Abstract

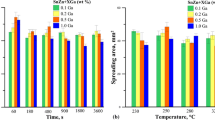

In this study the effect of Cr content (0.02 wt.% to 0.2 wt.%) on the wetting interaction between high-temperature Zn-25Sn-0.15Al-0.1Ga-xCr Pb-free solders and Cu has been investigated using the wetting balance method. Differential scanning calorimetry (DSC) investigation showed that Cr addition reduces the liquidus temperature slightly while raising the solidus temperature. Flux-assisted wetting experiments were carried out at an immersion rate of 15 mm/s at 435°C. The results show that the shortest wetting time of around 0.7 s was achieved when 0.1 wt.% Cr was added, but the wetting force tends to decrease with the Cr content. Cr addition enhances the formation of interfacial Cu5Zn8 intermetallic compound (IMC) during air cooling, but the opposite effect was observed for water cooling. The results suggest that Cr addition depresses the formation of the Cu5Zn8 layer in liquid/solid reaction, but enhances the formation of the Cu5Zn8 layer in solid/solid reaction.

Similar content being viewed by others

References

K. Suganuma, S.J. Kim, and K.S. Kim, High-Temperature Lead-Free Solders: Properties and Possibilities, 61, 64 JOM (2009).

J.E. Lee, K.S. Kim, K. Suganuma, M. Inoue, and G. Izuta, Mater. Trans. 48, 584 (2007).

J.E. Lee, K.S. Kim, K. Suganuma, J. Takenaka, and K. Hagio, Mater. Trans. 46, 2413 (2005).

R. Mahmudi and M. Eslami, J. Mater. Sci.: Mater. Electron. 22, 1168 (2011).

R. Mahmudi and M. Eslami, J. Electron. Mater. 39, 2495 (2010).

N.S. Liu and K.L. Lin, Oxid. Met. 78, 285 (2012).

N.S. Liu and K.L. Lin, Scripta Mater. 54, 219 (2006).

X. Chen, A. Hu, M. Li, and D. Mao, J. Alloys Compd. 460, 478 (2008).

G. Zhao, G. Sheng, J. Luo, and X. Yuan, J. Electron. Mater. 41, 2100 (2012).

S. Kim, K.S. Kim, K. Suganuma, and G. Izuta, J. Electron. Mater. 38, 873 (2009).

S. Kim, K.S. Kim, S.S. Kim, K. Suganuma, and G. Izuta, J.␣Electron. Mater. 38, 2668 (2009).

J. Bi, A. Hu, J. Hu, T. Luo, M. Li, and D. Mao, Microelectron. Reliab. 51, 636 (2011).

J. Hu, A. Hu, M. Li, and D. Mao, Mater. Charact. 61, 355 (2010).

Y.T. Wang, C.J. Ho, and H.L. Tsai, Mater. Trans. 51, 1735 (2010).

F.G. Yost, F.M. Hosking, and D.R. Frear, The Mechanics of Solder Alloy Wetting and Spreading (New York: Van Nostrand Reinhold, 1993), p. 148.

S.P. Yu, M.C. Wang, and M.H. Hon, J. Mater. Res. 16, 76 (2001).

C.W. Hwang, K.S. Kim, and K. Suganuma, J. Electron. Mater. 32, 1249 (2003).

W.Y. Lin (Master thesis, NCKU, 2011).

R. Abbaschian, L. Abbaschian, and R.E. Reed-Hill, Physical Metallurgy Principles (Stamford, CT: Cengage Learning, 2009), p. 267.

T.S. Chow, J. Phys.: Condens. Matter 10, 445 (1998).

Acknowledgements

Financial support of the present study from the National Science Council of the Republic of China under NSC101-2221-E-006-117-MY3 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, CW., Lin, KL. Effect of Cr Addition on Wetting Behavior Between Cu and High-Temperature Zn-25Sn-0.15Al-0.1Ga-xCr Pb-Free Solder. J. Electron. Mater. 43, 4502–4509 (2014). https://doi.org/10.1007/s11664-014-3449-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-014-3449-y