Abstract

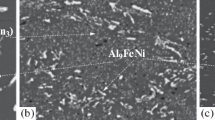

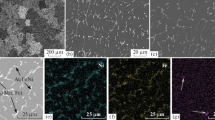

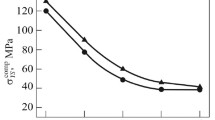

The paper deals with a peculiar rheological behavior of the Al-Mg-Sc-Zr alloy at deformation temperatures of 330 and 360 °C and a strain rate of 0.05 s−1. It has been found that the strain resistance curve for this material consists of several portions. First there is material hardening, then softening, and again hardening. The application of the electron backscatter diffraction technique and transmission electron microscopy has elucidated that in-situ recrystallization is the main process of softening at the temperatures studied. The appearance of the second portion of hardening on the strain resistance curve results from inhibited in-situ recrystallization. At the deformation temperature of 330 °C, as distinct from the temperature of 360 °C, a small number of grains are formed on the boundaries of original grains because of insufficiently active dynamic polygonization. The presence of abounding intermetallics in the microstructure causes the development of the barrier effect of blocking free dislocations, grain and subgrain boundaries by intermetallics, thus enhancing material hardening.

Similar content being viewed by others

References

V.G. Davydov, T.D. Rostova, V.V. Zakharov, Y.A. Filatov, and V.I. Yelagin, Scientific Principles of Making an Alloying Addition of Scandium to Aluminium Alloys, Mater. Sci. Eng. A, 2000, 280(1), p 30–36

V. Singh, K.S. Prasad, and A.A. Gokhale, Microstructure and Age Hardening Response of Cast Al-Mg-Sc-Zr Alloys, J. Mater. Sci., 2004, 39(8), p 2861–2864

A.V. Konovalov and A.S. Smirnov, Viscoplastic Model for the Strain Resistance of 08Kh18N10T Steel at a Hot-Deformation Temperature, Russ. Metall., 2008, 2, p 138–141

Y.C. Lin and X.-M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32(4), p 1733–1759

A. Momeni, G.R. Ebrahimi, M. Jahazi, and P. Bocher, Microstructure Evolution at the Onset of Discontinuous Dynamic Recrystallization: A Physics-Based Model of Subgrain Critical Size, J. Alloys Compd., 2014, 587, p 199–210

A.R. Eivani, J. Zhou, and J. Duszczyk, Numerical Modeling of Subgrain Growth of Hot Extruded Al-4.5Zn-1Mg Alloy in the Presence of Nanosized Dispersoids, Comput. Mater. Sci., 2014, 86, p 9–16

I. Schindler, P. Kawulok, E. Hadasik, and D. Kuc, Activation Energy in Hot Forming and Recrystallization Models for Magnesium Alloy AZ31, J. Mater. Eng. Perform., 2013, 22(3), p 890–897

K. Ihara and Y. Miura, Dynamic Recrystallization in Al-Mg-Sc Alloys, Mater. Sci. Eng. A, 2004, 387-389, p 647–650

R. Kaibyshev, E. Avtokratova, A. Apollonov, and R. Davies, High Strain Rate Superplasticity in an Al-Mg-Sc-Zr Alloy Subjected to Simple Thermomechanical Processing, Scr. Mater., 2006, 54(12), p 2119–2124

H. Akamatsu, T. Fujinami, Z. Horita, and T.G. Langdon, Influence of Rolling on the Superplastic Behavior of an Al-Mg-Sc Alloy After ECAP, Scr. Mater., 2001, 44(5), p 759–764

O. Sitdikov, T. Sakai, E. Avtokratova, R. Kaibyshev, Y. Kimura, and K. Tsuzaki, Grain Refinement in a Commercial Al-Mg-Sc Alloy Under Hot ECAP Conditions, Mater. Sci. Eng. A, 2007, 444(1-2), p 18–30

O. Sitdikov, T. Sakai, E. Avtokratova, R. Kaibyshev, K. Tsuzaki, and Y. Watanabe, Microstructure Behavior of Al-Mg-Sc Alloy Processed by ECAP at Elevated Temperature, Acta Mater., 2008, 56(4), p 821–834

D. Zhemchuzhnikova, A. Mogucheva, and R. Kaibyshev, Mechanical Properties and Fracture Behavior of an Al-Mg-Sc-Zr Alloy at Ambient and Subzero Temperatures, Mater. Sci. Eng. A, 2013, 565, p 132–141

E. Avtokratova, O. Sitdikov, M. Markushev, and R. Mulyukov, Extraordinary High-Strain Rate Superplasticity of Severely Deformed Al-Mg-Sc-Zr Alloy, Mater. Sci. Eng. A, 2012, 538, p 386–390

F. Musin, R. Kaibyshev, Y. Motohashi, and G. Itoh, High Strain Rate Superplasticity in a Commercial Al-Mg-Sc Alloy, Scr. Mater., 2004, 50(4), p 511–516

K. Verbeken, N. Van Caenegem, and D. Raabe, Identification of Epsilon Martensite in a Fe-Based Shape Memory Alloy by Means of EBSD, Micron, 2009, 40(1), p 151–156

S. Dziaszyk, E.J. Payton, F. Friedel, V. Marx, and G. Eggeler, On the Characterization of Recrystallized Fraction Using Electron Backscatter Diffraction: A Direct Comparison to Local Hardness in an IF Steel Using Nanoindentation, Mater. Sci. Eng. A, 2010, 527(29-30), p 7854–7864

Acknowledgments

The work was partially financially supported by the grant of RFBR (project No 14-08-31262) and the Program of UB RAS (project No 12-T-1-1010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Smirnov, A.S., Konovalov, A.V., Pushin, V.G. et al. Peculiarities of the Rheological Behavior for the Al-Mg-Sc-Zr Alloy Under High-Temperature Deformation. J. of Materi Eng and Perform 23, 4271–4277 (2014). https://doi.org/10.1007/s11665-014-1211-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1211-5