Abstract

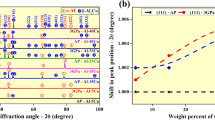

Instrumented indentation tests were performed to study how grain boundaries and solute atoms affect creep and instantaneous plastic deformation in ultrafine-grained (UFG) Al-Mg solid solution alloys with average grain size d = 0.3 − 1.0 μm at T = 373 K. In the results for Al-1.0 mol% Mg, the degree of instantaneous plastic displacement generated with a rapid increase in the load was smaller when the grain diameter was smaller. On the other hand, creep occurs more readily in materials with a smaller grain diameter. When the load was rapidly decreased during creep, the indenter displacement gradually decreased over time. The degree of reverse creep that occurs is greater when the grain diameter is smaller. In light of these test results and reports in the related literature, reverse creep is thought to occur because of inverted movement of piled-up dislocations near the grain boundaries. For the case of Al-xMg (x = 0.5, 1.0, 2.0 mol%), the results show that as the solute concentration increases, the occurrence of instantaneous plastic deformation, creep, and reverse creep becomes less likely. Overall, the results indicate that the plastic deformation behavior obtained by the testing conditions of present study for UFG Al-Mg alloys could be explained based on understanding of the behavior of course-grained materials.

Similar content being viewed by others

References

M.A. Meyers, A. Mishra, and D.J. Benson, Mechanical Properties of Nanocrystalline Materials, Prog. Mater. Sci., 2006, 51, p 427–556

Y.J. Li, X.H. Zeng, and W. Blum, Transition from Strengthening to Softening by Grain Boundaries in Ultrafine-Grained Cu, Acta Mater., 2004, 52, p 5009–5018

P.L. Sun, E.K. Cerreta, G.T. Gray, III, and J.F. Bingert, The Effect of Grain Size, Strain Rate, and Temperature on the Mechanical Behavior of Commercial Purity Aluminum, Metall. Mater. Trans., 2006, 37A, p 2983–2994

N. Ahmed and A. Hartmaier, Mechanism of Grain Boundary Softening and Strain-Rate Sensitivity in Deformation of Ultrafine-Grained Metals at High Temperatures, Acta Mater., 2001, 59, p 4323–4334

H. Takagi, M. Dao, M. Fujiwara, and M. Otsuka, Creep Characterization of Aluminum-Magnesium Solid-Solution Alloy through Self-Similar Microindentation, Mater. Trans., 2006, 47, p 2006–2014

A.K. Mukherjee, An Examination of the Constitutive Equation for Elevated Temperature Plasticity, Mater. Sci. Eng. A, 2002, 322, p 1–22

M.E. Kassner, Fundamentals of Creep in Metals and Alloys, Elsevier, Oxford, 2009

R. Labusch, Statistical Theories of Solid Solution Hardening, Phys. Stat. Sol., 1970, 41, p 659–669

A.S. Argon, Strengthening Mechanisms in Crystal Plasticity, Oxford Materials, Oxford, 2008

A. Ball and M.M. Hutchison, Superplasticity in the Aluminum-Zinc Eutectoid, Met. Sci. J., 1959, 3, p 1–6

F.A. Mohamed and M. Chauhan, Interpretation of the Creep Behavior of Nanocrystalline Ni in Terms of Dislocation Accommodated Boundary Sliding, Met. Mater. Trans. A, 2006, 37, p 3555–3567

F. Mompiou, D. Caillard, M. Legros, and H. Mughrabi, In Situ TEM Observations of Reverse Dislocation Motion upon Unloading in Tensile-Deformed UFG Aluminum, Acta Mater., 2012, 60, p 3402–3414

J. Friedel, Dislocations, Pergamon, Oxford, 1964

P.W. Davies, G. Nelmes, K.R. Williams, and B. Wishire, Stress-Change Experiments during High-Temperature Creep of Copper, Iron, and Zinc, Met. Sci., 1973, 17, p 87–92

J.D. Parker and B. Wilshire, Rate-Controlling Processes during Creep of Super-Purity Aluminum, Philos. Mag. A, 1980, 41, p 665–680

Acknowledgments

The UFG samples were produced using a high-pressure torsion machine in the laboratory of Professor Zenji Horita of Kyushu University. The indentation tests were carried out with the cooperation of Naoki Yamanashi, a graduate student in Nihon University’s College of Engineering. A portion of this study was conducted with the support of a Grant-in-Aid for Scientific Research (No. 23102508).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Takagi, H., Fujiwara, M. Deformation Behavior Immediately After Indentation Load Change in Ultrafine-Grained Al-Mg Solid Solution Alloys. J. of Materi Eng and Perform 25, 2230–2235 (2016). https://doi.org/10.1007/s11665-016-2062-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2062-z