Abstract

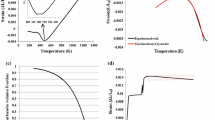

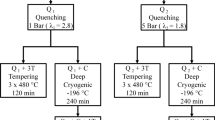

The microstructure of a cold-worked tool steel (AISI D2) with various thermo-mechanical treatments was examined in the current study to identify the effects of these treatments on phases. X-ray diffraction was used to identify phases. Microstructural changes such as spheroidization and coarsening of carbides were studied. Thermodynamic calculations were used to verify the results of the differential thermal analysis. It was found that soaking temperature and time have a large influence on dissolution, precipitation, spheroidization, and coalescence of carbides present in the steel. This consequently influences the hot workability and final properties.

Similar content being viewed by others

References

G. Roberts, G. Krauss, and R. Kennedy, Tool Steels, 5th ed., ASM International, Materials Park, 1998

C.A.C. Imbert and H.J. McQueen, Hot Ductility of Tool Steels, Can. Metall. Q., 2001, 40, p 235–244

T.K. Kim, J.H. Baek, C.H. Han, S.H. Kim, and C.B. Lee, Effects of the Fabrication Process Parameters on the Precipitates and Mechanical Properties of a 9Cr-2W-V-Nb Steel, J. Nucl. Mater., 2009, 389, p 359–364

C.A.C. Imbert and H.J. McQueen, Dynamic Recrystallisation of D2 and W1 Tool Steel, Mater. Sci. Technol., 2000, 16, p 532–538

L. Bourithis, G.D. Papadimitriou, and J. Sideris, Comparison of Wear Properties of Tool Steels AISI, D2 and O1 with the Same Hardness, Tribol. Int., 2006, 39, p 479–489

M.R. Ghomashchi and C.M. Sellars, Microstructural Changes in As-Cast M2 Grade High Speed Steel During Hot Forging, Metall. Mater. Trans. A, 1993, 24A, p 2171–2180

T. Vecko Pirtovsek, G. Kugler, P. Fajfar, M. Fazarinc, I. Perus, and M. Tercelj, Hot Forming of AISI, D2 Tool Steel, RMZ-Mater. Geoenviron., 2007, 54, p 1–14

I.C. Eenst and D. Duh, Properties of Cold-Work Tool Steel X155CrVMo12-1 Produced via Spray Forming and Conventional Ingot Casting, J. Mater. Sci., 2004, 39, p 6835–6838

T. Vecko Pirtovsek, G. Kugler, M. Godec, and M. Tercelj, Microstructural Characterization During the Hot Deformation of 1.17C-11.3Cr-1.48V-2.24W-1.35Mo Ledeburitic Tool Steel, Mater. Charact., 2011, 63, p 189–197

T. Vecko Pirtovsek and P. Fajfar, Processing the PK324 Duplex Stainless Steel: Influences on Hot Deformability of the As-Cast Microstructure, RMZ-Mater. Geoenviron., 2009, 56, p 126–136

ASM Handbook Volume 9: Metallography and Microstructures, ASM International, Materials Park, OH, 2004, p 644–669

S. Wilmes and G. Kientopf, Carbide Dissolution Rate and Carbide Contents, Usual High Alloyed Tool Steels at Austenitizing Temperatures between 900 °C and 1250 °C, Proceedings of the 6th International Conference on Tooling, J. Bergström, G. Fredriksson, M. Johansson, O. Kotik, and F. Thuvander, Ed., Karlstad, Sweden, 2002, p 533–547

D.I. Uhlenhaut, J. Kradolfer, W. Püttgen, J.F. Löffler, and P.J. Uggowitzer, Structure and Properties of a Hypoeutectic Chromium Steel Processed in the Semi-Solid State, Acta Mater., 2006, 54, p 2727–2734

T. Nykiel and T. Hryniewicz, Quantitative Approach to Coagulation Coalescence and Polygonization of Carbides in D3 Tool Steel, Metall. Mater. Trans. A, 2000, 31A, p 2661–2665

Acknowledgments

The authors would like to thank Prof. H. K. D. H. Bhadeshia for stimulating discussions regarding the research described in article. Furthermore, the authors wish to thank Mr. M. Kadis for providing the forged samples, and Ms. T. Vecko-Pirtovsek and Mr. M. Zdovc for their technical assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bombac, D., Fazarinc, M., Podder, A.S. et al. Study of Carbide Evolution During Thermo-Mechanical Processing of AISI D2 Tool Steel. J. of Materi Eng and Perform 22, 742–747 (2013). https://doi.org/10.1007/s11665-012-0340-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0340-y