Abstract

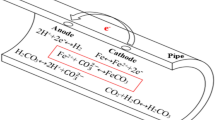

This paper presents the basic principle and practice involved in verifying that the total amount of corrosion inhibitor injected from topsides is in balance with the total amount injected from the each of the four manifold. Chemical injection metering valves (CIMV) into the respective flowlines for this field. Inadequate inhibition will significantly increase the risk of corrosion of the flowlines. Below target CI injection rates may be experienced during simultaneous injection into multiple subsea manifolds from the CIMV due to: errors in estimating the required injection flow rates and/or setting the CIMV’s; malfunction of the CIMV (e.g., instrumentation or fatigue failure); corrosion inhibitor delivery to the subsea manifolds being highly sensitive against pressure and viscosity fluctuations and thereby resulting in significant flow deviations; variable volumes of production fluids and percentage water cut. Below target injection flow rates will result in increased susceptibility to flowline corrosion while above target injection rates will result in cost penalties. The verification requirements for this subsea field are based on the mass balance principle which requires that the mass of CI injected topsides (input) should be equal to the total mass of CI injected simultaneously into all the subsea manifolds (input). It is recommended that the verification scheme should be implemented initially every 3 months during production by recording the observed CI flow rates (topsides and subsea) in the prepared data sheets, evaluating recorded data and performing corrective actions as required. Based on assessment of historic conformance of actual injection rates with target, further verification may be required during downtime, in order to determine the mass balance status and hence the CIMV performance over the full range of settings (25, 50, 75, and 100%).

Similar content being viewed by others

References

G. Willmon, M.A. Edwards, Pre-commissioning to startup: getting chemical injection right, SPE 96144. SPE Annual Technical Conference and Exhibition, Dallas, Texas, 9–12 October 2005

A.S. Al-Omari, K.M. Al-Nabulsi, A.F. Al-Marri, Failures of chemical injection points in upstream facilities. Adv. Mater. Res. 83–86, 579–591 (2009)

T. Hong, Y. Chen, Y.H. Sun, W.P. Jepson, Monitoring corrosion in multiphase pipelines. Mater. Corros. 52(8), 590–597 (2001)

R. Heidersbach, Metallurgy and Corrosion Control in Oil and Gas Production (Wiley, New York, 2011). ISBN 978-0-470-24848-5

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ifezue, D., Tobins, F.H. & Nettikaden, V.C. Verification of Corrosion Inhibitor Injection Flow Rates for a Subsea Oil/Gas Field. J Fail. Anal. and Preven. 14, 746–753 (2014). https://doi.org/10.1007/s11668-014-9879-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-014-9879-2