Abstract

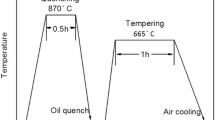

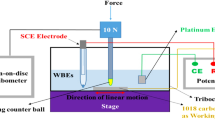

During drilling process, if oil and gas overflow containing H2S enters drilling fluids, the performance of drill pipes will decline significantly within a short time. In this paper, S135 drill pipe specimen was immersed in the saturated solution of H2S at room temperature for 6, 12, 18, and 24 h, respectively. The tensile properties and impact properties of S135 drill pipe were determined before and after immersion for comparison. In addition, the S135 specimens were immersed for 3 days at 80 °C to determine the changes in fatigue performance. The test results indicated that the yield strength of S135 material fluctuated with immersion time increasing and the tensile strength slightly varied with immersion time. But the plasticity index of S135 decreased significantly with the increase in immersion time. The impact energy of S135 steel also fluctuated with the increase in immersion time. After 3-day immersion at 80 °C, the fatigue properties of S135 steel decreased, and fatigue life showed the one order of magnitude difference under the same stress conditions. Moreover, fatigue strength was also decreased by about 10%. The study can guide security management of S135 drill pipe under the working conditions with oil and gas overflow containing H2S, reduce drilling tool failures, and provide technical support for drilling safety.

Similar content being viewed by others

References

G.Y. Zhu, J.X. Dai, S.C. Zhang et al., Generation Mechanism and Distribution Characteristics of Hydrogen Sulfide Bearing Gas in China, Natural Gas Geosci., 2004, 15(2), p 166–170 ([in Chinese])

W.H. Liu, B. Gao, Z.N. Zhang et al., H2S Formation and Enrichment Mechanisms in Medium to Large Scale Natural Gas Fields (Reservoirs) in the Sichuan Basin, Pet. Explor. Dev., 2010, 37(5), p 513–522

B.K. Gao, X.Z. Han, and H.Q. Zhang, Study on H2S Monitoring Technique for High Risk Wellsite, Procedia Eng., 2012, 45, p 898–903

R.A. Oriani, Whitney Award Lecture-1987: Hydrogen-The Versatile Embrittler, Corrosion, 1987, 43(7), p 390–397

A.R. Troiano, The Role of Hydrogen and Other Interstitials in the Mechanical Behavior of Metals, Trans. ASM, 1960, 52(1), p 54–80

G.T. Park, S.U. Koh, H.G. Jung et al., Effect of Microstructure on the Hydrogen Trapping Efficiency and Hydrogen Induced Cracking of Linepipe Steel, Corros. Sci., 2008, 50(7), p 1865–1871

S.N. Smith and M.W. Joosten, Corrosion of Carbon Steel by H2S in CO2 Containing Oilfield Environments, Corrosion, 2006, 2006, p 1–26

J. Capelle, J. Gilgert, I. Dmytrakh et al., Sensitivity of Pipelines with Steel API, X52 to Hydrogen Embrittlement, Int. J. Hydrogen Energy, 2008, 33(24), p 7630–7641

API Spec 5D, Specification for Drill Pipe, 5th edn, Washington DC, 2001

Y.G. Liu, F.P. Li, X. Xu et al., Simulation Technology in Failure Analysis of Drill Pipe, Procedia Eng., 2011, 12, p 236–241

Y.H. Lin, X. Qi, D.J. Zhu et al., Failure Analysis and Appropriate Design of Drill Pipe Upset Transition Area, Eng. Fail. Anal., 2013, 31, p 255–267

F.P. Li, L.H. Han, Y.G. Liu et al., Investigation on Toughness Index of High Grade Steel Drill Pipe, J. China Univ. Pet., 2011, 35(5), p 130–134 ([in Chinese])

L. Bertini and P. Conti, Fatigue Crack Growth Behavior of Four Structural Steels in Air and in a Geothermal Fluid Environment, Int. J. Fatigue, 1992, 14(2), p 75–83

ISO 11961, Petroleum and Natural Gas Industries - Steel Drill Pipe, 2nd ed, Geneva, 2008

NACE TM0177, Laboratory Testing of Metals for Resistance to Specific Forms of Environmental Cracking in H 2 S Environments, 5th ed, Houston, 2005

O.H. Basquin, The Exponential Law of Endurance Tests, Proc. Am. Soc. Test. Mater., 1910, 10, p 625–630

