Abstract

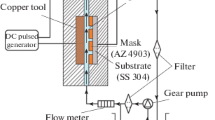

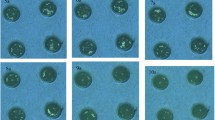

Surface coating and surface texture play a significant role in enhancing the tribological properties of mechanical components. In this study, to further improve the tribological properties of a chrome-coated surface, arrays of circular- and square-shaped micro-dimples were generated on chrome-coated surfaces via electrochemical machining. Through-mask electrochemical micromachining (TMEMM) is a popular electrochemical micromachining method for generating micro-dimple arrays. However, photolithography is a necessary process in conventional TMEMM before electrochemical micromachining, which is time-consuming and expensive when used in mass production. A reusable polydimethylsiloxane mask was introduced to prepare the micro-dimples. Circular micro-dimples of 120 μm diameter and square micro-dimples of 106 μm side length were fabricated on a chrome-coated surface. The results of friction tests indicated that at a load of 220 N, 10 μm deep micro-dimples reduced the coefficient of friction (CoF) significantly compared to an untextured surface. At a load of 320 and 420 N, the CoF continually decreased when the depth of the micro-dimples was increased from 0 to 20 μm. In addition, the results showed that, compared to circular micro-dimples, square micro-dimples contributed to a higher friction reduction ratio under the same conditions. The best friction reduction ratio was found for square dimples with a depth of 20 μm.

Similar content being viewed by others

References

Y. Wang, X. Ma, G. Tang, and M. Sun, Characterization of DLC Films Prepared by Plasma-Based Ion Implantation on AISI, 321 Steel, Vacuum, 2013, 89, p 74–77

U. Sudeep, R.K. Pandey, and N. Tandon, Effects of Surface Texturing on Friction and Vibration Behaviors of Sliding Lubricated Concentrated Point Contacts Under Linear Reciprocating Motion, Tribol. Int., 2013, 62, p 198–207

I. Etsion, State of the Art in Laser Surface Texturing, J. Tribol., 2005, 127(1), p 248–253

L. Ceschini and F. Rotundo, Sliding Contacts for the Pharmaceutical Industry: Failure Analysis and Dry Sliding Tests for the Replacement of Hard Cr on AISI, 316L Steel, Tribol. Int., 2015, 81, p 248–257

S. Xu, X. Gao, M. Hu, J. Sun, and D. Jiang, Nanostructured WS2-Ni Composite Films for Improved Oxidation, Resistance and Tribological Performance, Appl. Surf. Sci., 2014, 288, p 15–25

N.P. Wasekar and G. Sundararajan, Sliding Wear Behavior of Electrodeposited Ni-W Alloy and Hard Chrome Coatings, Wear, 2015, 342, p 340–348

G. Bolelli, V. Cannillo, L. Lusvarghi, and S. Ricco, Mechanical and Tribological Properties of Electrolytic Hard Chrome and Hvof-Sprayed Coatings, Surf. Coat. Tech., 2006, 200(9), p 2995–3009

H.L. Costa and I.M. Hutchings, Hydrodynamic Lubrication of Textured Steel Surfaces Under Reciprocating Sliding Conditions, Tribol. Int., 2007, 40(8), p 1227–1238

M. Wakuda, Y. Yamauchi, S. Kanzaki, and Y. Yasuda, Effect of Surface Texturing on Friction Reduction Between Ceramic and Steel Materials Under Lubricated Sliding Contact, Wear, 2003, 254(3–4), p 356–363

Z. Wang, M. Zhou, and Y. Xu, The Study of Micro-Grating and Micro-Square-Column on Frictional Resistance Reduction of 316L Stainless Steel Surface, J. Inorg. Organomet. Polym., 2013, 23(4), p 803–807

M. Nakano, K. Miyake, A. Korenaga, S. Sasaki, and Y. Ando, Tribological Properties of Patterned NiFe-Covered Si Surfaces, Tribol. Lett., 2009, 35(2), p 133–139

J.W. Byun, H.S. Shin, M.H. Kwon, B.H. Kim, and C.N. Chu, Surface Texturing by Micro ECM for Friction Reduction, Int. J. Precis. Eng. Manuf., 2010, 11(5), p 747–753

