Abstract

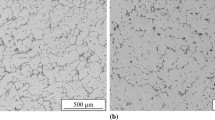

This study investigates the mechanical properties of Al-7Si-0.3Mg (A356) alloy affected by the spinning deformation processing (SDP). The cast structure of the A356 alloy becomes elongated with increasing reduction in thickness. This leads to reduction of casting defects, and refines and distributes the eutectic silicon phase throughout the Al-matrix. The hardness tends to reach a steady value due to the uniformity of the microstructure with the reduction in thickness. The SDP leads to a re-arrangement in the eutectic region, which forces the propagation of cracks through the ductile α-Al phase. The tensile strength and elongation increases accordingly. The improvement on tensile strength and elongation produces the best quality index for A356 alloy.

Similar content being viewed by others

References

D. Carney, Wheel Design and Engineering, Autom. Eng. Int., 2001, 109, p 54–59

M. Merlin, G. Timelli, F. Bonollo, and G.L. Garagnani, Impact Behaviour of A356 Alloy for Low-pressure Die Casting Automotive Wheels, J. Mater. Process. Technol., 2009, 209, p 1060–1073

C.C. Wong, T.A. Dean, and J. Lin, A Review of Spinning, Shear Forming and Flow Forming Processes, Int. J. Mach. Tools Manuf., 2003, 43, p 1419–1435

D. Polit, Metal Spinning in the Automotive Industry, Sheet Met. Ind., 1995, 72, p 31–32

Y.C. Cheng, C.K. Lin, A.H. Tan, J.C. Lin, and S.L. Lee, Effect of Spinning Deformation Processing on the Wear and Corrosion Properties of Al-7Si-0.3Mg Alloys, Mater. Manuf. Process., 2010, 25, p 689–695

O. Music, J.M. Allwood, and K. Kawai, A Review of the Mechanics of Metal Spinning, J. Mater. Process. Technol., 2010, 210, p 3–23

A.M.A. Mohamed, A.M. Samuel, F.H. Samuel, and H.W. Doty, Influence of Additives on the Microstructure and Tensile Properties of Near-Eutectic Al-10.8%Si Cast Alloy, Mater. Des., 2009, 30, p 3943–3957

Y.C. Tsai, C.Y. Chou, S.L. Lee, C.K. Lin, J.C. Lin, and S.W. Lim, Effect of Trace La Addition on the Microstructures and Mechanical Properties of A356 (Al–7Si–0.35Mg) Aluminum Alloys, J. Alloys Compd., 2009, 487, p 157–162

Z. Ma, E. Samuel, A.M.A. Mohamed, A.M. Samuel, F.H. Samuel, and H.W. Doty, Influence of Aging Treatments and Alloying Additives on the Hardness of Al-11Si-2.5Cu-Mg Alloys, Mater. Des., 2010, 31, p 3791–3803

C.Y. Chou, K.W. Wang, S.L. Lee, and T.S. Yang, Modifying Al–7Si–0.35Mg Alloys Using Equal Channel Angular Extrusion, Mater. Lett., 2008, 62, p 2469–2472

M.J. Roy, R.J. Klassen, and J.T. Wood, Evolution of Plastic Strain During a Flow Forming Process, J. Mater. Process. Technol., 2009, 209, p 1018–1025

D.L. Zhang and L. Zheng, The Quench Sensitivity of Cast Al-7 Wt Pct Si-0.4 Wt Pct Mg Alloy, Metall. Mater. Trans. A, 1996, 27A, p 3983–3991

C.Y. Yang, S.L. Lee, C.K. Lee, and J.C. Lin, Effect of Sr and Sb Modifiers on the Sliding Wear of A357 Alloy Under Varying Pressure and Speed Conditions, Wear, 2006, 261, p 1348–1358

F.T. Lee, J.F. Major, and F.H. Samuel, Effect of Silicon Particles on the Fatigue Crack Growth Characteristics of Al-12 wt pct Si-0.35 wt pct Mg-(0 to 0.02) wt pct Sr Casting Alloys, Metall. Mater. Trans. A, 1995, 26, p 1553–1570

M.L. Santella, T. Engstron, D. Storjohann, and T.Y. Pan, Effect of Friction Stir Processing on Mechanical Properties of the Cast Aluminum Alloys A319 and A356, Scripta Mater., 2005, 53, p 201–206

M. Drouzy, S. Jacob, and M. Richard, Le Diagramme Charge de Rupture des Alliages d’aluminium, Foundries, 1976, 355, p 139–147

Acknowledgments

The authors would like to thank the National Science Council of the Republic of China, Taiwan for financially supporting this research under Contract No. NSC99-2622-E-008-007-CC3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, YC., Lin, CK., Tan, AH. et al. Effect of the Spinning Deformation Processing on Mechanical Properties of Al-7Si-0.3Mg Alloys. J. of Materi Eng and Perform 21, 1873–1878 (2012). https://doi.org/10.1007/s11665-011-0089-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-011-0089-8