Abstract

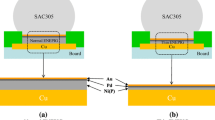

Low-temperature soldering constitutes a promising solution in interconnect technology with the increasing trend of heat-sensitive materials in integrated circuit packaging. Experimental work was carried out to investigate the effect of electroless Ni/electroless Pd/immersion gold (ENEPIG) layer thicknesses on Sn-Bi-Ag solder joint integrity during extended reflow at peak temperatures as low as 175°C. Optimizations are proposed to obtain reliable solder joints through analysis of interfacial microstructure with the resulting joint integrity under extended reflow time. A thin Ni(P) layer with thin Pd led to diffusion of Cu onto the interface resulting in Ni3Sn4 intermetallic compound (IMC) spalling with the formation of thin interfacial (Ni,Cu)3Sn4 IMCs which enhance the robustness of the solder after extended reflow, while thick Ni(P) with thin Pd resulted in weakened solder joints with reflow time due to thick interfacial Ni3Sn4 IMCs with the entrapped brittle Bi-phase. With a suitable thin Ni(P), the Pd thickness has to be optimized to prevent excessive Ni–P consumption and early Cu outward diffusion to enhance the solder joint during extended reflow. Based on these findings, suitable Ni(P) and Pd thicknesses of ENEPIG are recommended for the formation of robust low-temperature solder joints.

Similar content being viewed by others

References

J. Mizsei and J. Lappalainen, in 30th Eurosensors Conference (2016), pp. 1070–1073

F. Song and B.E. White Jr., arXiv:1608.03911 [cond-mat.mtrl-sci] (2016)

M.O. Thompson, C. Lew, J.Carlson, and P. Brahms, in 17th IEEE International Symposium on the Applications of Ferroelectrics (2008)

M.T. Ghoneim and M.M. Hussain, Electronics 4, 424 (2015). https://doi.org/10.3390/electronics4030424.

J. Wang, H.S. Liu, L.B. Liu, and Z.P. Jin, J. Electron. Mater. 35, 1842 (2006).

C. Wu, J. Shen, and C. Peng, J. Mater. Sci. Mater. Electron. 23, 14 (2012). https://doi.org/10.1007/s10854-011-0383-0.

K. Suganuma, T. Sakai, K.S. Kim, Y. Takagi, J. Sugimoto, and M. Ueshima, IEEE Trans. Electron. Packag. Manuf. 25, 257 (2002).

D.M. Zhang, G.F. Ding, H. Wang, Z. Jiang, and J.Y. Yao, J. Funct Mater Dev. 12, 211 (2006).

F. Christopher, S. Timo, and K. Michael, J. Mater. Sci. 47, 4036 (2012).

J.H. Lau, in Reliability of RoHS-Compliant 2D and 3D IC Interconnects. Reliability of Low-Temperature Lead-Free (SnBiAg) Solder Joints, Chapter (McGraw-Hill Professional, 2011), AccessEngineering

Q.K. Zhang and Z.F. Zhang, Mater. Sci. Eng. A 528, 2686 (2011).

M.C. Liao, P.S. Huang, Y.H. Lin, C.Y. Huang, M.Y. Tsai, and T.C. Huang, in International Microsystems, Packaging, Assembly and Circuits Technology Conference (2014), pp. 397–400. https://doi.org/10.1109/impact.2014.7048436.

M. Mccormack, H.S. Chen, G.W. Kammlott, et al., Journal of Electron. Mater. 26, 954 (1997). https://doi.org/10.1007/s11664-997-0281-7.

S. Sakuyama, T. Akamatsu, K. Uenishi, and T. Sato, Trans. Jpn. Inst. Electron. Packag. 2, 98 (2009).

S.M. Lee, J.W. Yoon, and S.B. Jung, J. Mater. Sci. Mater. Electron. 26, 1649 (2015). https://doi.org/10.1007/s10854-014-2589-4.

M. Ratzker, A. Pearl, M. Osterman, M. Pecht, and G. Milad, J. Electron. Mater. 43, 3885 (2014).

M.O. Alam, Y.C. Chan, and K.C. Hung, Micro-electron. Reliabi. 42, 1065 (2002).

Lead Free Soldering Guide. AIM, https://pdfs.semanticscholar.org/7fce/45de57f95e1722cb9231e0fa5c92e 926ad4f.pdf

K.N. Chiang, Z.N. Liu, and C.T. Peng, in IEEE Transactions on Components and Packaging Technology, vol. 24, no. 4, (2001), pp. 635–640

S.P. Peng, W.H. Wu, C.E. Ho, and Y.M. Huang, J. Alloy. Compd. 493, 431 (2010).

T. Laurila, V. Vourinen, and J.K. Kivilahti, Mater. Sci. Eng. Rep. 49, 1 (2005).

J.W. Yoon, C.B. Lee, and S.B. Jung, Mater. Trans. 43, 1821 (2002).

C.E. Ho, S.W. Lin, and Y.C. Lin, J. Alloys Compd. 509, 7749 (2011).

H. Roberts and K. Johal, Lead-Free Board Surface Finishes. Lead-Free Soldering, ed. J. Bath (Boston: Springer, 2007)

Y.H. Cheng, G.D. Jenq, W.L. Chih, J.L. Chun, H.W. Yu, C.H. Huei, and H.W. Te, J. Mater. Sci. 48, 2724 (2013).

J.W. Yoon, B.I. Noh, and S.B. Jung, J. Electron. Mater. 40, 1950 (2011). https://doi.org/10.1007/s11664-011-1686-x.

K.P.L. Pun, N.S. Dhaka, C. Cheung, and A.H.S. Chan, J. Microelectron. Reliab. Microelectron. Reliab. 78, 339 (2017).

Automotive Electronics Council (AEC) standard, Component Technical Committee, AEC- Q100-010-Rev-A, July 18, (2003).

S.W. Chen, C.H. Wang, S.K. Lin, and C.N. Chiu, J. Mater. Sci. Mater. Electron. 18, 19 (2007).

J.I. Lee, S.W. Chen, H.Y. Chang, and C.M. Chen, J. Electron. Mater. 32, 117 (2003).

K.P.L. Pun, M.N. Islam, C. Cheung, and A.H.S. Chan, (2017). https://doi.org/10.1007/s10854-017-7086-0

B.J. Lee, N.M. Hwang, and H.M. Lee, Acta Mater. 45, 1867 (1997).

U.R. Kattner and W.J. Boettinger, J. Electron. Mater. 23, 603 (1994).

J.M. Kim, M.H. Jeong, S. Yeo, and Y.B. Kim, J. Electron. Mater. 41, 791 (2012).

S. Ahmed, Y.C. Chan, M.N. Islam, and M.J. Rizvi, J. Alloys Compd. 388, 75 (2005).

J.W. Yoon, S.W. Kim, and S.B. Jung, Mater. Trans. 45, 723 (2004).

Y. Jeon, K. Paik, K.S. Bok, W.S. Choi, and C.L. Cho, in 51st ECTC, (2001), pp. 1326–1332

W.R. Myung, Y. Kim, K.Y. Kim, and S.B. Jung, J. Electron. Mater. 45, 3651 (2016).

W. Dong, Y. Shi, Z. Xia, Y. Lei, and F. Guo, J. Electron. Mater. 37, 982 (2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pun, K.P.L., Islam, M.N., Rotanson, J. et al. Enhancement of Sn-Bi-Ag Solder Joints with ENEPIG Surface Finish for Low-Temperature Interconnection. J. Electron. Mater. 47, 5191–5202 (2018). https://doi.org/10.1007/s11664-018-6385-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-6385-4