Abstract

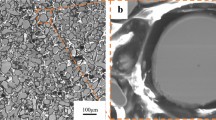

Amorphous coating technology is an attractive way of taking advantage of the superior properties of amorphous alloys for structural applications. However, the limited bonds between splats within the plasma-sprayed coatings result in a typically lamellar and porous coating structure. To overcome these limitations, the as-sprayed coating was treated by a laser-remelting process. The microstructure and phase composition of two coatings were analyzed using scanning electron microscopy with energy-dispersive spectroscopy, transmission electron microscopy, and x-ray diffraction. The wear resistance of the plasma-sprayed coating and laser-remelted coating was studied comparatively using a pin-on-disc wear test under dry friction conditions. It was revealed that the laser-remelted coating exhibited better wear resistance because of its defect-free and amorphous-nanocrystalline composited structure.

Similar content being viewed by others

References

M.M. Trexler and N.N. Thadhani, Mechanical Properties of Bulk Metallic Glasses, Prog. Mater. Sci., 2010, 55, p 759-839

W.H. Wang, C. Dong, and C.H. Shek, Bulk Metallic Glasses, Mater. Sci. Eng. R: Rep., 2004, 44, p 45-90

W.L. Johnson, Bulk Glass-Forming Metallic Alloys: Science and Technology, MRS Bull., 1999, 24, p 42-56

J. Schroers, Processing of Bulk Metallic Glass, Adv. Mater., 2010, 22, p 1566-1597

Y. He, R.B. Schwarz, and J.I. Archuleta, Bulk Glass Formation in the Pd-Ni-P System, Appl. Phys. Lett., 1996, 69, p P1861-P1863

Y.J. Sun, D.D. Qu, Y.J. Huang, K.D. Liss, X.S. Wei, D.W. Xing, and J. Shen, Zr-Cu-Ni-Al Bulk Metallic Glasses with Superior Glass-Forming Ability, Acta Mater., 2009, 57, p 1290-1299

Q.S. Zhang, W. Zhang, and A. Inoue, Ni-free Zr-Fe-Al-Cu Bulk Metallic Glasses with High Glass-Forming Ability, Scr. Mater., 2009, 61, p 241-244

B. Huang, H.Y. Bai, and W.H. Wang, Unique Properties of CuZrAl Bulk Metallic Glasses Induced by Microalloying, J. Appl. Phys., 2011, 110, p 123522

P. Jia, H. Guo, Y. Li, J. Xu, and E. Ma, A new Cu-Hf-Al Ternary Bulk Metallic Glass with High Glass-Forming Ability and Ductility, Scr. Mater., 2006, 54, p 2165-2168

Q. Zheng, H. Ma, E. Ma, and J. Xu, Mg-Cu-(Y, Nd) Pseudo-Ternary Bulk Metallic Glasses: The Effects of Nd on Glass-Forming Ability and Plasticity, Scr. Mater., 2006, 55, p 541-544

E.S. Park, H.G. Kang, W.T. Kin, and D.H. Kim, Effect of Ag Addition on the Glass-Forming Ability of Mg-Cu-Y Metallic Glass Alloys, J. Non-Cryst. Solids, 2001, 279, p 154-160

S.J. Pang, T. Zhang, K. Asami, and A. Inoue, Synthesis of Fe-Cr-Mo-C-B-P Bulk Metallic Glasses with High Corrosion Resistance, Acta Mater., 2002, 50, p 489-497

Q. Li, J. Li, P. Gong, K. Yao, J. Gao, and H. Li, Formation of Bulk Magnetic Ternary Fe80P13C7 Glassy Alloy, Intermetallics, 2012, 26, p 62-65

J.H. Na, M.D. Demetriou, M. Floyd, A. Hoff, G.R. Garrett, and W.L. Johnson, Compositional Landscape for Glass Formation in Metal Alloys, PNAS, 2014, 111, p 9031-9036

Y. Zeng, N. Nishiyama, and A. Inoue, Formation of a Ni-Based Glassy Alloy in Centimeter Scale, Mater. Trans., 2007, 48, p 1355-1358

J. Wang, R. Li, R. Xiao, and T. Xu, Compressibility and Hardness of Co-Based Bulk Metallic Glass: A Combined Experimental and Density Functional Theory Study, Appl. Phys. Lett., 2011, 99, p 151911

Q. Man, H. Sun, Y. Dong, B. Shen, H. Kimura, A. Makino, and A. Inoue, Enhancement of Glass-Forming Ability of CoFeBSiNb Bulk Glassy Alloys with Excellent Soft-Magnetic Properties and Superhigh Strength, Intermetallics, 2010, 18, p 1876-1879

