Abstract

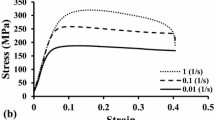

The processing map and microstructure evolution of Ni-18.3Cr-6.4Co-5.9W-4Mo superalloy were investigated in the temperature range of 1010-1160 °C and strain rate range of 0.001-1 s−1 by means of hot compression tests. According to the processing map, the optimum processing parameters were located in the temperature range of 1100-1160 °C and strain rate range of 0.01-0.3 s−1. The carbides in the alloy contributed to form a fine grain microstructure. In addition, four different instability criteria of Prasad, Gegel, Malas, and Murty were used to predict the unstable domains in the processing map. Meanwhile, the microstructure observations revealed that the unstable domain predicted by Murty’s instability criterion was very effective at high strain rate, which was the best choice for the studied alloy. Furthermore, the electron backscattered diffraction technique was used to detect the Σ3 boundaries and the adiabatic shear bands in the alloy. The results revealed that the fractions of Σ3 boundaries in the alloy deformed at 1100 °C/0.01 s−1 and 1160 °C/0.1 s−1 reached about 25 and 27%, respectively. Meanwhile, the fraction of low-angle grain boundaries and dislocation density were relatively high in the adiabatic shear band.

Similar content being viewed by others

References

H. Zhang, K. Zhang, H. Zhou, Z. Lu, C. Zhao, and X. Yang, Effect of Strain Rate on Microstructure Evolution of a Nickel-Based Superalloy During Hot Deformation, Mater. Des., 2015, 80, p 51–62

H. Zhang, K. Zhang, Z. Lu, C. Zhao, and X. Yang, Hot Deformation Behavior and Processing Map of a γ′-Hardened Nickel-Based Superalloy, Mater. Sci. Eng.: A, 2014, 604, p 1–8

N. Park, I. Kim, Y. Na, and J. Yeom, Hot Forging of a Nickel-Base Superalloy, J. Mater. Process. Technol., 2001, 111, p 98–102

R. Raj, Development of a Processing Map for Use in Warm-Forming and Hot-Forming Processes, Metall. Trans. A, 1981, 12, p 1089–1097

H. Gegel, J. Malas, S. Doraivelu, and V. Shende, Metals Hand Book, Vol 14, American Society of Metals, Metals Park, OH, 1987, p 417

M. Xiong, Z. Weidong, S. Yu, Z. Yongqing, W. Shaoli, and Z. Yigang, A Comparative Study of Various Flow Instability Criteria in Processing Map, Rare Metal Mater. Eng., 2010, 39, p 756–761

Y. Prasad and T. Seshacharyulu, Modelling of Hot Deformation for Microstructural Control, Int. Mater. Rev., 1998, 43, p 243–258

S. Murty and B.N. Rao, On the Development of Instability Criteria During Hotworking with Reference to IN 718, Mater. Sci. Eng., 1998, 254, p 76–82

S. Murty, B.N. Rao, and B. Kashyap, Improved Ductile Fracture Criterion for Cold Forming of Spheroidised Steel, J. Mater. Process. Technol., 2004, 147, p 94–101

Y. Prasad, H. Gegel, S. Doraivelu, J. Malas, J. Morgan, K. Lark, and D. Barker, Modeling of Dynamic Material Behavior in hot Deformation: Forging of Ti-6242, Metall. Trans. A, 1984, 15, p 1883–1892

J.C. Malas and V. Seetharaman, Using Material Behavior Models to Develop Process Control Strategies, JOM, 1992, 44, p 8–13

A. Amiri, M. Sadeghi, and G. Ebrahimi, Characterization of Hot Deformation Behavior of AMS 5708 Nickel-Based Superalloy Using Processing Map, J. Mater. Eng. Perform., 2013, 22, p 3940–3945

Y. Ning, Z. Yao, H. Li, H. Guo, Y. Tao, and Y. Zhang, High Temperature Deformation Behavior of Hot Isostatically Pressed P/M FGH4096 Superalloy, Mater. Sci. Eng., 2010, 527, p 961–966

Q. Pan, B. Li, Y. Wang, Y. Zhang, and Z. Yin, Characterization of Hot Deformation Behavior of Ni-Base Superalloy Rene’41 Using Processing Map, Mater. Sci. Eng., 2013, 585, p 371–378

D.-X. Wen, Y.C. Lin, H.-B. Li, X.-M. Chen, J. Deng, and L.-T. Li, Hot Deformation Behavior and Processing Map of a Typical Ni-Based Superalloy, Mater. Sci. Eng., 2014, 591, p 183–192