H.L. Costa and I.M. Hutchings, Development of a Maskless Electrochemical Texturing Method, J. Mater. Process. Technol., 2009, 209(8), p 3869–3878

C. Madore, O. Piotrowski, and D. Landolt, Through-mask Electrochemical Micromachining of Titanium, J. Electrochim. Soc., 1999, 146(7), p 2526–2532

P. Kern, J. Veh, and J. Michler, New Developments in Through-mask Electrochemical Micromachining of Titanium, J. Micromech. Microeng., 2007, 17(6), p 2526–2532

M. Datta and D. Landolt, Fundamental Aspects and Applications of Electrochemical Microfabrication, Electrochim. Acta, 2000, 45, p 2535–2558

D. Zhu, N.S. Qu, H.S. Li, Y.B. Zeng, D.L. Li, and S.Q. Qian, Electrochemical Micromachining of Microstructures of Micro Hole and Dimple Array, CIRP Ann.-Manuf. Technol., 2009, 58(1), p 177–180

A. Arslan, H.H. Masjuki, M. Varman, M.A. Kalam, and M.M. Quazi, Effects of Texture Diameter and Depth on the Tribological Performance of DLC Coating Under Lubricated Sliding Condition, Appl. Surf. Sci., 2015, 365, p 1135–1149

D. Yan, N. Qu, H. Li, and X. Wang, Significance of Dimple Parameters on the Friction of Sliding Surfaces Investigated by Orthogonal Experiments, Tribol. Trans., 2010, 53(5), p 703–712

L. Galda, P. Pawlus, and J. Sep, Dimples Shape and Distribution Effect on Characteristics of Stribeck Curve, Tribol. Int., 2009, 42(10), p 1505–1512

X.L. Chen, N.S. Qu, H.S. Li, and D. Zhu, The Fabrication and Application of a PDMS Micro Through-holes Mask in Electrochemical Micromanufacturing, Adv. Mech. Eng., 2014, 6, p 943092

Y. Kligerman, I. Etsion, and A. Shinkarenko, Improving Tribological Performance of Piston Rings by Partial Surface Texturing, J. Tribol.-T. ASME, 2005, 127(3), p 632–638

X. Chen, N. Qu, H. Li, and Z. Xu, Pulsed Electrochemical Micromachining for Generating Micro-Dimple Arrays on a Cylindrical Surface with a Flexible Mask, Appl. Surf. Sci., 2015, 343, p 141–147

X.L. Wang, W. Liu, F. Zhou, and D. Zhu, Preliminary Investigation of the Effect of Dimple Size on Friction in Line Contacts, Tribol. Int., 2009, 42(7), p 1118–1120

X.L. Wang, K. Kato, K. Adachi, and K. Aizawa, Loads Carrying Capacity Map For the Surface Texture Design of SiC Thrust Bearing Sliding in Water, Tribol. Int., 2003, 36(3), p 189–197

I. Etsion, Y. Kligerman, and G. Halperin, Analytical and Experimental Investigation of Laser-Textured Mechanical Seal Faces, Tribol. Trans., 1999, 42(3), p 511–516

K.H. Zum Gahr, R. Wahl, and K. Wauthier, Experimental Study of the Effect of Microtexturing on Oil Lubricated Ceramic/Steel Friction Pairs, Wear, 2009, 267(5–8), p 1241–1251

B. Podgornik, L.M. Vilhena, M. Sedlacek, Z. Rek, and I. Zun, Effectiveness and Design of Surface Texturing for Different Lubrication Regimes, Meccanica, 2012, 47(7), p 1613–1622

H. Yu, W. Huang, and X. Wang, The Effect of Dimple Shapes on Friction of Parallel Surfaces, Proc. Inst. Mech. Eng. J-J. Eng. Tribol., 2011, 225(J8), p 693–703

Acknowledgments

The work described in this study was supported by the National Basic Research Program of China (973 Program, Grant 2015CB057502) and the Fundamental Research Funds for the Central Universities (Grant NZ2016106).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, X., Qu, N., Hou, Z. et al. Friction Reduction of Chrome-Coated Surface with Micro-Dimple Arrays Generated by Electrochemical Micromachining. J. of Materi Eng and Perform 26, 667–675 (2017). https://doi.org/10.1007/s11665-017-2501-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2501-5