Abstract

Effects of different concentrations of Cu on the structure, mechanical and corrosion properties of Mg-2%Zn alloy were studied by the use of x-ray diffraction, optical microscopy, scanning electron microscopy, energy dispersive spectroscopy, standard tensile testing, polarization and electrochemical impedance spectroscopy (EIS) measurements. The average grain size of the alloy decreased from above 1000 μm to about 200 μm with 5 wt.% Cu addition in as-cast condition. Microstructural studies revealed that Mg-2Zn-xCu alloys matrix typically consists of primary α-Mg and MgZnCu and Mg(Zn,Cu)2 intermetallics which are mainly found at the grain boundaries. The results obtained from mechanical testing ascertained that Cu addition increased the hardness values significantly. Although the addition of 0.5 wt.% Cu improved the ultimate tensile strength and elongation values, more Cu addition (i.e., 5 wt.%) weakened the tensile properties of the alloy by introducing semi-continuous network of brittle intermetallic phases. Based on polarization test results, it can be concluded that Cu eliminates a protective film on Mg-2%Zn alloy surface. Among Mg-2%Zn-x%Cu alloys, the one containing 0.1 wt.% Cu exhibited the best anti-corrosion property. However, further Cu addition increased the volume fraction of intermetallics culminating in corrosion rate enhancement due to the galvanic couple effect. EIS and microstructural analysis also confirmed the polarization results.

Similar content being viewed by others

References

A.A. Luo, Resent Magnesium Alloy Development for Elevated Temperature Application, Int. Mater. Rev., 2004, 49, p 13–30

D. Orlov, K.D. Ralston, N. Birbilis, and Y. Estrin, Enhanced Corrosion Resistance of Mg Alloy ZK60 After Processing by Integrated Extrusion and Equal Channel Angular Pressing, Acta Mater., 2011, 59, p 6176–6186

P.J. Li, B. Tang, and E.G. Kandalova, Microstructure and Properties of AZ91D Alloy with Ca Additions, Mater. Lett., 2005, 59, p 671–675

H. Sevik, S. Açikgoz, and S.C. Kurnaz, The Effect of Tin Addition on the Microstructure and Mechanical Properties of Squeeze Cast AM60 Alloy, Alloys Compd., 2010, 508, p 110–114

K. Hono, C.L. Mendis, T.T. Sasaki, and K. Oh-ishi, Towards the Development of Heat-Treatable High-Strength Wrought Mg Alloys, Scr. Mater., 2010, 63, p 710–715

J.Y. Lee, H.K. Lim, W.T. Kim, and D.H. Kim, Effect of Al Addition on the Elevated Temperature Deformation Behavior of Mg-Zn-Y Alloy, Mater. Sci. Eng. A, 2008, 487, p 481–487

D.K. Xu, L. Liu, Y.B. Xu, and E.H. Han, Effect of Microstructure and Texture on the Mechanical Properties of the As-Extruded Mg-Zn-Y-Zr Alloys, Mater. Sci. Eng. A, 2007, 443, p 248–256

M. Yamasaki, T. Anan, S. Yoshimoto, and Y. Kawamura, Mechanical Properties of Warm-Extruded Mg-Zn-Gd Alloy With Coherent 14H Long Periodic Stacking Ordered Structure Precipitate, Scr. Mater., 2005, 53, p 799–803

T. Homma, C.L. Mendis, K. Hono, and S. Kamado, Effect of Zr Addition on the Mechanical Properties of As-Extruded Mg-Zn-Ca-Zr Alloys, Mater. Sci. Eng. A, 2010, 527, p 2356–2362

J. Buha, Mechanical Properties of Naturally Aged Mg-Zn-Cu-Mn Alloy, Mater. Sci. Eng. A, 2008, 489, p 127–137

X.H. Shao, Z.Q. Yang, and X.L. Ma, Strengthening and Toughening Mechanisms in Mg-Zn-Y Alloy with a Long Period Stacking Ordered Structure, Acta Mater., 2010, 58, p 4760–4771

G. Ben-Hamu, D. Eliezer, A. Kaya, Y.G. Na, and K.S. Shin, Microstructure and Corrosion Behavior of Mg-Zn-Ag Alloys, Mater. Sci. Eng. A, 2006, 435, p 579–587

G. Ben-Hamu, D. Eliezer, and K.S. Shin, The Role of Si and Ca on New Wrought Mg-Zn-Mn Based Alloy, Mater. Sci. Eng. A, 2007, 447, p 35–43

M. Yamasaki, N. Hayashi, S. Izumi, and Y. Kawamura, Corrosion Behavior of Rapidly Solidified Mg-Zn-Rare Earth Element Alloys in NaCl Solution, Corros. Sci., 2007, 49, p 255–262

W. Unsworth, A New Magnesium Alloy for Automobile Applications, Light Met. Age, 1987, 45, p 10–13

W. Unsworth, SAE Tech. Pap., 1989, 880512, p 1–6

A. Luo and M.O. Pekguleryuz, Cast Magnesium Alloys for Elevated Temperature Applications, Mater. Sci., 1994, 29, p 5259–5266

