Abstract

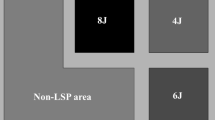

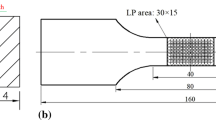

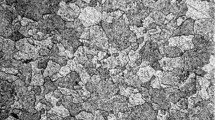

The surface of 40CrNiMo steel was quenched with a CO2 laser, Charpy impact test was conducted at temperatures of 20, 0, and −20 °C, and the impact absorption energies were measured. The fracture morphologies were observed with SEM, and the influence of microhardness, residual stress, and retained austenite on mechanical behavior of impact fracture after laser quenching was discussed. The results show that the hardened layer depth is more than 1 mm after laser quenching, and hardness is about 480-500 HV. The fracture morphology of the sample is dimple rupture at a temperature of 20 °C; with the lower temperature the fracture dimples become smaller. At a temperature of −20 °C, the fracture morphologies change from ductile to brittle, which is mainly cleavage fracture. The increase in surface hardness, production of compressive residual stress, and existence of retained austenite after laser quenching are the main mechanisms of increasing impact toughness.

Similar content being viewed by others

References

R.L. McDaniels, S.A. White, K. Liaw et al., Effects of a Laser Surface Processing Induced Heat-Affected Zone on the Fatigue Behavior of AISI, 4340 Steel, Mater. Sci. Eng., 2008, 485, p 500–507

Z. Sisi, C. Shanhai, Z. Tingting et al., Strengthening and Application Research of Carbo-niobiumizing of 40CrNiMo Steel, Heat Treat. Met., 2012, 37(3), p 99–102

Li Jie, Wang Li, Li Zhi et al., Effect of Heat Treatment on Impact Fracture Surface of High Co-Ni Ultralight Strength Steel, J. Aeronaut. Mater., 2008, 28(1), p 35–39

L. Jinguo, Y. Shuzheng, J. Gong et al., Study on the Microstructure and Property of CrMnMo Anti-wear Steel in the State of Quenching and Tempering, J. China Coal Soc., 2003, 28(5), p 552–556

L. Gang, X. Jun, K. Jun et al., Microstructure and Properties of GCr15 Steel Treated by Laser Quenching, Trans. Mater. Heat Treat., 2010, 31(4), p 129–133

C. Zhaoyun, Z. Guijuan, and Z. Chen, Microstructure and Hardness Investigation of 17-4PH Stainless Steel by Laser Quenching, Mater. Sci. Eng. A, 2012, 532(1), p 536–541

G. Qingfeng, Z. Hong, W. Hongyan et al., Laser Surface Hardening and Fatigue Resistance Ability Analysis of 40CrNiMoA Gear, Appl. Laser, 2002, 22(5), p 469–473

A.H. Meysami, R. Ghasemzadeh, S.H. Seyedein et al., Physical Simulation of Hot Deformation and Microstructural Evolution for 42CrMo4 Steel Prior to Direct Quenching, J. Iron Steel Res., 2009, 16(6), p 47–51

C. Yiyuan, W. Yong, S. Yijian et al., Investigation on Nitrogen Distribution and Corrosion Resistance of 35CrMoA Steel in Laser Quenching-Nitriding, Trans. China Weld. Inst., 2011, 32(1), p 69–72

Y.H. Liu, Z.X. Guo, Y. Yang et al., Laser (a pulsed Nd:YAG) Cladding of AZ91D Magnesium Alloy with Al and Al2O3 Powders, Appl. Surf. Sci., 2006, 253(4), p 1722–1728

K. Lu, Nanocrystalline Metals Crystallized from Amorphous Solids: Nanocrystallization, Structure, and Properties, Mater. Sci. Eng. R, 1996, 16, p 161–221

Q. Yuebo, H. Xinquan, C. Bin et al., Effect of Residual Austenite Content on Impact Toughness of the Filler Metal of 2.25Cr-1Mo Steel, J. Mech. Eng., 2011, 47(14), p 44–48

S. Chatterjee and H.K.D.H. Bhadeshia, TRIP-Assisted Steels: Cracking of High Carbon Martensite, Mater. Sci. Technol., 2006, 22, p 645–649

C.G. Lee, S.-J. Kim, T.-H. Lee et al., Effects of Volume Fraction and Stability of Retained Austenite on Formability in a 0.1C-1.5Si-1.5Mn-0.5Cu TRIP-Aided Cold-Rolled Steel Sheet, Mater. Sci. Eng. A, 2004, 371, p 16–23

Z. Ke, Z. Meihan, G. Zhenghong et al., A New Effect of Retained Austenite on Ductility Enhancement in High-Strength Quenching-Partitioning-Tempering Martensitic Steel, Mater. Sci. Eng. A, 2011, 29(30), p 8486–8491

Acknowledgments

Financial support of this research by Jiangsu Province Science and Technology Support Program (Industry) (BE2012066) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dejun, K., Lei, Z. Effects of Laser Quenching on Impact Toughness and Fracture Morphologies of 40CrNiMo High Strength Steel. J. of Materi Eng and Perform 23, 3695–3702 (2014). https://doi.org/10.1007/s11665-014-1164-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1164-8