Abstract

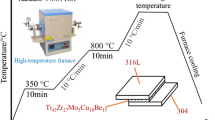

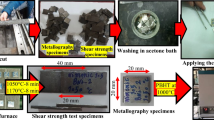

The paper describes a new approach for vacuum brazing of niobium-316L stainless steel transition joints for application in superconducting radiofrequency cavities. The study exploited good wettability of titanium-activated silver-base brazing alloy (CuSil-ABA®), along with nickel as a diffusion barrier, to suppress brittle Fe-Nb intermetallic formation, which is well reported during the established vacuum brazing practice using pure copper filler. The brazed specimens displayed no brittle intermetallic layers on any of its interfaces, but instead carried well-distributed intermetallic particles in the ductile matrix. The transition joints displayed room temperature tensile and shear strengths of 122-143 MPa and 80-113 MPa, respectively. The joints not only exhibited required hermeticity (helium leak rate <1.1 × 10−10 mbar l/s) for service in ultra-high vacuum but also withstood twelve hour degassing heat treatment at 873 K (suppresses Q-disease in niobium cavities), without any noticeable degradation in the microstructure and the hermeticity. The joints retained their leak tightness even after undergoing ten thermal cycles between the room temperature and the liquid nitrogen temperature, thereby establishing their ability to withstand service-induced low cycle fatigue conditions. The study proposes a new lower temperature brazing route to form niobium-316L stainless steel transition joints, with improved microstructural characteristics and acceptable hermeticity and mechanical properties.

Similar content being viewed by others

References

A.R. Jana, V. Kumar, A. Kumar, and R. Gaur, Electromagnetic Design of a 650-MHz Superconducting Radio Frequency Cavity, IEEE Trans. Appl. Supercond., 2013, 23(4), p 3500816

P.K. Nema, Application of Accelerators for Nuclear Systems: Accelerator Driven System (ADS), Energy Procedia, 2011, 7, p 597–608

H. Padamsee, J. Knobloch, and T. Hays, RF Superconductivity for Accelerators, Wiley, New York, NY, 1998

E.A. Brandes and G.B. Brook, Ed., Smithells Metals Reference Book, 7th edn. (Oxford, UK), Butterworth-Heinemann, 2000, p 14.3–14.5

H. Kaiser, Ge Meyer, H.B. Peters, and G. Weichert, Helium Vessel for the TTF Cavity, TESLA 1994-26, DESY, 1994

C. Grimm, T. Arkan, M. Foley, T. Khabiboulline, and D. Watkins, 1.3 GHz RF Nb Cavity to Ti Helium Vessel TIG Welding Process at Fermi Lab, Proc. Int. Conf. SRF2009, 2009 (Berlin), p 669–671

J. Brandt, S. Barbanotti, R. Wands, N. Dhanaraj, T. Khabiboulline, H. Carter, M. Foley, and C. Grimm, SS Helium Vessel Development for 1.3 GHz SRF Cavity at Fermi lab, Proc. Linear Accelerator Conf. LINAC2010, 2010 (Tsukuba), p 596–598

S. Atieh, G. ArnauIzquierdo, S.I. Aviles, O. Capatina, T. Renaglia, T. Tardy, A.N Valverde, and W. Weingarten, Mechanical Design and Fabrication Studies for SPL Superconducting RF Cavities, Proc. Int. Particle Accelerator Conf. IPAC-2011, 2011 (San Sebastián), p 199–201

L. Ristori, M.H. Awida, I. Gonin, M. Merio, D. Passarelli, and V. Yakovlev, Design of SSR1 Spoke Resonators for PXIE, Proc. Int. Particle Accelerator Conf. IPAC-2012, 2012 (LA), p 2342–2344

L. Ristori and W. Toter, Development at ANL of a Copper Brazed Joint for the Coupling of the Niobium Cavity End Wall to the Stainless Steel Helium Vessel in the Fermi Lab SSR1 resonator, Proc. Int. Particle Accelerator Conf. IPAC-2012, 2012 (LA), WEPPC058, p 2345–2347

