Abstract

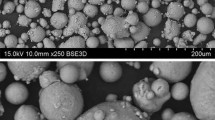

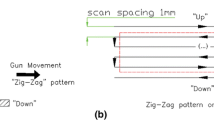

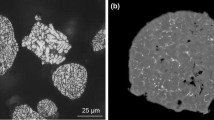

This article is dealing with the effects of surface preparation of the substrate on aluminum cold-sprayed coating bond strength. Different sets of AA2024-T3 specimens have been coated with pure Al 1050 feedstock powder, using a conventional cold spray coating technique. The sets were grit-blasted (GB) before coating. The study focuses on substrate surface topography evolution before coating and coating-substrate interface morphology after coating. To study coating adhesion by LASAT® technique for each set, specimens with and without preceding GB treatment were tested in load-controlled conditions. Then, several techniques were used to evaluate the effects of substrate surface treatment on the final coating mechanical properties. Irregularities induced by the GB treatment modify significantly the interface morphology. Results showed that particle anchoring was improved dramatically by the presence of craters. The substrate surface was characterized by numerous anchors. Numerical simulation results exhibited the increasing deformation of particle onto the grit-blasted surface. In addition, results showed a strong relationship between the coating-substrate bond strength on the deposited material and surface preparation.

Similar content being viewed by others

Notes

Surface Engineering Research Laboratory based in Belfort, France.

Available on the Material Center from MINES ParisTech based in Evry, France.

Available on the LERMPS based in Belfort, France.

Abbreviations

- AA2024-T3:

-

Aluminum Alloy 2024-T3

- GB:

-

Grit-Blasted

- CS:

-

Cold Spray

- XRD:

-

X-Ray Diffraction

- SEM:

-

Scanning Electron Microscopy

- LASAT:

-

LAser Shock Adhesion Testing

- Al:

-

Aluminum

- EOS:

-

Equation of State

- FEA:

-

Finite Element Analysis

- AIL:

-

Additional Interface Length

- RPL:

-

Representative Profile Length

- R a :

-

Arithmetic average of absolute values (µm)

- R z :

-

Average distance between the highest peak and lowest valley in each sampling length (µm)

- V p :

-

Particle velocity (m s−1)

- σ :

-

Yield strength (MPa)

- E :

-

Young’s modulus (MPa)

References

F. Gärtner, T. Stoltenhoff, T. Schmidt, and H. Kreye, The Cold Spray Process and Its Potential for Industrial Applications, J. Therm. Spray Technol., 2006, 15(2), p 223-232

J.C. Lee, H.J. Kang, W.S. Chu, and S.H. Ahn, Repair of Damaged Mold Surface by Cold-Spray Method, Manufact. Technol., 2007, 56(1), p 577-580

P.F. Leyman and V.K. Champagne, Cold Spray Process Development for the Reclamation of the Apache Helicopter Mast Support, Army Research Laboratory, ARL-TR-4922, 2009

R. Jones, N. Matthews, C.A. Rodopoulos, K. Cairns, and S. Pitt, On the Use of Supersonic Particle Deposition to Restore the Structural Integrity of Damaged Aircraft Structures, Int. J. Fatigue, 2011, 33, p 1257-1267

P. Richer, B. Jodoin, L. Ajdelsztajn, and E.J. Lavernia, Substrate Roughness and Thickness Effects on Cold Spray Nanocrystalline Al-Mg Coatings, J. Therm. Spray Technol., 2006, 15(2), p 246-254

C.W. Ziemian, M.M. Sharma, B.D. Bouffard, T. Nissley, and T.J. Eden, Effect of Substrate Surface Roughening and Cold Spray Coating on the Fatigue Life of AA2024 Specimens, Mater. Des., 2014, 54, p 212-221

M.M. Sharma, T.J. Eden, and B.T. Golesich, Effect of Surface Preparation on the Microstructure, Adhesion, and Tensile Properties of Cold-Sprayed Aluminum Coatings on AA2024 Substrates, J. Therm. Spray Technol., 2015, 24(3), p 410-422

S. Gojon, R. Kromer, H. Liao, C. Verdy, and S. Costil, Effect of Substrate Roughness on the Cratering Phenomenon in Surface Coating Using cold Spray Process, in Proceedings of the International Thermal Spray Conference (ITSC) 2015, 11-14 May, Long Beach, DVS, 2015, p 339-344

L. Berthe, M. Arrigoni, M. Boustie et al., State-of-the-art Laser Adhesion Test (LASAT), Nondestr. Test. Eval., 2011, 26(3), p 303-317

R.G. Maev, V. Leshchynsky, E. Strumban, D. Dzhurinskiy, and E. Maeva, Influence of Grit-Blasting on the Interface Roughness and Adhesion Strength of Cold-Sprayed Copper Coatings, in Proceedings of the International Thermal Spray Conference (ITSC) 2015, 11-14 May, Long Beach, DVS, 2015, p 493-497

Y. Tao, T. Xiong, C. Sun, L. Kong, X. Cui, T. Li, and G.-L. Song, Microstructure and Corrosion Performance of a Cold Sprayed Aluminum Coating on AZ91D Magnesium Alloy, Corros. Sci., 2010, 52, p 3191-3197

B.N.J. Persson, Contact Mechanics for Randomly Rough Surfaces, Surf. Sci. Rep., 2006, 61, p 201-227

