Abstract

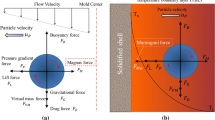

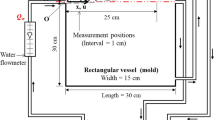

Euler–Euler simulations of transient horizontal gas–liquid flow in a continuous-casting mold are presented. The predictions were compared with previous experimental measurements by two-channel laser Doppler velocimeter. Simulations were performed to understand the sensitivity to different turbulence closure models [k–ɛ, shear stress transport (SST), Reynolds stress model (RSM), and large-eddy simulation (LES)] and different interfacial forces (drag, lift, virtual mass, wall lubrication, and turbulent dispersion). It was found that the LES model showed better agreement than the other turbulence models in predicting the velocity components of the liquid phase. Furthermore, an appropriate drag force coefficient model, lift force coefficient model, and virtual mass force coefficient were chosen. Meanwhile, the wall lubrication force and turbulent dispersion force did not have much effect on the current gas–liquid two-phase system. This work highlights the importance of choosing an appropriate bubble size in accordance with experiment. Finally, coupled with the optimized interfacial force models and bubble size, LES with a dynamic subgrid model was used to calculate the transient two-phase turbulent flow inside the mold. More instantaneous details of the two-phase flow characteristics in the mold were captured by LES, including multiscale vortex structures, fluctuation characteristics, and the vorticity distribution. The LES model can also be used to describe the time-averaged gas–liquid flow field, giving reasonably good agreement with mean experimental data. Thus, LES can be used effectively to study transient two-phase flow inside molds.

Similar content being viewed by others

Abbreviations

- C D :

-

Drag coefficient (dimensionless)

- C L :

-

Lift force model constant (dimensionless)

- C VM :

-

Virtual mass force model constant (dimensionless)

- C S :

-

Smagorinsky constant (dimensionless)

- C TD :

-

Turbulent dispersion model constant (dimensionless)

- C WL :

-

Wall lubrication force model constant (dimensionless)

- C μ,BI :

-

Sato and Sekiguchi model constant (dimensionless)

- C ω1, C ω2 :

-

Wall lubrication constants (dimensionless)

- d b :

-

Bubble diameter (m)

- D T,ij :

-

Turbulent diffusion term of Reynolds stress model

- Eo:

-

Eötvös number (dimensionless)

- F 1, F 2 :

-

Blending functions (dimensionless)

- Fr:

-

Froude number (dimensionless)

- F k , F 1g, F gl :

-

Interfacial forces between the two phases (N/m3)

- F D :

-

Drag force (N/m3)

- F L :

-

Lift force (N/m3)

- F VM :

-

Virtual mass force (N/m3)

- F WL :

-

Wall lubrication force (N/m3)

- F TD :

-

Turbulent dispersion force (N/m3)

- g :

-

Gravity acceleration vector (m/s2)

- G k :

-

Rate of production of turbulent kinetic energy (dimensionless)

- k :

-

Turbulent kinetic energy (m2/s2)

- \( \vec{n}_{\text{w}} \) :

-

Outward vector normal to the wall (dimensionless)

- P :

-

Static pressure (N/m2)

- P ij :

-

Stress production term of Reynolds stress model

- P k :

-

Production rate of turbulence (dimensionless)

- Q :

-

Volume flow rate (m3/s)

- Re :

-

Reynolds number (dimensionless)

- S :

-

Strain rate tensor (1/s)

- t :

-

Physical time (s)

- u :

-

Velocity (m/s)

- We:

-

Weber number (dimensionless)

- y ω :

-

Distance from the wall boundary (m)

- α :

-

Volume fraction (dimensionless)

- β :

-

Constant (dimensionless)

- ρ :

-

Density (kg/m3)

- ε :

-

Turbulent kinetic energy dissipation (m2/s3)

- μ eff :

-

Effective viscosity (N s/m2)

- μ L :

-

Molecular viscosity (N s/m2)

- μ T :

-

Turbulent viscosity (N s/m2)

- υ :

-

Kinematic viscosity (m2/s)

- μ BI :

-

Bubble-induced turbulence viscosity (N s/m2)

- σ :

-

Surface tension (N/m)

- σ t,g :

-

Turbulent Schmidt number (dimensionless)

- τ :

-

Stress (N/m2)

- δ :

-

Kronecker factor (dimensionless)

- ϕ ij :

-

Pressure strain term of Reynolds stress model

- ψ ij :

-

Dissipation term of Reynolds stress model

- ω :

-

Turbulent frequency (1/s)

- ω′:

-

Angular speed of liquid rotation (rad/s)

- Ω :

-

Vorticity (1/s)

- ∆ :

-

Filter width (m)

- b:

-

Bubble

- g:

-

Gas phase

- k :

-

Index of gas/liquid phase, or turbulent kinetic energy

- l:

-

Liquid phase

References

M. Iguchi and N. Kashi: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 453–60.

B.G. Thomas, L.J. Mika, and F.M. Najjar: Metall. Mater. Trans. B, 1990, vol. 21B, pp. 387–400.

A. Ramos-Banderas, R.D. Morales, R. Sanchez-Perez, L. Garcia-Demedices, and G. Solorio-Diaz: Int. J. Multiphase Flow, 2005, vol. 31, pp. 643–65.

Z.Q. Liu, F.S. Qi, B.K. Li, and S.C.P. Cheung: Int. J. Multiphase Flow, 2016, vol. 79, pp. 190–201.

E. Krepper, D. Lucas, and H.M. Prasser: Nucl. Eng. Des., 2005, vol. 235, pp. 597–611.

S.C.P. Cheung, G.H. Yeoh, and J.Y. Tu: Chem. Eng. Sci., 2007, vol. 62, pp. 4659–74.

