Abstract

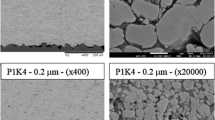

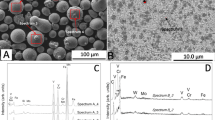

Cold gas spray (CGS) coatings were previously produced by spraying WC-25Co cermet powders onto Al7075-T6 and low-carbon steel substrates. Unlike conventional flame spray techniques (e.g., high-velocity oxy-fuel; HVOF), no melting of the powder occurs; the particles are deformed and bond together after being sprayed by a supersonic jet of compressed gas, thereby building up several layers and forming a coating. WC-Co cermets are used in wear-resistant parts, because of their combination of mechanical, physical, and chemical properties. XRD tests were previously run on the initial powder and the coatings to determine possible phase changes during spraying. The bonding strength of the coatings was measured by adhesion tests. Here, WC-25Co coatings were also deposited on the same substrates by HVOF spraying. The wear resistance and fracture toughness of the coatings obtained previously by CGS and the HVOF coatings obtained here were studied. Their corrosion resistance was determined by electrochemical measurements. It was possible to achieve thick, dense, and hard CGS coatings on Al7075-T6 and low-carbon steel substrates, with better or the same mechanical and electrochemical properties as those of the HVOF coatings; making the former a highly competitive method for producing WC-25Co coatings.

Similar content being viewed by others

References

V.V. Sobolev, J.M. Guilemany, and J. Nutting, High Velocity Oxy-Fuel Spraying, Maney, London, 2004

J.M. Guilemany, S. Dosta, and J.R. Miguel, The Enhancement of the Properties of WC-Co HVOF Coatings Through the Use of Nanostructured and Microstructured Feedstock Powders, Surf. Coat. Technol., 2006, 201, p 1180-1190

J.M. Guilemany, S. Dosta, J. Nin, and J.R. Miguel, Study of the Properties of WC-Co Nanostructured Coatings Sprayed by High-Velocity Oxyfuel, J. Therm. Spray Technol., 2005, 14(3), p 405-413

S. Dosta, M. Couto, and J.M. Guilemany, Cold Spray Deposition of a WC-25Co Cermet Onto Al7075-T6 and Carbon Steel Substrates, Acta Mater., 2013, 61(2), p 643-652

M. Couto, S. Dosta, M. Torrell, J. Fernández, and J.M. Guilemany, Cold Spray Deposition of WC-17 and 12Co cermets onto aluminum, Surf. Coat. Technol., 2013, 235, p 54-61

V.K. Champagne, The Cold Spray Materials Deposition Process: Fundamentals and Applications, CRC Press, Boca Raton, 2007

J. Kawakita, H. Katanoda, M. Watanabe, K. Yokoyama, and S. Kuroda, Warm Spraying: An Improved Spray Process to Deposit Novel Coatings, Surf. Coat. Technol., 2008, 202, p 4369-4373

M.M. Lima, C. Godoy, P.J. Modesi, J.C. Avelar-Batista, A. Davison, and A. Matthews, Coating Fracture Toughness Determined by Vickers Indentation: An Important Parameter in Cavitation Erosion Resistance of WC-Co Thermally Sprayed Coatings, Surf. Coat. Technol., 2004, 177-178, p 489-496

M.M. Lima, C. Godoy, J.C. Avelar-Batista, and P.J. Modesi, Toughness Evaluation of HVOF WC-Co Coatings Using Non-linear Regression Analysis, Mater. Sci. Eng., 2003, A357, p 337-345

E. López Cantera and B.G. Mellor, Fracture Toughness and Crack Morphologies in Eroded WC-Co-Cr Thermally Sprayed Coatings, Mater. Lett., 1998, 37, p 201-210

N. Cinca, M. Barbosa, S. Dosta, and J.M. Guilemany, Study of Ti Deposition Onto Al Alloy by Cold Gas Spraying, Surf. Coat. Technol., 2010, 205, p 1096-1102

C. Verdon, A. Karimi, J.L. Martin, and L. Pawlowski, A Study of High Velocity Oxy-fuel Thermally Sprayed Tungsten Carbide Based Coatings. Part I: Microstructures, Mater. Sci. Eng., 1998, A246, p 11-24

D.A. Stewart, P.H. Shipway, and D.G. McCartney, Abrasive Wear Behavior of Conventional and Nanocomposite HVOF-Sprayed WC-Co Coatings, Wear, 1999, 225-229, p 98-789

T. Schmidt, F. Gärtner, H. Assadi, and H. Kreye, Development of a Generalized Parameter Window for Cold Spray. Deposition, Acta Mater., 2006, 54, p 729-742

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51, p 4379-4394

R.G. Kelly, J.R. Scully, D.W. Shoesmith, and R.G. Buchheit, Electrochemical Techniques in Corrosion Science and Engineering, Chapter 7, Marcel Dekker Inc, New York, 2002

Acknowledgments

The authors wish to thank the University of Barcelona for financial support for this research and the Generalitat de Catalunya for funding project 2009 SGR-00390. Our thanks also go to Fujimi Inc. for providing the WC-Co powder.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Couto, M., Dosta, S., Fernández, J. et al. Comparison of the Mechanical and Electrochemical Properties of WC-25Co Coatings Obtained by High Velocity Oxy-Fuel and Cold Gas Spraying. J Therm Spray Tech 23, 1251–1258 (2014). https://doi.org/10.1007/s11666-014-0123-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0123-0