Y.C. Lin, D.-G. He, M.-S. Chen, X.-M. Chen, C.-Y. Zhao, X. Ma, and Z.-L. Long, EBSD Analysis of Evolution of Dynamic Recrystallization Grains and δ Phase in a Nickel-Based Superalloy During Hot Compressive Deformation, Mater. Des., 2016, 97, p 13–24

Z. Shi, X. Yan, and C. Duan, Characterization of Hot Deformation Behavior of GH925 Superalloy Using Constitutive Equation, Processing Map and Microstructure Observation, J. Alloys Compd., 2015, 652, p 30–38

D.-X. Wen, Y. Lin, J. Chen, J. Deng, X.-M. Chen, J.-L. Zhang, and M. He, Effects of Initial Aging Time on Processing Map and Microstructures of a Nickel-Based Superalloy, Mater. Sci. Eng., 2015, 620, p 319–332

Y. Kong, P. Chang, Q. Li, L. Xie, and S. Zhu, Hot Deformation Characteristics and Processing Map of Nickel-Based C276 Superalloy, J. Alloys Compd., 2015, 622, p 738–744

P. Zhang, C. Hu, C.-G. Ding, Q. Zhu, and H.-Y. Qin, Plastic Deformation Behavior and Processing Maps of a Ni-Based Superalloy, Mater. Des., 2015, 65, p 575–584

Y.-Q. Ji, S.-D. Qu, and W.-X. Han, Hot Deformation and Processing Map of GH3535 Superalloy, Trans. Nonferrous Metals Soc. China, 2015, 25, p 88–94

D.-G. He, Y. Lin, M.-S. Chen, J. Chen, D.-X. Wen, and X.-M. Chen, Effect of Pre-treatment on Hot Deformation Behavior and Processing Map of an Aged Nickel-Based Superalloy, J. Alloys Compd., 2015, 649, p 1075–1084

F. Chen, J. Liu, H. Ou, B. Lu, Z. Cui, and H. Long, Flow Characteristics and Intrinsic Workability of IN718 Superalloy, Mater. Sci. Eng., 2015, 642, p 279–287

Y.C. Lin, J. Deng, Y.-Q. Jiang, D.-X. Wen, and G. Liu, Hot Tensile Deformation Behaviors and Fracture Characteristics of a Typical Ni-Based Superalloy, Mater. Des., 2014, 55, p 949–957

Y.C. Lin, J. Deng, Y.-Q. Jiang, D.-X. Wen, and G. Liu, Effects of Initial δ Phase on Hot Tensile Deformation Behaviors and Fracture Characteristics of a Typical Ni-Based Superalloy, Mater. Sci. Eng., 2014, 598, p 251–262

D. Li, Q. Guo, S. Guo, H. Peng, and Z. Wu, The Microstructure Evolution and Nucleation Mechanisms of Dynamic Recrystallization in Hot-Deformed Inconel 625 Superalloy, Mater. Des., 2011, 32, p 696–705

H. Jiang, J. Dong, M. Zhang, L. Zheng, and Z. Yao, Hot Deformation Characteristics of Alloy 617B Nickel-Based Superalloy: A Study Using Processing Map, J. Alloys Compd., 2015, 647, p 338–350

S. Guo, D. Li, H. Pen, Q. Guo, and J. Hu, Hot Deformation and Processing Maps of Inconel 690 Superalloy, J. Nucl. Mater., 2011, 410, p 52–58

M.C. Somani, K. Muraleedharan, Y.V.R.K. Prasad, and V. Singh, Mechanical Processing and Microstructural Control in Hot Working of Hot Isostatically Pressed P/M IN-100 Superalloy, Mater. Sci. Eng., 1998, 245, p 88–99

V. Sample, G. Fitzsimons, and A. DeArdo, Dynamic Softening of Copper During Deformation at High Temperatures and Strain Rates, Acta Metall., 1987, 35, p 367–379

D.G. Brandon, The Structure of High-Angle Grain Boundaries, Acta Metall., 1966, 14, p 1479–1484

R.L. Fullman, Formation of Annealing Twins during Grain Growth, J. Appl. Phys., 1950, 22, p 1350–1355

S. Mahajan, C.S. Pande, M.A. Imam, and B.B. Rath, Formation of Annealing Twins in f.c.c. Crystals, Acta Mater., 1997, 45, p 2633–2638

H.Y. Sun, Z.J. Zhou, M. Wang, and L.I. Xiao, Effect of Thermomechanical Parameters on ∑3n Grain Boundaries and Grain Boundary Networks of a New Superaustenitic Stainless Steel, J Iron Steel Res., 2014, 21, p 109–115

Q. Guo, D. Li, S. Guo, H. Peng, and J. Hu, The Effect of Deformation Temperature on the Microstructure Evolution of Inconel 625 Superalloy, J. Nucl. Mater., 2011, 414, p 440–450