M.T. Dhotre, B. Niceno, and B.L. Smith: Chem. Eng. J., 2008, vol. 136, pp. 337–48.

M.V. Tabib, S.A. Roy, and J.B. Joshi: Chem. Eng. J., 2008, vol. 139, pp. 589–614.

N.G. Deen, T. Solberg, and B.H. Hjertager: Chem. Eng. Sci., 2001, vol. 56, pp. 6341–49.

D.S. Zhang, N.G. Deen, and J.A.M. Kuipers: Ind. Eng. Chem. Res., 2009, vol. 48, pp. 47–57.

B.G. Thomas, Q. Yuan, S. Mahmood, R. Liu, and R. Chaudhary: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 22–35.

S.M. Lee, S.J. Kim, and H.G. Lee: J. Iron Steel Res. Int., 2011, vol. 18, pp. 220–26.

Y. Miki and S. Takeuchi: ISIJ Int., 2003, vol. 43, pp. 1548–55.

Z.Q. Liu and B.K. Li: Powder Technol., 2016, vol. 287, pp. 315–29.

Z.Q. Liu, B.K. Li, and M.F. Jiang: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 675–97.

H. Bai and B.G. Thomas: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 253–67.

Z.Q. Liu, B.K. Li, M.F. Jiang, and F. Tsukihashi: ISIJ Int., 2013, vol. 53, pp. 484–92.

Z.Q. Liu, B.K. Li, M.F. Jiang, and F. Tsukihashi: ISIJ Int., 2014, vol. 54, pp. 1314–23.

A. Ramos-Banderas, R. Sánchez-Perez, R.D. Morales, J. Palafox-ramos, L. Demedices-Garcia, and M. Diaz-cruz: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 449–60.

Q. Yuan, S. Sivaramkrishnan, S.P. Vanka, and B.G. Thomas: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 967–82.

Z.Q. Liu, F.S. Qi, B.K. Li, and M.F. Jiang: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 933–52.

H.A. Jakobsen, B.H. Sannaes, S. Grevskott, and H.F. Svendsen: Ind. Eng. Chem. Res., 1997, vol. 36, pp. 4052–74.

Y. Sato, M. Sadatomi, and K. Sekiguchi: Int. J. Multiphase Flow, 1975, vol. 2, pp. 79–87.

F.R. Menter: AIAA J, 1994, vol. 32, pp. 1598–1605.

J. Smagorinsky: Month. Weather Rev., 1963, vol. 91, pp. 99–165.

D. Lakehal, B.L. Smith, and M. Milelli: J. Turb., 2002, vol. 3, pp. 1–20.

M. Germano, U. Piomelli, P. Moin, and W.H. Cabot: Phys. Fluids A, 1991, vol. 3, pp. 1760–65.

D.K. Lilly: Phys. Fluids A, 1992, vol. 4, pp. 633-35.

D.A. Drew and R.T. Lahey: Int. J. Multiphase Flow, 1987, vol. 13, pp. 113–21.

D.Z. Zhang and W.B. Vanderheyden: Int. J. Multiphase Flow, 2002, vol. 28, pp. 805–22.

A. Tomiyma, H. Tamai, I. Zun, and S. Hosokawa: Chem. Eng. Sci., 2002, vol. 57, pp. 1949–58.

M. Ishii and N. Zuber: AIChE J, 1979, vol. 25, pp. 843-55.

L.A. Schiller and Z. Naumaan: Ver Deutsch. Ing., 1935, vol. 77, 138 pp.

P. G. Saffman: J. Fluid Mech., 1965, vol. 22, pp. 385-400.

R. Mei and J. F. Klausner: Int. J. Heat Fluid Flow, 1994, vol. 15, pp. 62–65.

D. Legendre and J. Magnaudet: J. Fluid Mech., 1998, vol. 368, pp. 81–126.

S.S. Thakre and J.B. Joshi: Chem. Eng. Sci., 1999, vol. 54, pp. 5055–60.

A. Sokolichin and G. Eigenberger: AIChE J, 2004, vol. 50, pp. 24-45.

S.P. Antal, R.T. Lahey, and J.E. Flaherty: Int. J. Multiphase Flow, 1991, vol. 7, pp. 635–52.

T. Frank, P. Zwart, E. Krepper, H.M. Prasser, and D. Lucas: Nucl. Eng. Des., 2008, vol. 238, pp. 647–59.

M. Lopez de Bertodano: Ph.D. Thesis, Rensselaer Polytechnic Institute, Troy, 1991.

A.D. Burns, T. Frank, I. Hamill, and J. Shi: Proceeding of the Fifth International Conference on Multiphase Flow, Yokohama, Japan. 2004.

B.G. Thomas, Q. Yuan, S. Sivaramakrishnan, T. Shi, S.P. Vanka, and M.B. Assar: ISIJ Int., 2001, vol. 41, pp. 1262–71.

K. Timmel, T. Wondrak, M. Roder, F. Stefani, S. Eckeert, and G. Gerbeth: Steel Res. Int., 2014, vol. 85, pp. 1283–90.

Acknowledgments

The work reported in this paper was funded by the National Natural Science Foundation of China (Grant No. 51604070).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 16, 2016.

Rights and permissions

About this article

Cite this article

Liu, Z., Li, B. Large-Eddy Simulation of Transient Horizontal Gas–Liquid Flow in Continuous Casting Using Dynamic Subgrid-Scale Model. Metall Mater Trans B 48, 1833–1849 (2017). https://doi.org/10.1007/s11663-017-0947-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-017-0947-3