Abstract

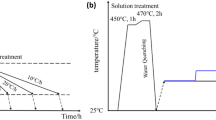

Multi-step heat treatment effectively enhances the stress corrosion cracking (SCC) resistance but usually degrades the mechanical properties of Al-Zn-Mg-Cu alloys. With the aim to enhance SCC resistance as well as strength of Al-Zn-Mg-Cu alloys, we have optimized the process parameters during two-step aging of Al-6.1Zn-2.8Mg-1.9Cu alloy by Taguchi’s L9 orthogonal array. In this work, analysis of variance (ANOVA) was performed to find out the significant heat treatment parameters. The slow strain rate testing combined with scanning electron microscope and transmission electron microscope was employed to study the SCC behaviors of Al-Zn-Mg-Cu alloy. Results showed that the contour map produced by ANOVA offered a reliable reference for selection of optimum heat treatment parameters. By using this method, a desired combination of mechanical performances and SCC resistance was obtained.

Similar content being viewed by others

References

T.D. Burleigh, The Postulated Mechanisms for Stress Corrosion Cracking of Aluminum Alloys—A Review of the Literature 1980-1989, Corros. Sci., 1991, 47, p 89–98

S.P. Knight, N. Birbilis, B.C. Muddle, A.R. Trueman et al., Corrosions Between Intergranular Stress Corrosion Cracking, Grain-Boundary Microchemistry, Grain-Boundary Electrochemistry for Al-Zn-Mg-Cu Alloys, Corros. Sci., 2010, 52, p 4073–4083

L. Lin, Z. Liu, Y. Li, X. Han, and X. Chen, Effect of Severe Cold Rolling on Exfoliation Corrosion Behavior of Al-Zn-Mg-Cu-Cr alloy, J. Mater. Eng. Perform., 2012, 21, p 1070–1075

M.S. Yeh, L.C. Tsao, and T.H. Chuang, Effect of Microstructures on Corrosion and Stress Corrosion Behaviors of an Al-12.1 at% Zn Alloy, J. Mater. Eng. Perform., 2000, 9, p 396–401

D. Najjar, T. Magnin, and T.J. Warner, Influence of Critical Surface Defects and Localized Competition Between Anodic Dissolution and Hydrogen Effects During Stress Corrosion Cracking of a 7050 Aluminum Alloy, Mater. Sci. Eng. A, 1997, 238, p 293–302

R.G. Song, W. Dietzel, B.J. Zhang, W.J. Liu et al., Stress Corrosion Cracking and Hydrogen Embrittlement of an Al-Zn-Mg-Cu Alloy, Acta Mater., 2004, 52, p 4727–4743

M. Dixit, R.S. Mishra, and K.K. Sankaran, Structure-Property Correlation in Al 7055 High Strength Aluminum Alloys, Mater. Sci. Eng. A, 2008, 478, p 163–172

J.C. Lin, H.L. Liao, W.D. Jehng, C.H. Chang, and S.L. Lee, Effect of Heat Treatments on the Tensile Strength and SCC-Resistance of AA70075 in an Alkaline Saline Solution, Corros. Sci., 2006, 48, p 3139–3156

Y. Deng, Z.M. Yin, and Z. Kai, Effect of Sc and Zr Microalloying Additions and Aging Time at 120°C on the Corrosion Behavior of an Al-Zn-Mg Alloy, Corros. Sci., 2012, 65, p 288–298

D. Wang, D.R. Ni, and Z.Y. Ma, Effect of Pre-strain and Two-Step Aging on Microstructure and Stress Corrosion Cracking of 7050 Alloy, Mater. Sci. Eng. A, 2008, 494, p 360–366

A.F. Oliveira, M.C. Jr., D. Barros, K.R. Cardoso, and D.N. Travessa, The Effect of RRA on the Strength and SCC Resistance on AA7050 and AA7150 Aluminium Alloys, Mater. Sci. Eng. A, 2004, 379, p 321–326

X. Fan, D. Jiang, Q. Meng, Z. Lai, and X. Zhang, Characterization of Precipitation Microstructure and Properties of 7150 Aluminum Alloy, Mater. Sci. Eng. A, 2006, 427, p 130–135

Z. Li, B. Xiong, Y. Zhang, B. Zhu et al., Investigation of Microstructural Evolution and Mechanical Properties During Two-Step Ageing Treatment at 115 and 160 °C in an Al-Zn-Mg-Cu Alloy Pre-stretched Thick Plate, Mater. Charact., 2008, 59, p 279–282

R. Roy, Design of Experiments Using the Taguchi Approach, Wiley, New York, 2001

E. Rastkerdar, M. Shamanian, and A. Saatchi, Taguchi Optimization of Pulsed Current GTA Welding Parameters for Improved Corrosion Resistance of 5083 Aluminum Welds, J. Mater. Eng. Perform., 2013, 22, p 1149–1160

C.P. Ferrer, M. Koul, and B.J. Connolly, Improvements in Strength and Stress Corrosion Cracking Properties in Aluminum Alloy 7075 via Low Temperature Retrogression and Re-ageing Heat Treatments, Corros. Sci., 2003, 59, p 520–528

M.J. Starink and X.M. Li, A Model for the Electrical Conductivity of Peak-Aged and Overaged Al-Zn-Mg-Cu Alloys, Metall. Mater. Trans. A, 2003, 34, p 899–911

G.S. Peace, Taguchi Methods: A Hands-On Approach, Addison Wesle, New York, 1993

A.K. Mukhopadhyay, Development of Reproducible and Increased Strength Properties in Thick Extrusions of Low Alloy Al-Zn-Mg-Cu Based AA7075, Metall. Mater. Trans. A, 1997, 28, p 2429–2433

W.F. Smith and N.J. Grant, The Effect of Multiple-Step Aging on the Strength Properties and Precipitate-Free Zone Width in Al-Zn-Mg Alloys, Metall. Trans., 1970, 1, p 979–983

Z. Li, B. Xiong, Y. Zhang, B. Zhu, F. Wang, and H. Liu, Investigation of Microstructural Evolution and Mechanical Properties During Two-Step Ageing Treatment at 115 and 160°C in an Al-Zn-Mg-Cu Alloy Pre-stretched Think Plate, Mater. Charact., 2008, 59, p 278–282

B. Ou, J. Yang, and M. Wei, Effect of Homogenization and Aging Treatment on Mechanical Properties and Stress-Corrosion Cracking of 7050 Alloys, Metall. Mater. Trans. A, 2007, 38, p 1760–1773

D. Wang, Z. Ma, and Z. Gao, Effect of Severe Cold Rolling on Tensile Properties and Stress Corrosion Cracking of 7050 Aluminum Alloy, Mater. Chem. Phys., 2009, 117, p 228–233

D. Wang and Z.Y. Ma, Effect of Pre-strain on Microstructure and Stress Corrosion Cracking of Over-aged 7050 Aluminum Alloy, J. Alloys Compd., 2009, 469, p 445–450

S. Gang and C. Alfred, Early-Stage Precipitation in Al-Zn-Mg-Cu Alloy (7050), Acta Mater., 2004, 52, p 4503–4516

Acknowledgments

The authors would like to acknowledge the financial support provided by the National Key Fundamental Research Project of China and the Fundamental Research Funds for the Central Universities of Central South University (No. 2014zzts017).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, L., Liu, Z., Ying, P. et al. Improved Stress Corrosion Cracking Resistance and Strength of a Two-Step Aged Al-Zn-Mg-Cu Alloy Using Taguchi Method. J. of Materi Eng and Perform 24, 4870–4877 (2015). https://doi.org/10.1007/s11665-015-1733-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1733-5