J. Buha and T. Ohkubo, Natural Aging in Mg-Zn (-Cu) Alloys, Metall. Mater. Trans. A, 2008, 39, p 2259

H.M. Zhu, G. Sha, J.W. Liu, C.L. Wu, C.P. Luo, Z.W. Liu, R.K. Zheng, and S.P. Ringer, Microstructure and mechanical properties of Mg-6Zn-xCu-0.6 Zr (wt.%) alloys, Alloys Compd., 2011, 509, p 3526–3531

H.M. Zhu, C.P. Luo, J.W. Liu, and D.L. Jiao, Growth Twinning Behavior of Cast Mg-Zn-Cu-Zr Alloys, Trans. Nonferr. Met. Soc. China, 2014, 24, p 316–320

H.M. Zhu, C.P. Luo, J.W. Liu, and D.L. Jiao, Effects of Cu Addition on Microstructure and Mechanical Properties of As-Cast Magnesium Alloy ZK60, Trans. Nonferr. Met. Soc. China, 2014, 24, p 605–610

Jing Wang, Ruidong Liu, Tianjiao Luo, and Yuansheng Yang, A High Strength and Ductility Mg-Zn-Al-Cu-Mn Magnesium Alloy, Mater. Des., 2013, 47, p 746–749

S. Golmakaniyoon and R. Mahmudi, Comparison of the Effects of La- and Ce-Rich Rare Earth Additions on the Microstructure, Creep Resistance, and High-Temperature Mechanical Properties of Mg-6Zn-3Cu Cast Alloy, Mater. Sci. Eng. A, 2011, 528, p 5228–5233

J.H. Jun, J.M. Kim, B.K. Park, K.T. Kim, and W.J. Jung, Effects of Rare Earth Elements on Microstructure and High Temperature Mechanical Properties of ZC63 Alloy, Mater. Sci., 2005, 40, p 2659–2661

Y.C. Lee, A.K. Dahle, and D.H. StJohn, The Role of Solute in Grain Refinement of Magnesium, Metall. Mater. Trans. A, 2000, 31, p 2895

A. Becerra and M. Pekguleryuz, Effects of Zinc, Lithium, and Indium on the Grain Size of Magnesium, Mater. Res., 2009, 24, p 1722–1729

H. Okamoto, Comment on Mg-Zn (Magnesium-Zinc), Phase Equilibria Diffus., 1994, 15, p 129–130

Y. Song, E.H. Han, D. Shan, C.D. Yim, and B.S. You, The Effect of Zn Concentration on the Corrosion Behavior of Mg-xZn Alloys, Corros. Sci., 2012, 65, p 322–330

Lu Cheng, Zhang Shuai, Zhang Yu, Zhou Da-Wei, He Chao-Zheng, and Lu Zhi-Wen, Insights into Structural and Thermodynamic Properties of the Intermetallic Compound in Ternary Mg-Zn-Cu Alloy Under High Pressure and High Temperature, Alloys Compd., 2014, 597, p 119–123

N.J. Petch, J. Iron Steel Inst., 1953, 174, p 25–26

E.O. Hall, Proc. Phys. Soc. B, 1951, 64, p 747–753

Y. Lu, Q. Wang, X. Zeng, W. Ding, C. Zhai, and Y. Zhu, Effects of Rare Earths on the Microstructure, Properties and Fracture Behavior of Mg-Al Alloys, Mater. Sci. Eng. A, 2000, 278, p 66–76

Y.Z. Lu and Q.D. Wang, Effects of Silicon on Microstructure, Fluidity, Mechanical Properties, and Fracture Behaviour of Mg-6Al Alloy, Mater. Sci. Technol., 2001, 17, p 207

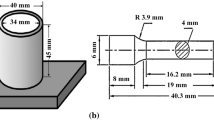

Z.M. Shi and A. Atrens, An Innovative Specimen Configuration for the Study of Mg Corrosion, Corros. Sci., 2011, 53, p 226–246

G. Song, A. Atrens, D. St, J. John, and Y.Li Nairn, The Electrochemical Corrosion of Pure Magnesium in 1 N NaCl, Corros. Sci., 1997, 39, p 855–875

Y. Song, E.H. Han, D. Shan, C.D. Yim, and B.S. You, The Role of Second Phases in the Corrosion Behavior of Mg-5Zn Alloy, Corros. Sci., 2012, 60, p 238–245

Y. Wang, M. Wei, J.C. Gao, J.Z. Hu, and Y. Zhang, Corrosion Process of Pure Magnesium in Simulated Body Fluid, Mater. Lett., 2008, 62, p 2181–2184

S. Cai, T. Lei, N. Li, and F. Feng, Effects of Zn on Microstructure, Mechanical Properties and Corrosion Behavior of Mg-Zn Alloys, Mater. Sci. Eng. C, 2012, 32, p 2570–2577

M. Liu, P. Schmutz, P.J. Uggowitzer, G.L. Song, and A. Atrens, Corros. Sci., 2010, 52, p 3687–3701

Acknowledgments

The authors gratefully acknowledge University of Tehran for financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lotfpour, M., Emamy, M., Dehghanian, C. et al. Influence of Cu Addition on the Structure, Mechanical and Corrosion Properties of Cast Mg-2%Zn Alloy. J. of Materi Eng and Perform 26, 2136–2150 (2017). https://doi.org/10.1007/s11665-017-2672-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2672-0