Y.X. Zhao, B. Yang, M.F. Feng et al., Probabilistic Fatigue S-N Curves Including the Super-Long Life Regime of a Railway Axle Steel, Int. J. Fatigue, 2009, 31(10), p 1550–1558

Y.X. Zhao and B. Yang, Probabilistic Measurements of the Fatigue Limits Data from a Small Sampling Up-and-Down Test Method, Int. J. Fatigue, 2008, 30(12), p 2094–2103

H.J. Schindler, Estimation of the Dynamic J-R-curve from A Single Impact Bending Test, Mechanisms and Mechanics of Damage and Failure, ECF 11th, 1996, p 2007-2012

Y.M. Qi, H.Y. Luo, S.Q. Zheng et al., Effect of Immersion Time on the Hydrogen Content and Tensile Properties of A350LF2 Steel Exposed to Hydrogen Sulphide Environments, Corros. Sci., 2013, 69, p 164–174

M.A. Lucio-Garcia, J.G. Gonzalez-Rodriguez, and M. Casales, Effect of Heat Treatment on H2S Corrosion of a Micro-Alloyed C-Mn Steel, Corros. Sci., 2009, 51, p 2380–2386

W.Y. Chu, Hydrogen Damage and Delay Fracture, Metallurgical Industry Press, Beijing, 1988 ([in Chinese])

R. Wang, Effects of Hydrogen on the Fracture Toughness of a X70 Pipeline Steel, Corros. Sci., 2009, 51, p 2803–2810

H.J. Maier, W. Popp, and H. Kaesche, Effects of Hydrogen on Ductile Fracture of a Spheroidized Low Alloy Steel, Mater. Sci. Eng. A, 1995, 191(1), p 17–26

S.X. Mao and M. Li, Mechanics and Thermodynamics on the Stress and Hydrogen Interaction in Crack Tip Stress Corrosion: Experiment and Theory, J. Mech. Phys. Solids, 1998, 46(6), p 1125–1137

R.A. Oriani and E.H. Josephic, Equilibrium Aspects of Hydrogen Induced Cracking of Steels, Acta Metall., 1974, 22, p 1065–1074

A.R. Troiano, The Role of Hydrogen and Other Interstitials in the Mechanical Behaviour of Metals, Trans. ASM, 1960, 52, p 54–80

X.Q. Wu and I.S. Kim, Effect of Strain Rate and Temperature on Tensile Behavior of Hydrogen-Charged SA508 C1. 3 Pressure Vessel Steel, Mater. Sci. Eng. A, 2003, 348, p 309–318

X.G. Jiang, W.Y. Chu, and J.M. Xiao, Nucleation Mechanism of Hydrogen-Facilitating Cavity, China Sci. (Series A), 1994, 24(6), p 668–672 ([in Chinese])

U. Hadam and T. Zakroczymski, Absorption of Hydrogen in Tensile Strained Iron and High-Carbon Steel Studied by Electrochemical Permeation and Desorption Techniques, Int. J. Hydrog. Energy, 2009, 34, p 2449–2459

G.P. Tiwari, A. Bose, J.K. Chakravartty et al., A Study of Internal Hydrogen Embrittlement of Steels, Mater. Sci. Eng. A, 2000, 286(2), p 269–281

Y. Murakami and M. Endo, Effects of Defects, Inclusions and Inhomogeneities on Fatigue Strength, Int. J. Fatigue, 1994, 16(3), p 163–182

K. Shiozawa and Y. Morii, Subsurface Crack Initiation and Propagation Mechanism in High-Strength Steel in a Very High Cycle Fatigue Regime, Int. J. Fatigue, 2006, 28, p 1521–1532

E.V. Chatzidouros, V.J. Papazoglou, T.E. Tsiourva, and D.I. Pantelis, Hydrogen Effect on Fracture Toughness of Pipeline Steel Welds, with in Situ Hydrogen Charging, Int. J. Hydrog. Energy, 2001, 36(19), p 12626–12643

Acknowledgment

This work is supported by The National Natural Science Foundation of China entitled” The synergistic effect of corrosion and pulsating impact loads on the fatigue damage and control of ultra-high strength drilling string”. No. 51374177.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dezhi, Z., Gang, T., Junying, H. et al. Effect of Immersion Time on the Mechanical Properties of S135 Drill Pipe Immersed in H2S Solution. J. of Materi Eng and Perform 23, 4072–4081 (2014). https://doi.org/10.1007/s11665-014-1198-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1198-y