheretherketone biocomposites. Biomaterials, 2005, 26(15): 2343–2352

Wang L, Weng L, Song S, et al. Mechanical properties and microstructure of polyetheretherketone-hydroxyapatite nano composite materials. Materials Letters, 2010, 64(20): 2201–2204

Ma R, Weng L, Bao X, et al. Characterization of in situ synthesized hydroxyapatite/polyetheretherketone composite materials. Materials Letters, 2012, 71: 117–119

Ma R, Weng L, Bao X, et al. In vivo biocompatibility and bioactivity of in situ synthesized hydroxyapatite/polyetheretherketone composite materials. Journal of Applied Polymer Science, 2013, 127(4): 2581–2587

Ma R, Fang L, Luo Z, et al. Mechanical performance and in vivo bioactivity of functionally graded PEEK-HA biocomposite materials. Journal of Sol-Gel Science and Technology, 2014, 1: 1–7

Wang M, Joseph R, Bonfield W. Hydroxyapatite-polyethylene composites for bone substitution: effects of ceramic particle size and morphology. Biomaterials, 1998, 19(24): 2357–2366

Santos C, Luklinska Z B, Clarke R L, et al. Hydroxyapatite as a filler for dental composite materials: mechanical properties and in vitro bioactivity of composites. Journal of Materials Science: Materials in Medicine, 2001, 12(7): 565–573

Wong K L, Wong C T, Liu W C, et al. Mechanical properties and in vitro response of strontium-containing hydroxyapatite/polyetheretherketone composites. Biomaterials, 2009, 30(23–24): 3810–3817

Li Y W, Leong J C Y, Lu W W, et al. A novel injectable bioactive bone cement for spinal surgery: a developmental and preclinical study. Journal of Biomedical Materials Research, 2000, 52(1): 164–170

Shorr E, Carter A C. The usefulness of strontium as an adjuvant to calcium in the remineralization of the skeleton in man. Bulletin of the Hospital for Joint Diseases, 1952, 13(1): 59–66

Cox S C, Jamshidi P, Grover L M, et al. Preparation and characterisation of nanophase Sr, Mg, and Zn substituted hydroxyapatite by aqueous precipitation. Materials Science and Engineering C, 2014, 35: 106–114

Okayama S, Akao M, Nakamura S, et al. The mechanical properties and solubility of strontium-substituted hydroxyapatite. Bio-Medical Materials and Engineering, 1991, 1(1): 11–17

Boanini E, Torricelli P, Fini M, et al. Osteopenic bone cell response to strontium-substituted hydroxyapatite. Journal of Materials Science: Materials in Medicine, 2011, 22(9): 2079–2088

Qi Z, Zhang Q, Dai H, et al. Effects of β-TCP ceramics on intracellular Ca2+ concentration, mineralization of osteoblast and protein structure. Journal of Wuhan University of Technology (Materials Science Edition), 2011, 26(6): 1064–1067

Petrovic L, Pohle D, Münstedt H, et al. Effect of β-TCP filled polyetheretherketone on osteoblast cell proliferation in vitro. Journal of Biomedical Science, 2006, 13(1): 41–46

von Wilmowsky C, Vairaktaris E, Pohle D, et al. Effects of bioactive glass and β-TCP containing three-dimensional laser sintered polyetheretherketone composites on osteoblasts in vitro. Journal of Biomedical Materials Research Part A, 2008, 87A(4): 896–902

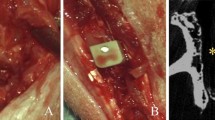

VonWilmonsky C, Lutz R, Meisel U, et al. In vivo evaluation of β-TCP containing 3D laser sintered poly (ether ether ketone) composites in pigs. Journal of Bioactive and Compatible Polymers, 2009, 24(2): 169–184

Suska F, Omar O, Emanuelsson L, et al. Enhancement of CRFPEEK osseointegration by plasma-sprayed hydroxyapatite: A rabbit model. Journal of Biomaterials Applications, 2014, 29(2): 234–242

Lee J H, Jang H L, Lee KM, et al. In vitro and in vivo evaluation of the bioactivity of hydroxyapatite-coated polyetheretherketone biocomposites created by cold spray technology. Acta Biomaterialia, 2013, 9(4): 6177–6187

Gardon M, Latorre A, Torrell M, et al. Cold gas spray titanium coatings onto a biocompatible polymer. Materials Letters, 2013, 106: 97–99

