Abstract

Gradual build-up of scum over the liquid steel surface in the mould gives rise to entrapped exogenous inclusions and slag patch in the cast billets. The problem is more commonly observed during the open stream casting of continuous casting of high carbon (C > 0.6 mass%) steel billets. This problem has been quite commonly observed at Tata Steel during its billet casting. Present work aimed at eliminating the problem of scum formation during open stream billet casting of high carbon steel billets. This work involved experiments in the laboratory as well as in the plant. In addition, based on liquid steel composition thermodynamic calculations were carried out for predicting the possible oxide inclusions in Mn-Si deoxidised steels. Water model experiments were carried out in a full-scale billet caster physical model for investigating the influence of tundish outlet nozzle alignment on the entrapment of scum as slag patch over the billet surface. Based on these, cause of scum formation and its exact mechanism of entrapment in cast billets were established. Finally, countermeasures were recommended to the plant. Adequacy of the proposed countermeasures was established through a series of trials in the plant before implementation. Improvement obtained from the implementation over a period of time has been reported in the paper.

Similar content being viewed by others

References

J. Madias, A. Moreno, Strategies against reoxidation of liquid steel in billet casting with metering nozzle. in Proceedings of the Iron & Steel Technology Conference, Indianapolis, Indiana, USA, 5–8 May 2014, pp. 1771–1778

B. Thomas, The making, shaping and treating of the steel. in Fluid Flow in the Mold, 11th edn, vol. 5, Chapter 14. (AISE Steel Foundation, Pittsburg, PA, 2003), pp. 1–41

W.J. Maddever, A. McLean, J.S. Luckett, G.E. Forward, An investigation of casting streams. Can. Metall. Q. 12(1), 79–88 (1973)

S.K. Choudhary, Influence of modified casting practice on steel cleanliness. ISIJ Int. 51(4), 557–565 (2011)

L. Zhang, B.G. Thomas, inclusions in continuous casting of steel. in XXIV National Steelmaking Symposium, Morelia, Mich, Mexico, 26–28 Nov 2003, pp. 138–183

B. Santillana, M. Dziuba, J. Madias, M. Oropeza, E. Fernandez, Minimisation of slag entrapment and cold drops in sidetur billets. Ironmak. Steelmak. 30(6), 511–515 (2003)

H. Mori, N. Tanaka, M. Hirai, Entrapped scum and pinholes in continuously-cast carbon steel billets. Tetsu-to-Hagane (J. Iron Steel Inst. Jpn.) 57, 1500–1513 (1971)

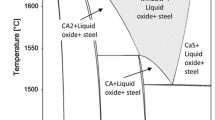

S.K. Choudhary, S. Chandra, A. Ghosh, Prediction of deoxidation and inclusion precipitation in semikilled steel. Metall. Mater. Trans. B 36B, 59–66 (2005)

Y.-B. Kang, H.-G. Lee, Inclusion chemistry for Mn/Si deoxidized steels: thermodynamic predictions and experimental confirmations. ISIJ 44(6), 1006–1015 (2004)

S.K. Choudhary, S. Chandra, Castability of Mn-Si killed low carbon wire rod steel. ISIJ Int. 47(1), 190–192 (2007)

A.D. Prasad, S.R. Sankaranarayanan, Thermodynamic modeling of deoxidation products and inclusion chemistry in Mn/Si killed tire-cord steel. J. Min. Metall. Sect. B: Metall. 48(1), 37–43 (2012)

Acknowledgments

Authors are grateful to the management of Tata Steel Ltd. for providing permission to publish the work. Valuable help received from Mr. E. Z. Chacko, Mr. Manisankar Laru, Mr. G. Dinesh, Mr. Rajesh and Mr. Vikram Sharma is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Adepu, M.K., Sahoo, P.P., Rout, B.K. et al. Prevention of Scum Formation and Entrapment in High Carbon Steel Billets. J Fail. Anal. and Preven. 17, 513–521 (2017). https://doi.org/10.1007/s11668-017-0270-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-017-0270-y