O. Capatina, S. Atieh, I.A. Santillana, G.A. Izquierdo, R. Bonomi, S. Calatroni, J. Chambrillon, F. Gerigk, R. Garoby, M. Guinchard, T. Junginger, M. Malabaila, L. Marques Antunes Ferreira, S. Mikulas, V. Parma, F. Pillon, T. Renaglia, K. Schirm, T. Tardy, M. Therasse, A. Vacca, N.V. Alonso, and A.V. Craen, CERN Developments for 704 MHz Superconducting Cavities, Proc. 16th Int. Conf. on RF Superconductivity, 2013 (Paris), FRIOB04, p 1192–1205

H. Saugnac, S. Rousselot, C. Commeaux, H. Gassot, T. Junquera, P. Bosland, and H. Safa, Preliminary Design of Stainless Steel Helium Tank and its Associated Cold Tuning System for 700 MHz SCRF Cavities for Proton, Proc. 10th Workshop of RF Superconductivity SRF-2001, 2001 (Tsukuba), p 540–542

A. Kumar, A.R. Jana, and V. Kumar, 2013, A Study of Dynamic Lorentz Force Detuning of 650 MHz βg = 0.9 Superconducting Radiofrequency Cavity, http://arxiv.org/abs/1308.4532, visited on Sept. 4, 2014

P. Sam and L. Matthias, Mechanical Optimization of Superconducting Cavities in Continuous Wave, Phys. Rev. Special Top.: Accel. Beams, 2012, 15(2), p 1–10

Y. Xie, Development of Superconducting RF Sample Host Cavities and Study of Pit-induced Cavity Quench, PhD thesis, Cornell University, 2013

M. Rouby and P. Blanchard, Physical and Mechanical Properties of Stainless Steel and Alloys, Stainless Steels, P. Lacombe, B. Baroux and G. Beranger, Ed., Les Editions de Physique Les Ulis, Cedex A, France, 1993, p 139

M. Kuchnir and R. E. Hiller, Welding of Niobium to StainlessSteel, FERMILAB-TM-1831, Fermi National Accelerator Laboratory, Batavia, IL, 1993. http://lss.fnal.gov/archive/test-tm/1000/fermilab-tm-1831.pdf, visited on 04.09.2014

K. Saito, H. Inoue, H. Ao, and N. Satoh, Stainless Steel Flange Bonded to Niobium Tube and Simple Aluminum Sealing, Proc. 10th Workshop on RF Superconductivity, 2001 (Tsukuba), p 531–533

B. Sabirov, J. Budagov, A. Sissakian, G. Shirkov, Yu. Taran, G. Trubnikov, N. Dhanarai, M. Foley, E. Harms, A. Klebaner, D. Mitchell, S. Nagaitsev, W. Soyars, V. Rybakov, Yu. Samarokov, V. Zhigalov, A. Basti, and F. Bedeschi, Recent Advances in Ti and Nb Explosion Welding with Stainless Steel for 2K Operating (ILC Program), Proc. Int. Workshop on Future Linear Colliders, 2011 (Granada), ID 440. http://arxiv.org/ftp/arxiv/papers/1201/1201.3472.pdf visited on 04.09.2014

J. Susta, Development in Fabrication Methods, Proc. SRF Workshop, 1984 (Geneva), p 597–610

J.P. Bacher, E. Chiaveri, and B. Trincat, Brazing of Niobium to Stainless Steel for UHV Applications in Superconducting Cavities, CERN/EF/RF 87-7, CERN, Geneva, Switzerland, 1987. http://cds.cern.ch/record/948207/files/CM-P00058114.pdf

J. D.Fuerst, W.F. Toter, and K.W. Shepard, Niobium to Stainless Steel Braze Transition Development, Proc. 11th Workshop of RF-Superconductivity, 2003, (Lübeck/Travemünder) p 305–307