T. Zhang and A. Inour, Bulk Glassy Alloys with Low Liquidus Temperature in Pt-Cu-P System, Mater. Trans., 2003, 44, p 1143-1146

W. Zhang, H. Guo, M.W. Chen, Y. Saotome, C.L. Qin, and A. Inoue, New Au-Based Bulk Glassy Alloys with Ultralow Glass Transition Temperature, Scr. Mater., 2009, 61, p 744-747

M.I. Ojovan and W.B.E. Lee, Connectivity and Glass Transition in Disordered Oxide Systems, J. Non-Cryst. Solids, 2010, 356(44-49), p 2534-2540

C. Suryanarayana, Non-equilibrium Processing of Materials, Pergamon, New York, 1999

K. Miyoshi and D.H. Buckley, Microstructure and Surface Chemistry of Amorphous Alloys Important to Their Friction and Wear Behavior, Wear, 1986, 110, p 295-313

Kishore, U. Sudarsan, N. Chandran, and K. Chattopadhyay, On the Wear Mechanism of Iron and Nickel Based Transition Metal-Metalloid Metallic Glasses, Acta Metall., 1987, 35, p 1463-1473

C.A. Schuh, T.C. Hufnagel, and U. Ramamurty, Mechanical Behavior of Amorphous Alloys, Acta Mater., 2007, 55, p 4067-4109

E. Axinte, Metallic Glasses from “Alchemy” to Pure Science: Present and Future of Design, Processing and Applications of Glassy Metals, Mater. Des., 2012, 35, p 518-556

F. Abdeljawad, M. Fontus, and M. Haataja, Ductility of Bulk Metallic Glass Composites: Microstructural Effects, Appl. Phys. Lett., 2011, 98, p 031909-1-3

J.B. Cheng, X.B. Liang, Z.H. Wang, and B.S. Xu, Dry Sliding Friction and Wear Properties of Metallic Glass Coating and Martensite Stainless Coating, Tribol. Int., 2013, 60, p 140-146

H. Miura, S. Isa, and K. Omuro, Production of Amorphous Iron-Nickel Based Alloys by Flame-Spray Quenching and Coatings on Metal Substrates, Mater. Trans. Jim., 1984, 25, p 284-291

V. Varadaraajan, R.K. Guduru, and P.S. Mohanty, Synthesis and Microstructural Evolution of Amorphous/Nanocrystalline Steel Coatings by Different Thermal Spray Processes, J. Therm. Spray Technol., 2013, 22, p 452-462

B. Movahedi, M.H. Enayati, and C.C. Wong, Structural and Thermal Behavior of Fe-Cr-Mo-P-B-C-Si Amorphous and Nanocrystalline HVOF Coatings, J. Therm. Spray Technol., 2010, 19, p 1093-1099

S. Yugeswaran and A. Kobayashi, Metallic Glass Coatings Fabricated by Gas Tunnel Type Plasma Spraying, Vacuum, 2014, 11, p 177-182

A. Kobayashi, S. Yano, H. Kimura, and A. Inoue, Fe-Based Metallic Glass Coatings Produced by Smart Plasma Spraying Process, Mater. Sci. Eng. B, 2008, 148, p 110-113

D.T.A. Matthews, V. Ocelík, D. Branagan, and J.Th.M. de Hosson, Laser Engineered Surfaces from Glass Forming Alloy Powder Precursors: Microstructure and Wear, Surf. Coat. Technol., 2009, 2039, p 1833-1843

D.T.A. Matthews, V. Ocelík, and J.Th.M. de Hosson, Tribological and Mechanical Properties of High Power Laser Surface-Treated Metallic Glasses, Mater. Sci. Eng. A, 2007, 471, p 155-164

S. Katakam, J.Y. Hwang, S. Paital, R. Banerjee, H. Vora, and N.B. Dahotre, In Situ Laser Synthesis of Fe-Based Amorphous Matrix Composite Coating on Structural Steel, Metall. Mater. Trans. A, 2012, 43, p 4957-4966

E. Foroozmehr and R. Kovacevic, Thermo-Kinetic Modeling of Phase Transformation in Laser Powder Deposition, Metall. Mater. Trans. A, 2009, 40, p 1935-1943

S. Katakam, S. Santhanakrishnan, and N.B. Dahotre, Fe-Based Amorphous Coatings on AISI, 4130 Structural Steel for Corrosion Resistance, Process. Technol., 2012, 64, p 1247-1259