Fauchais P, Vardelle A, Dussoubs B. Quo vadis thermal spraying? Journal of Thermal Spray Technology, 2001, 10(1): 44–66

Fauchais P. Understanding plasma spraying. Journal of Physics D: Applied Physics, 2004, 37(9): R86–R108

Furlong R J, Osborn J F. Fixation of hip prostheses by hydroxyapatite ceramic coatings. The Journal of Bone and Joint Surgery (British Volume), 1991, 73(5): 741–745

Montanaro L, Arciola C R, Campoccia D, et al. In vitro effects on MG63 osteoblast-like cells following contact with two roughnessdiffering fluorohydroxyapatite-coated titanium alloys. Biomaterials, 2002, 23(17): 3651–3659

Kurtz S M. PEEK Biomaterials Handbook. Oxford, UK: William Andrew, 2011, 145–161

Tsui Y C, Doyle C, Clyne T W. Plasma sprayed hydroxyapatite coatings on titanium substrates. Part 1: Mechanical properties and residual stress levels. Biomaterials, 1998, 19(22): 2015–2029

Marrocco T, McCartney D G, Shipway P H, et al. Production of titanium deposits by cold-gas dynamic spray: Numerical modeling and experimental characterization. Journal of Thermal Spray Technology, 2006, 15(2): 263–272

Lupoi R, O’Neill W. Deposition of metallic coatings on polymer surfaces using cold spray. Surface and Coatings Technology, 2010, 205(7): 2167–2173

Hahn B D, Park D S, Choi J J, et al. Osteoconductive hydroxyapatite coated PEEK for spinal fusion surgery. Applied Surface Science, 2013, 283: 6–11

Yao C, Storey D, Webster T J. Nanostructured metal coatings on polymers increase osteoblast attachment. International Journal of Nanomedicine, 2007, 2(3): 487–492

Han CM, Lee E J, Kim H E, et al. The electron beam deposition of titanium on polyetheretherketone (PEEK) and the resulting enhanced biological properties. Biomaterials, 2010, 31(13): 3465–3470

Barkarmo S, Wennerberg A, Hoffman M, et al. Nano-hydroxyapatite-coated PEEK implants: a pilot study in rabbit bone. Journal of Biomedical Materials Research Part A, 2013, 101A(2): 465–471

Jung H D, Sun Park H, Kang M H, et al. Polyetheretherketone/magnesium composite selectively coated with hydroxyapatite for enhanced in vitro bio-corrosion resistance and biocompatibility. Materials Letters, 2014, 116: 20–22

Ha S W, Hauert R, Ernst K H, et al. Surface analysis of chemically-etched and plasma-treated polyetheretherketone (PEEK) for biomedical applications. Surface and Coatings Technology, 1997, 96(2–3): 293–299

Rochford E T J, Poulsson A H C, Salavarrieta Varela J, et al. Bacterial adhesion to orthopaedic implant materials and a novel oxygen plasma modified PEEK surface. Colloids and Surfaces B: Biointerfaces, 2014, 113: 213–222

Garbassi F, Morra M, Occhiello E. Polymer Surfaces: from Physics to Technology. Chichester, UK: John Wiley and Sons, 1994, 221–454

Mathieson I, Bradley R H. Effects of ultraviolet/ozone on the surface chemistry of polymer films. Advanced Engineering Materials, 1994, 99(100): 185–191

Riveiro A, Soto R, Comesana R, et al. Laser surface modification of PEEK. Applied Surface Science, 2012, 258(23): 9437–9442

Akkan C K, Hammadeh M, Brück S, et al. Plasma and short pulse laser treatment of medical grade PEEK surfaces for controlled wetting. Materials Letters, 2013, 109: 261–264

Mangipudi V, Tirrell M, Pocius A V. Direct measurement of the surface energy of corona-treated polyethylene using the surface forces apparatus. Langmuir, 1995, 11(1): 19–23

Strobel M, Walzak M J, Hill J M, et al. A comparison of gas-phase methods of modifying polymer surfaces. Journal of Adhesion Science and Technology, 1995, 9(3): 365–383

Sasuga T, Hagiwara M. Mechanical relaxation of crystalline poly (aryl-ether-ether-ketone) (PEEK) and influence of electron beam irradiation. Polymer, 1986, 27(6): 821–826