R. Gentzlinger, K.C.D. Chan, W. B. Haynes, J.P. Kelley, F. Krawczyk, R. Mitchell, D. Montoya, D. Schrage, B. Smith, T. Tajima, J. Kuzminski, B. Rusnak, and H. Safa, Design and Fabrication of SCRF Cavities for the APT Continuous Wave Proton Linac, Proc. 10th Workshop on RF Superconductivity, Sept. 2001 (Tsukuba, Japan), LA-UR-01-5467

S. Rao and Y. Al-Kawaie Ali, Copper Contamination Cracking in Austenitic Stainless Steel Welds, Weld. J., 2010, 89(2), p 46–49

C. Heiple, W. Bennett, and T. Rising, Embrittlement of Several Stainless Steels by Liquid Copper and Liquid Braze Alloys, Mater. Sci. Eng., 1982, 52(3), p 277–289

A. J. Palmer and C. J. Woolstenhulme, Brazing Refractory Metals used in High-temperature Nuclear Instrumentation, Proc. I Int. Conf. on Advancements in Nuclear Instrumentation Measurement Methods and their Applications, June 2009 (Marseille, France), p 1–5

D.W. Liaw and R.K. Shiue, Brazing of Ti-6Al-4V and Niobium Using Three Silver-Base Braze Alloys, Metal. Mater. Trans A, 2005, 36(9), p 2415–2427

R. I. Batista, Brazing of Refractory and Reactive Metals, ASM Handbook: Welding, Brazing and Soldering, vol. 6, D.L. Olson, T.A. Siewert, S. Liu, G.R. Edwards, Ed. (Materials Park, OH), ASM International, 1993, p 947

H.W. Chuang, D.W. Liaw, Y.C. Du, and R.K. Shiue, Brazing of Mo and Nb Using Two Active Braze Alloys, Mater. Sci. Eng. A, 2005, 390(1-2), p 350–361

M.M. Schwartz, Brazing, Metals Park, OH, ASM International, 1987, p 163–164

R.K. Shiue, S.K. Wu, C.H. Chan, and C.S. Huang, Infrared Brazing of Ti-6Al-4V and 17-4 PH Stainless Steel with a Nickel Barrier Layer, Metall. Mater. Trans. A, 2006, 37(7), p 2207–2217

A. Abed, I.S. Jalham, and A. Hendry, Wetting and Reaction Between β′-sialon, Stainless Steel and Cu-Ag Brazing Alloys Containing Ti, J. Eur. Ceram. Soc., 2001, 21(3), p 283–290

T. Yoshida and H. Ohmura, Effect of Nickel Plating on Fe-BCu-Mo and -W, Weld. J., 1982, 61(11), p 363s–372s

R. Asthana and M.Singh, Bonding and Integration of C-C Composite to Cu-CLAD-Molybdenum for Thermal Management Applications, Advanced Processing and Manufacturing Technologies for Structural and Multifunctional Materials II, Ceramic Engineering and Science Proceedings, 29(9), T. Ohji and M. Singh, Ed., Wiley, 2008, p 15–26

B. Bonin and R. W. Roth, Q Degradation of Niobium Cavities due to Hydrogen Contamination, Proc. 5th Workshop on RF Superconductivity SRF 1991, 1991 (Hamburg), p 210–244

R. Singh, K. Yedle, and A.K. Jain, Development of Vacuum Brazing Furnace, IVSNS-2005, 2005 (Gandhinagar, India)

Vacuum Technology: Flange Dimensions, International Organization for Standardization”, ISO1609:1986, International Organization for Standardization, Geneva, Switzerland, 1986

Vacuum Technology: Dimensions of Clamped-Type Quick Release Couplings, ISO 2861:2013, International Organization for Standardization, Geneva, Switzerland, 2013

