Abstract

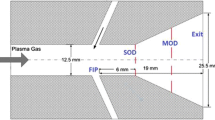

Plasma spray–physical vapor deposition is a new process developed to produce coatings from the vapor phase. To achieve deposition from the vapor phase, the plasma–feedstock interaction inside the plasma torch, i.e., from the powder injection point to the nozzle exit, is critical. In this work, the plasma characteristics and the momentum and heat transfer between the plasma and powder feedstock at different torch input power levels were investigated theoretically to optimize the net plasma torch power, among other important factors such as the plasma gas composition, powder feed rate, and carrier gas. The plasma characteristics were calculated using the CEA2 code, and the plasma–feedstock interaction was studied inside the torch nozzle at low-pressure (20-25 kPa) conditions. A particle dynamics model was introduced to compute the particle velocity, coupled with Xi Chen’s drag model for nonevaporating particles. The results show that the energy transferred to the particles and the coating morphology are greatly influenced by the plasma gas characteristics and the particle dynamics inside the nozzle. The heat transfer between the plasma gas and feedstock material increased with the net torch power up to an optimum at 64 kW, at which a maximum of ~3.4% of the available plasma energy was absorbed by the feedstock powder. Experimental results using agglomerated 7-8 wt.% yttria-stabilized zirconia (YSZ) powder as feedstock material confirmed the theoretical predictions.

Similar content being viewed by others

References

X. Wang, S. Guo, L. Zhao, Y. Zhu, and L. Ai, A Novel Thermal Barrier Coating for High Temperature Applications, Ceram. Int., 2016, 42, p 2648-2653

G. Mauer, M.O. Jarligo, S. Rezanka, A. Hospach, and R. Vaßen, Novel Opportunities for Thermal Spray by PS–PVD, Surf. Coat. Technol., 2015, 268, p 52-57

G. Mauer, A. Hospach, and R. Vaßen, Process Development and Coating Characteristics of Plasma Spray-PVD, Surf. Coat. Technol., 2013, 220, p 219-224

C. Li, H. Guo, L. Gao, L. Wei, S. Gong, and H. Xu, Microstructures and Mechanical Properties of Yttria-Stabilized Zirconia Coatings by Plasma Spray–Physical Vapor Deposition, Ceram. Int., 2015, 41, p 8305-8311

M. Goral, S. Kotowski, A. Nowotnik, M. Pytel, M. Drajewicz, and J. Sieniawski, PS–PVD: Deposition of Thermal Barrier Coatings, Surf. Coat. Technol., 2013, 237, p 51-55

C. Li, H. Guo, L. Gao, L. Wei, S. Gong, and H. Xu, Microstructures of Yttria-Stabilized Zirconia Coatings by Plasma Spray–Physical Vapor Deposition, J. Therm. Spray Technol., 2014, 24(5), p 534-541

J.L. Dorier, M. Gindrat, C. Hollenstein, M. Loch, A. Refke, A. Salito, and G. Barbezat, Plasma Jet Properties in a New Process at Low Pressure for Large Area Thin Film Deposition, International Thermal Spray Conference, ed. by K.A. Khor, E.F. Lugscheider (Singapore, 2001), pp. 759-764

A. Refke, D. Hawley, J. Doesburg, and R. Schmid, LPPS Thin Film Technology for the Application of TBC Systems, International Thermal Spray Conference, ed. by E.F. Lugscheider (Basel, DVS, Dusseldorf, 2005)

K.V. Niessen, M. Gindrat, and A. Refke, Vapor Phase Deposition Using Plasma Spray-PVD, J. Therm. Spray Technol., 2010, 19(1-2), p 502-509

K.V. Niessen and M. Gindrat, Plasma Spray-PVD: A New Thermal Spray Process to Deposit Out of the Vapor Phase, J. Therm. Spray Technol., 2011, 20(4), p 736-743

Q. Chen, X.Z. Peng, G.J. Yang, C.X. Li, and C.J. Li, Characterization of Plasma Jet in Plasma Spray–Physical Vapor Deposition of YSZ Using a <80 kW Shrouded Torch Based on Optical Emission Spectroscopy, J. Therm. Spray Technol., 2015, 24(5), p 1038-1045

Q.Y. Chen, C.X. Li, J.Z. Zhao, G.J. Yang, and C.J. Li, Microstructure of YSZ Coatings Deposited by PS–PVD Using 45 kW Shrouded Plasma Torch, Mater. Manuf. Processes, 2016, 31, p 1183-1191

X. Chen, The Drag Force Acting on a Spherical Non-evaporating or Evaporating Particle Immersed Into a Rarefied Plasma Flow, J. Phys. D Appl. Phys., 1996, 29, p 995

X. Chen and P. He, Heat Transfer from a Rarefied Plasma Flow to a Metallic or Nonmetallic Particle, Plasma Chem. Plasma Process., 1986, 6, p 313-333

S. Gordon and B.J. McBride, Computer Program for Calculation of Complex Chemical Equilibrium Compositions and Applications—Analysis. NASA Ref. Publ., 1994, 1311(1), p 1–64

S. Gordon and B.J. McBride, Computer Program for Calculation of Complex Chemical Equilibrium Compositions and Applications—User’s Manual and Program Description. NASA Ref. Publ., 1996, 1311(2), p 1–43

G. Mauer, Plasma Characteristics and Plasma–Feedstock Interaction Under PS–PVD Process Conditions, Plasma Chem. Plasma Process., 2014, 34, p 1171-1186

X. Chen and X.M. Chen, Drag on a Metallic and Nonmetallic Particle Exposed to a Rarefied Plasma Flow, Plasma Chem. Plasma Process., 1989, 9(3), p 387-408

M. Grujicic, W.S. DeRosset, and D. Helfritch, Flow Analysis and Nozzle Shape Optimization for the Cold Gas Dynamic-Spray Process. J. Eng. Manuf., 2003, 217(B), p 1603–1613

U. Vohrer, H.D. Wiemhöfer, W. Göpel, B.A.V. Hassel, and A.J. Burggraaf, Electronic Properties of Ion Implanted Yttria-Stabilized Zirconia, Solid State Ionics, 1993, 59, p 141-149

M.W. Chase, Jr., NIST-JANAF Thermochemical Tables. J. Phys. Chem., Ref. Data, 4th ed., Monograph 9 (1998)

J.D. Anderson, Quasi-One-Dimensional Flow, Modern Compressible Flows with Historical Prospective, D. D. Heiberg and S. Hazlett, McGraw-Hill, New York City, 1982, p 120-135

Acknowledgment

This research is sponsored by the Natural Science Foundation of China (NSFC) under Grant Nos. 51590894, 51425102, and 51231001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anwaar, A., Wei, L., Guo, H. et al. Plasma–Powder Feedstock Interaction During Plasma Spray–Physical Vapor Deposition. J Therm Spray Tech 26, 292–301 (2017). https://doi.org/10.1007/s11666-016-0519-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0519-0