Abstract

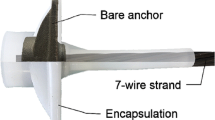

The purpose of this study was to determine the acceptability of nonpenetrating, key-locked inserts in 2099 aluminum-lithium. The tests conducted to make this assessment were: (1) microscopic examination for thread damage and delaminations after key installation, (2) pull-out load at 21 °C (70 °F) and −179 °C (−290 °F), and (3) mechanical cycling tests at room temperature and −179 °C (−290 °F). The test results indicated that for the three sizes evaluated, key-locked inserts in 2099-T6 and 2099-T8 were acceptable and although delaminations did occur on some T6 temper specimens, it was only as a failure mode at ultimate load and such behavior was judged to be acceptable.

Similar content being viewed by others

References

R. Dunton, Threaded Inserts for Solving Assembly Problems, Assembly Eng. 23(4) 1980, 30–36

D.P. Viscio, How Inserts Help Lightweight Structures, Mach. Des. 47(14) 1975, 113–116

K.T.V. Rao, R. Ritchie, Mechanisms Influencing the Cryogenic Fracture-Toughness Behavior of Al-Li Alloys, Acta Metall. Mater. 38(11) 2309–2326, 1990

S.G. Keener, “Mechanical Joining Characteristics of Al-Li (2090) in a Production Environment”, SAE Technical Paper 912640, Aerofast 91, Nashville, Tennessee, Nov. 5–6, 1991

D. Roubinet, D.M. Shoe, and G. Moon, “Aluminum Lithium (Alloy 2090) Fastening Evaluation for the 777”, SAE Paper 941844 in the Proceeding of the Aerofast Symposium, Presented October 1994

M. Tarkanian, unpublished Boeing investigation on Drilling and Coining of 2099, May 2002

Military Handbook: Metallic Materials and Elements for Aerospace vehicle Structures. December 1998

NAS1394, National Aerospace Standard 21 August 1995 “Insert-Threaded Metal, Lightweight, Self-Locking, and Non Self-Locking”

NAS1395, National Aerospace Standard 21 August 1995 “Insert-Threaded Metal, Heavy Duty, Self-Locking, and Non Self-Locking”

Acknowledgments

The authors gratefully acknowledge the National Science Foundation and Their Research Experiences for Undergraduates program (Grant No. EEC-0353668). Ms. Esther Bolding is the program manager.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Babel, H., Gibson, J., Tarkanian, M. et al. 2099 Aluminum-Lithium with Key-Locked Inserts for Aerospace Applications. J. of Materi Eng and Perform 16, 584–591 (2007). https://doi.org/10.1007/s11665-007-9096-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-007-9096-1