R. Poggiani, Materials and Components of Possible Interest for Cryogenic Operation of Einstein Telescope, ET-026-09, Issue 1, University of Pisa and INFN Pisa, 2009

E.D. Marquardt, J.P. Le, and R. Radebaugh, Cryogenic Material Properties Database, Proc. 11th Int. Cryocooler Conf., June 2000 (Keystone, SD)

Low Temperature Properties of Materials, USPAS Cryogenics Short Course, June 14-18, 2010 (Boston, MA). http://uspas.fnal.gov/materials/10MIT/Lecture_1.2.pdf

S. Mondal, L.C. Pathak, K. Venkateswarlu, S.K. Das, and A.K. Ray, Development and Characterization of Ag-Cu-TiAlloys for Ceramic Brazing, Proc. Indo-Malaysian Workshop on Advanced Materials (WAM-2002), L.C. Pathak, K. Venkateswarlu, A. Bandopadhyay, and A.K. Ray, Ed., 2002 (Jamshedpur, India), Allied Publishers Pvt. Ltd., New Delhi, 2003, p 121–128

D.P. Yadav, R. Kaul, P. Ganesh, R. Shiroman, R. Sridhar, and L.M. Kukreja, Study on Vacuum Brazing of High Purity Alumina for Application in Proton Synchrotron, Mater. Des., 2014, 64, p 415–422

B. Skoczen, “Stability, Fatigue and Optimization of Thin-walled Structures under Cryogenic Conditions”, CERN-2001-001, CERN, Geneva, Switzerland, 2001. http://dx.doi.org/10.5170/CERN-2001-001

Specification for Furnace Brazing, AWS C3.6M/C3.6-2008, American Welding Society, Orlando, FL, 2008

A. Basti, F. Bedeschi, J. Budagov, F. Frasconi, S. Linari, B. Sabirov, A. Sissakian, and A. Sukhanova, Leak Rate Measurements on Bimetallic Transition Samples for ILC Cryomodules, Public Note/ACCDT/CRYOMOD-ILC-NOTE-2007-032, Sept. 3, 2007, INFN, Italy and JINR, Russia. http://ilcdoc.linearcollider.org/record/11429/files/?ln=ru

R.L. O’Brien, Ed., Welding Handbook, Welding Processes, vol. 2, 8th edn., 1991 (Miami, FL), American Welding Society, p 401–404

Acknowledgments

Authors are thankful to Dr. P. D. Gupta, Director, Raja Ramanna Centre for Advanced Technology for his constant support and guidance during the course of the study. The authors wish to thank Mrs. Pragya Tiwari for her help in SEM-EDS analysis of vacuum brazed specimens and Mr. Avinash Puntambekar for providing niobium pipes for the experiments. The authors thankfully acknowledge UGC-DAE-CSR for providing SEM-EDS facility for characterization of the specimens. They express their sincere thanks to Mr. V. K. Ahire of UGC-DAE-CSR for EDS analysis of our specimens. The authors thank Mr. A. P. Singh, Mr. C. Manikandan and Mr. G. S. Deshmukh for their useful contribution in chemical cleaning and nickel electroplating. They thankfully acknowledge technical assistance of Mr. R. Chouhan, Mr. S. K. Chourasia, Mr. J. S. Pulickal, Mr. V. Pal, Mr. Om Praksh, Mr. A. Chowdhury, Mr. U. Chatterji, Mr. N. More, Mr. T. R. Meena, Mr. D. C. Nagpure and Mr. Ram Nihal Ram during various stages of the investigation. The authors wish to thank Mr. J. D. Zolpara and Mr. B. Oraon for preparing drawings of test specimens and fixtures.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, A., Ganesh, P., Kaul, R. et al. A New Vacuum Brazing Route for Niobium-316L Stainless Steel Transition Joints for Superconducting RF Cavities. J. of Materi Eng and Perform 24, 952–963 (2015). https://doi.org/10.1007/s11665-014-1312-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1312-1