S. Yin, X.-F. Wang, W.Y. Li, and H.-E. Jie, Effect of Substrate Hardness on the Deformation Behavior of Subsequently Incident Particles in Cold Spraying, Appl. Surf. Sci., 2011, 257, p 7560-7565

M. Arrigoni, M. Jeandin et al., A Comparative Study of Three Adhesion Tests (EN 582, similar to ASTM C633—LASAT (Laser Shock Adhesion Test), Bulge and Blister Test) Performed on Plasma Sprayed Copper Deposited on Aluminium 2017 Substrates, J. Adhes. Sci. Technol., 2006, 20, p 471-487

H. Sapardanis, V. Maurel, A. Köster, S. Duvinage, F. Borit, and V. Guipont, Influence of Macroscopic Shear Loading on the Growth of an Interfacial Crack Initiated from a Ceramic Blister Processed by Laser Shock, Surf. Coatings Technol., 2016, 291, p 430-433

G. Bégué, G. Fabre, V. Guipont, M. Jeandin, P. Bilhe, J.Y. Guédou, and F. Lepoutre, Laser Shock Adhesion Test (LASAT) of EB-PVD TBCs: Towards an Industrial Application, Surf. Coat. Technol., 2013, 237, p 305-312

D.K. Christoulis, S. Guetta, V. Guipont, M.-H. Berger, and M. Jeandin, Cold Spraying Combined to Laser Surface Pre-treatment using PROTAL, in Thermal Spray 2009: Proceedings of the International Thermal Spray Conference, October 4-7, Saint-Louis, Missouri, USA, 2009, p 1151-1156

F. Delloro, M. Faessel, H. Proudhon, D. Jeulin, M. Jeandin, E. Meillot, and L. Bianchi, A Morphological Approach to the Modeling of the Cold Spray Process, in Proceedings of the International Thermal Spray Conference (ITSC) 2014, 21-23 May, Barcelona, DVS, 2014, p 221-226

B. Yildirim and S. Müftü, Simulation and Analysis of the Impact of Micron-Scale Particles onto a Rough Surface, Int. J. Solids Struct., 2012, 49, p 1375-1386

G. Johnson, Material Characterization for Warhead Computations, Prog. Astronaut. Aeronaut., 1993, 155, p 165-197

E. Auroux, M. Boustie, and J.P. Romain, Improvement of the Laser Spallation Technique Using an Amplifying Layer. Experimental and Numerical Approach, in Shock Compression of Condensed Matter, 1999, M.D. Furnish, L.C. Cjhabildas, and R.S. Hixson, Ed., AIP, 2000, p 1211-1214

M. Arrigoni, M. Jeandin et al., Shock Mechanics and Interfaces, A Full Chapter (Chapter 7), Mechanics of Solid Interfaces, M. Braccini and M. Dupeux, Ed., Wiley, Hoboken, 2012, p 211-248

H.L. Costa, M.A.N. Ardila, W.S. Labiapari, W.M. Silva, and J.D.B. de Mello, Effect of Surface Topography on the Dynamics of the Abrasive During Micro-Abrasion, Wear, 2015, 324-325, p 129-139

B.C. Rincon Troconis and G.S. Frankel, Effect of Roughness and Surface Topography on Adhesion of PVB to AA2024-T3 Using the Blister Test, Surf. Coat. Technol., 2013, 236, p 531-539

D. Jeulin, Random Structure Analysis and Modelling by Mathematical Morphology, Invited Lecture, in Proceeding, 5th International Symposium on Continuum Models of Discrete Systems, Nottingham, 14-20 July 1985, A.J.M. Spencer (edition), A.A. Balkema, Rotterdam, 1985, p. 217-226

D. Jeulin, Anisotropic Rough Surface Modelling by Random Morphological Functions, in Proceeding, 4th European Symposium of Stereology (Göteborg, 26-30 August 1985), Acta Stereologica; 6/2, 1987, p. 183-189

D. Jeulin and P. Laurenge, Simulation of Rough Surfaces by Morphological Random Functions, J. Electron Imaging, 1997, 6(1), p 16-30

D. Jeulin, Boolean Random Functions, Extracted from Stochastic Geometry, Spatial Statistics and Random Fields, Models and Algorithms, Chapter 5, 2013, p. 143-169

T.R. Thomas, Rough Surfaces, Longman Group Limited, Harlow, 1983

Q. Blochet, Influence of Substrate Surface Roughness on Cold-Sprayed Coating-Substrate Bond Strength in Aluminum-Based Systems, Ph.D. Thesis, MINES ParisTech, 2015

Acknowledgments

This work was carried out within the “C-SAR” FUI program. The authors would like to thanks all the members of the program consortium, i.e., Airbus Industries Group, Safran Helicopter Engines, Lifco Industrie, APS Coating, UTBM, Dassault Aviation and Trochet, for valuable discussion, and OSEO, “Pôle ASTech Paris Région”, “Pôle des microtechniques” and “Pôle Pégase” for financial support. Many thanks also to Mrs. N. De Dave-Fabrègue from MINES ParisTech for its precious help in microscopic characterization and metallographic samples preparation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Blochet, Q., Delloro, F., N’Guyen, F. et al. Effect of the Cold-Sprayed Aluminum Coating-Substrate Interface Morphology on Bond Strength for Aircraft Repair Application. J Therm Spray Tech 26, 671–686 (2017). https://doi.org/10.1007/s11666-017-0548-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0548-3