R. Doherty, D. Hughes, F. Humphreys, J. Jonas, D.J. Jensen, M. Kassner, W. King, T. McNelley, H. McQueen, and A. Rollett, Current Issues in Recrystallization: A Review, Mater. Today, 1998, 1, p 14–15

H. Zhou, R. Liu, Z. Liu, X. Zhou, Q. Peng, F. Zhong, and Y. Peng, Hot Deformation Characteristics of GH625 and Development of a Processing Map, J. Mater. Eng. Perform., 2013, 22, p 2515–2521

G. Zhou, H. Ding, F. Cao, B. Zhang, A Comparative Study of Various Flow Instability Criteria in Processing Map of Superalloy GH4742, J. Mater. Sci. Technol., 2014, 30, p 217–222

S. Medeiros, Y. Prasad, W.G. Frazier, and R. Srinivasan, Microstructural Modeling of Metadynamic Recrystallization in Hot Working of IN 718 Superalloy, Mater. Sci. Eng., 2000, 293, p 198–207

X. Wang, E. Brünger, and G. Gottstein, The Role of Twinning During Dynamic Recrystallization in Alloy 800H, Scr. Mater., 2002, 46, p 875–880

Y. Wang, L. Zhen, W. Shao, L. Yang, and X. Zhang, Hot Working Characteristics and Dynamic Recrystallization of Delta-Processed Superalloy 718, J. Alloys Compd., 2009, 474, p 341–346

S. Medeiros, Y. Prasad, W.G. Frazier, and R. Srinivasan, Modeling Grain Size During Hot Deformation of IN 718, Scr. Mater., 1999, 42, p 17–23

Y. Wang, W. Shao, L. Zhen, L. Yang, and X. Zhang, Flow Behavior and Microstructures of Superalloy 718 During High Temperature Deformation, Mater. Sci. Eng., 2008, 497, p 479–486

G. Gottstein, Annealing Texture Development by Multiple Twinning in fcc Crystals, Acta Metall., 1984, 32, p 1117–1138

H.-Y. Wu, F.-J. Zhu, S.-C. Wang, W.-R. Wang, C.-C. Wang, and C.-H. Chiu, Hot Deformation Characteristics and Strain-Dependent Constitutive Analysis of Inconel 600 Superalloy, J. Mater. Sci., 2012, 47, p 3971–3981

S.N. Murty and B.N. Rao, On the Flow Localization Concepts in the Processing Maps of Titanium Alloy Ti-24Al-20Nb, J. Mater. Process. Technol., 2000, 104, p 103–109

S. Murty and B.N. Rao, On the Hot Working Characteristics of Inconel Alloy MA 754 Using Processing Maps, Scand. J. Metall., 2000, 29, p 146–150

S.N. Murty, B.N. Rao, and B. Kashyap, On the Hot Working Characteristics of 6061Al-SiC and 6061-Al 2 O 3 Particulate Reinforced Metal Matrix Composites, Compos. Sci. Technol., 2003, 63, p 119–135

S. Narayana Murty, B. Nageswara Rao, and B. Kashyap, Identification of Flow Instabilities in the Processing Maps of AISI, 304 Stainless Steel, J. Mater. Process. Technol, 2005, 166, p 268–278

S. Ramanathan, R. Karthikeyan, and M. Gupta, Development of Processing Maps for Al/SiCp Composite Using Fuzzy Logic, J. Mater. Process. Technol., 2007, 183, p 104–110

C. Yu, D. Hongshuang, Z. Jingqi, M. Tianjun, and Z. Jiecen, Research on Hot Deformation Behavior and Hot Workability of Alloy 800H, Acta Metall. Sin., 2013, 49(7), p 811–821

S. Mandal, M. Jayalakshmi, A. Bhaduri, and V.S. Sarma, Effect of Strain Rate on the Dynamic Recrystallization Behavior in a Nitrogen-Enhanced 316L (N), Metall. Mater. Trans. A, 2014, 45, p 5645–5656

K. Song and M. Aindow, Grain Growth and Particle Pinning in a Model Ni-Based Superalloy, Mater. Sci. Eng., 2008, 479, p 365–372

Acknowledgments

This work has been supported by A Project of Shandong Province Higher Educational Science and Technology Program (No. J12LB03) and Research Foundation for new introduced doctor of Shandong University of Science and Technology.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Qin, S., Liu, J., Zhang, H. et al. The Microstructure Evolution and Processing Map of Ni-18.3Cr-6.4Co-5.9W-4Mo Superalloy During Hot Deformation. J. of Materi Eng and Perform 25, 2489–2499 (2016). https://doi.org/10.1007/s11665-016-2091-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2091-7