Abstract

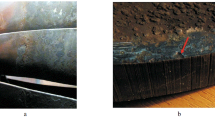

The failure of a gas turbine blade, made of a nickel-base superalloy GTD-111, was studied by metallurgical approaches. The turbine has been operating for around 73,500 h before the blade failure. As a result of the blade failure, the turbine was damaged rigorously. The analysis began with a comprehensive visual examination of the turbine and the blades’ exteriors. Afterward, the examination was continued by fractography of the fracture surfaces, microstructural examinations, and chemical analysis. Fracture was found to occur by micro-cracks spreading on the leading edge as the result of hot corrosion from overheating, together with precipitation of continuous grain boundary carbides. The overheating was resulted from blockage of air channels of the blade as a consequence of improper filtration of inlet compressor air.

Similar content being viewed by others

Change history

18 October 2019

In the title for Table 5, “region A in Fig. 6b” should read “region A in Fig. 7b.

References

B. Deepanraj, P. Lawrence, G. Sankaranarayanan, Theoretical analysis of gas turbine blade by finite element method. Sci. World 9, 29–33 (2011)

W. Abbasi, S. Rahman, M.J. Metala, NDE Inspections and Lifetime Assessment of Turbine Equipment, in: Power-Gen International (2008). http://m.energy.siemens.com/mx/pool/hq/energy-topics/pdfs/en/service/PowerGen2008_NDEInspections_LifetimeAssessment_turbequip.pdf. Accessed 2008

S. Barella, M. Boniardi, S. Cincera, P. Pellin, X. Degive, S. Gijbels, Failure analysis of a third stage gas turbine blade. Eng. Fail. Anal. 18, 386–393 (2011)

H. Kim, Study of the fracture of the last stage blade in an aircraft gas turbine. Eng. Fail. Anal. 16, 2318–2324 (2009)

S. Qu, C.M. Fu, C. Dong, J.F. Tian, Z.F. Zhang, Failure analysis of the 1st stage blades in gas turbine engine. Eng. Fail. Anal. 32, 292–303 (2013)

N. Vardar, A. Ekerim, Failure analysis of gas turbine blades in a thermal power plant. Eng. Fail. Anal. 14, 743–749 (2007)

K.-S. Song, S.-G. Kim, D. Jung, Y.-H. Hwang, Analysis of the fracture of a turbine blade on a turbojet engine. Eng. Fail. Anal. 14, 877–883 (2007)

H. Kazempour-Liacy, S. Abouali, M. Akbari-Garakani, Failure analysis of a first stage gas turbine blade. Eng. Fail. Anal. 18, 517–522 (2011)

G.H. Farrahi, M. Tirehdast, E.M.K. Abad, S. Parsa, M. Motakefpoor, Failure analysis of a gas turbine compressor. Eng. Fail. Anal. 18, 474–484 (2011)

H. Kim, Crack evaluation of the fourth stage blade in a low-pressure steam turbine. Eng. Fail. Anal. 18, 907–913 (2011)

A.A. Patil, U.M. Shirsat, Study of failure analysis of gas turbine blade. IOSR J. Eng. (2010). ISBN: 2878-8719 PP 37-43

C. Stewart, Tertiary creep damage modeling of a transversely isotropic ni-based superalloy. Electronic Theses and Dissertations. 4105 (2009). https://stars.library.ucf.edu/etd/4105

S.A. Sajjadi, S. Nategh, R.I.L. Guthrie, Study of microstructure and mechanical properties of high performance Ni-base superalloy GTD-111. Mater. Sci. Eng. A 325, 484–489 (2002)

S.A. Sajjadi, S. Nategh, A high temperature deformation mechanism map for the high performance Ni-base superalloy GTD-111. Mater. Sci. Eng. A 307, 158–164 (2001)

J.-C. Chang, Y.-H. Yun, C. Choi, J.-C. Kim, Failure analysis of gas turbine buckets. Eng. Fail. Anal. 10, 559–567 (2003)

S.A. Sajjadi, S.M. Zebarjad, Study of fracture mechanisms of a Ni-base superalloy at different temperatures. J. Achiev. Mater. Manuf. Eng. 18, 227–230 (2006)

S.A. Sajjadi, S.M. Zebarjad, Effect of temperature on tensile fracture mechanisms of a Ni-base superalloy. Arch. Mater. Sci. Eng. 28, 34–40 (2007)

S. Nategh, S.A. Sajjadi, Dislocation network formation during creep in Ni-base superalloy GTD-111. Mater. Sci. Eng. A 339, 103–108 (2003)

S.S. Handa, Precipitation of Carbides in a Ni-based Superalloy (Degree Project for Master of Science with Specialization in Manufacturing Department of Engineering Science, University West, Trollhättan, 2014)

M.J. Donachie, S.J. Donachie, J. Stephen, Superalloys: a technical guide, 2nd edn. (ASM International, 2002), pp. 10–30

J.A. Goebel, F.S. Pettit, Na2SO4-induced accelerated oxidation (hot corrosion) of nickel. Metall. Mater. Trans. B 1, 1943–1954 (1970)

J.A. Goebel, F.S. Pettit, G.W. Goward, Mechanisms for the hot corrosion of nickel-base alloys. Metall. Mater. Trans. B 4, 261–278 (1973)

T.S. Sidhu, R.D. Agrawal, S. Prakash, Hot corrosion of some superalloys and role of high-velocity oxy-fuel spray coatings—a review. Surf. Coat. Technol. 198, 441–446 (2005)

T.S. Sidhu, S. Prakash, R.D. Agrawal, Hot corrosion and performance of nickel-based coatings. Curr. Sci. 90, 41–47 (2006)

N.S. Bornstein, M.A. DeCrescente, H.A. Roth, The relationship between relative oxide ion content of Na2SO4, the presence of liquid metal oxides and sulfidation attack. Metall. Trans. 4, 1799–1810 (1973)

M.R. Khajavi, M.H. Shariat, Failure of first stage gas turbine blades. Eng. Fail. Anal. 11, 589–597 (2004)

N. Eliaz, G. Shemesh, R.M. Latanision, Hot corrosion in gas turbine components. Eng. Fail. Anal. 9, 31–43 (2002)

Z. Huda, Metallurgical failure analysis for a blade failed in a gas-turbine engine of a power plant. Mater. Des. 30, 3121–3125 (2009)

R.N. Durham, B. Gleeson, D.J. Young, Factors affecting chromium carbide precipitate dissolution during alloy oxidation. Oxid. Met. 50, 139–165 (1998)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Poursaeidi, E., Aieneravaie, M., Bannazadeh, R. et al. Failure Analysis of a GTD-111 Turbine Blade Using Metallurgical Analysis and Fractography. J Fail. Anal. and Preven. 19, 1358–1369 (2019). https://doi.org/10.1007/s11668-019-00732-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-019-00732-9