Iwanaga S, Akiyama Y, Kikuchi A, et al. Fabrication of a cell array on ultrathin hydrophilic polymer gels utilising electron beam irradiation and UV excimer laser ablation. Biomaterials, 2005, 26(26): 5395–5404

Kim K H, Cho J S, Choi D J, et al. Hydrophilic group formation and cell culturing on polystyrene Petri-dish modified by ionassisted reaction. Nuclear Instruments & Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2001, 175–177: 542–547

Khoury J, Kirkpatrick S R, Maxwell M, et al. Neutral atom beam technique enhances bioactivity of PEEK. Nuclear Instruments & Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2013, 307: 630–634

Matrab T, Chehimi M M, Boudou J P, et al. Surface functionalization of ultrananocrystalline diamond using atom transfer radical polymerization (ATRP) initiated by electro-grafted aryldiazonium salts. Diamond and Related Materials, 2006, 15(4–8): 639–644

Kyomoto M, Moro T, Takatori Y, et al. Self-initiated surface grafting with poly(2-methacryloyloxyethyl phosphorylcholine) on poly(ether-ether-ketone). Biomaterials, 2010, 31(6): 1017–1024

Kyomoto M, Ishihara K. Self-initiated surface graft polymerization of 2-methacryloyloxyethyl phosphorylcholine on poly(ether ether ketone) by photoirradiation. ACS Applied Materials & Interfaces, 2009, 1(3): 537–542

Lego B, Skene W G, Giasson S. Unprecedented covalently attached ATRP initiator onto OH-functionalized mica surfaces. Langmuir, 2008, 24(2): 379–382

Jin Z, Feng W, Zhu S, et al. Protein-resistant polyurethane by sequential grafting of poly(2-hydroxyethyl methacrylate) and poly (oligo(ethylene glycol) methacrylate) via surface-initiated ATRP. Journal of Biomedical Materials Research Part A, 2010, 95A(4): 1223–1232

Fu K Y, Cheung T L, Mei Y F, et al. Surface modification of polymeric materials by plasma immersion ion implantation. Nuclear Instruments & Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2005, 237(1–2): 417–421

Lu T, Qiao Y Q, Liu X Y. Surface modification of biomaterials using plasma immersion ion implantation and deposition. Interface Focus, 2012, 2(3): 325–336

Hegemann D, Brunner H, Oehr C. Plasma treatment of polymers for surface and adhesion improvement. Nuclear Instruments & Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2003, 208: 281–286

Liu X M, Wu S L, Chu P K, et al. Effects of water plasma immersion ion implantation on surface electrochemical behavior of NiTi shape memory alloys in simulated body fluids. Applied Surface Science, 2007, 253(6): 3154–3159

Chan C M, Ko T M, Hiraoka H. Polymer surface modification by plasmas and photons. Surface Science Reports, 1996, 24(1–2): 1–54

Ahad I U, Bartnik A, Fiedorowicz H, et al. Surface modification of polymers for biocompatibility via exposure to extreme ultraviolet radiation. Journal of Biomedical Materials Research Part A, 2013 doi: 10.1002/jbm.a.34958

Poulsson A H C, Mitchell S A, Davidson MR, et al. Attachment of human primary osteoblast cells to modified polyethylene surfaces. Langmuir, 2009, 25(6): 3718–3727

Davidson M R, Mitchell S A, Bradley R H. Surface studies of low molecular weight photolysis products from UV-ozone oxidized polystyrene. Surface Science, 2005, 581(2–3): 169–177

Laurens P, Ould Bouali M, Meducin F, et al. Characterization of modifications of polymer surfaces after excimer laser treatments below the ablation threshold. Applied Surface Science, 2000, 154–155: 211–216

Laurens P, Sadras B, Decobert F, et al. Enhancement of the adhesive bonding properties of PEEK by excimer laser treatment. International Journal of Adhesion and Adhesives, 1998, 18(1): 19–27

Kirkpatrick A, Kirkpatrick S, Walsh M, et al. Investigation of accelerated neutral atom beams created from gas cluster ion beams. Nuclear Instruments & Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2013, 307: 281–289

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Du, YW., Zhang, LN., Hou, ZT. et al. Physical modification of polyetheretherketone for orthopedic implants. Front. Mater. Sci. 8, 313–324 (2014). https://doi.org/10.1007/s11706-014-0266-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11706-014-0266-4