W.W. Liu, X. Lin, G.L. Yang, H.O. Yang, W.D. Huang, and J.F. Li, Crystallization Behavior of Amorphous Heat Affected Zone of Zr55Al10Ni5Cu30 Alloy by Pulse Laser Remelting, Chin. J. Lasers, 2010, 37, p 2104-2111

D.J. Branagan, M. Breitsameter, B.E. Meacham, and V. Belashchenko, High Performance Nanoscale Composite Coatings for Boiler Applications, J. Therm. Spray Technol., 2005, 14, p 196-204

X.B. Zhao and Z.H. Ye, Microstructure and Wear Resistance of Molybdenum Based Amorphous Nanocrystalline Alloy Coating Fabricated by Atmospheric Plasma Spraying, Surf. Coat. Technol., 2013, 228, p 266-270

Z.S. Li, Z.D. Liu, Y.T. Wang, and Y. Wang, Fe-Based Amorphous Composite Coating Prepared by Plasma Remelting, Adv. Mater. Sci. Eng., 2015, 2015, p 1-6

A. Edrisy, T. Perry, Y.T. Cheng, and A.T. Alpas, Wear of Thermal Spray Deposited Low Carbon Steel Coatings on Aluminum Alloys, Wear, 2001, 251, p 1023-1033

A. Edrisy, T. Perry, and A.T. Alpas, Wear Mechanism Maps for Thermal-Spray Steel Coatings, Metall. Mater. Trans. A, 2005, 36A, p 2737-2750

G. Bolelli, B. Bonferroni, J. Laurila, L. Lusvarghi, A. Milanti, K. Niemi, and P. Vuoristo, Micromechanical Properties and Sliding Wear Behaviour of HVOF-Sprayed Fe-Based Alloy Coatings, Wear, 2012, 276-277, p 29-47

S.H. Yoon, J.H. Kim, B.D. Kim, and C.H. Lee, Tribological Behavior of B4C Reinforced Fe-Based Bulk Metallic Glass Composite Coating, Surf. Coat. Technol., 2010, 205, p 1962-1968

T. Fu, F.X. Ye, H.H. Wei, and L. Cui, Laser Surface Remelting of Fe-Based Alloy Coating Deposited by APS, Rare Metal Mater. Eng., 2012, 41(S1), p 407-413

J.C. Huang, J.P. Chu, and J.S.C. Jang, Recent Progress in Metallic Glasses in Taiwan, Intermetallics, 2009, 17, p 973-987

D.J. Branagan, W.D. Swank, D.C. Haggard, and J.R. Fincke, Wear-Resistant Amorphous and Nanocomposite Steel Coatings, Metall. Mater. Trans. A, 2001, 32, p 2615-2621

J.R. Weertman, D. Farkas, K. Hemker, H. Kung, M. Mayo, R. Mitra, and H. Van Swygenhoven, Structure and Mechanical Behavior of Bulk Nanocrystalline Materials, Mater. Res. Soc. Bull., 1999, 24, p 44-50

H. Yoshioka, K. Asami, A. Kawashima, and K. Hashimoto, Laser-Processed Corrosion-Resistant Amorphous NiCrPB Surface Alloys on a Mild Steel, Corros. Sci., 1987, 27, p 981-995

P.L. Zhang, H. Yan, C.W. Yao, Z.G. Li, Z.S. Yu, and P.Q. Xu, Synthesis of Fe-Ni-B-Si-Nb Amorphous and Crystalline Composite Coatings by Lasercladding and Remelting, Surf. Coat. Technol., 2011, 206, p 1229-1236

P. Gargarella, A. Almeida, R. Vilar, and C.S. Kiminami, Formation of Fe-Based Glassy Matrix Composite Coatings by Laser Processing, Surf. Coat. Technol., 2014, 240, p 336-343

A. Inoue, Bulk Amorphous and Nanocrystalline Alloys with High Functional Properties, Mater. Sci. Eng. A, 2001, 304, p 1-10

Acknowledgments

This work was supported by Natural Science Foundation of Shaanxi Province of China (2016JM5058, 2016JM5059), Natural Nature Science Foundation of China (51301022) and The Special Fund for Basic Scientific Research of Central Colleges, Chang’an University (310831161005, 310831161018, 310831163401).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, C., Chen, H., Wang, G. et al. Improvements in Microstructure and Wear Resistance of Plasma-Sprayed Fe-Based Amorphous Coating by Laser-Remelting. J Therm Spray Tech 26, 778–786 (2017). https://doi.org/10.1007/s11666-017-0546-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0546-5