Abstract

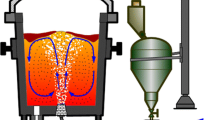

A process model for basic oxygen furnace (BOF) steel converter is in development. The model will take into account all the essential physical and chemical phenomena, while achieving real-time calculation of the process. The complete model will include a 2D axisymmetric turbulent multiphase flow model for iron melt and argon gas mixture, a steel scrap melting model, and a chemical reaction model. A novel liquid mass conserving mixture multiphase model for bubbling gas jet is introduced in this paper. In-house implementation of the model is tested and validated in this article independently from the other parts of the full process model. Validation data comprise three different water models with different volume flow rates of air blown through a regular nozzle and a porous plug. The water models cover a wide range of dimensionless number \( R_{\text{p}} \), which include values that are similar for industrial-scale steel converter. The k–ε turbulence model is used with wall functions so that a coarse grid can be utilized. The model calculates a steady-state flow field for gas/liquid mixture using control volume method with staggered SIMPLE algorithm.

Similar content being viewed by others

Abbreviations

- ρ :

-

Density (kg m−3)

- V :

-

Velocity vector (m s−1)

- u,v :

-

Radial and axial velocity components (m s−1)

- α :

-

Phase fraction

- p :

-

Pressure (Pa)

- g :

-

Gravity vector (m s−2)

- τ :

-

Stress tensor

- c :

-

Mass fraction

- D :

-

Diffusion coefficient (m2 s−1)

- Ω:

-

Volume (m3)

- \( \varvec{V}_{{{\text{cd}}\infty }} \) :

-

Bubble terminal velocity (m s−1)

- \( A_{\text{CS}} \) :

-

Bubble cross-section area (m2)

- \( C_{\text{D}} \) :

-

Drag coefficient

- d :

-

Diameter (m)

- Re :

-

Reynolds number (dimensionless)

- Mo :

-

Morton number (dimensionless)

- μ :

-

Viscosity (Pa s)

- \( N_{\mu } \) :

-

Fourth root of Morton number (dimensionless)

- σ :

-

Surface tension (N/m)

- k :

-

Turbulence kinetic energy (m2 s−2)

- P :

-

Turbulence production due to shear flow

- \( {\textit{P}}_{{{\text{b}}k}} \) :

-

Turbulence production due to bubbles

- ε :

-

Turbulence dissipation rate (m2 s−3)

- \( C_{\text{f}} \) :

-

Bubble friction coefficient

- S :

-

Surface area (m2)

- r,z :

-

Radial and axial coordinate (m)

- n :

-

Surface unit normal vector

- ϖ:

-

Weighing factor

- M :

-

Molar mass (mol/kg)

- R :

-

Molar gas constant (J mol−1 K−1)

- T :

-

Temperature (K)

- \( c_{\rho } \) :

-

Conversion coefficient from pressure to density (s2 m−2)

- R :

-

Explicit residual vector

- A :

-

Coefficient matrices for the system of equations

- J :

-

Nozzle momentum source (kg m s−2)

- \( \dot{m} \) :

-

Mass flux (kg s−1)

- \( A_{\text{nozzle}} \) :

-

Nozzle area (m2)

- K :

-

Nozzle turbulence kinetic energy source (kg m2 s−3)

- t :

-

Time (s)

- C :

-

Courant number (dimensionless)

- \( C^{\text{vis}} \) :

-

Visous number (dimensionless)

- ω :

-

Volume ratio (dimensionless)

- Q :

-

Volume flow rate (m3 s−1)

- \( d_{\text{nozzle}} \) :

-

Nozzle diameter (m)

- H :

-

Bath height (m)

- \( R_{\text{p}} \) :

-

Plume momentum ratio (dimensionless)

- \( k - \varepsilon \) :

-

Turbulence model constants

- σ k :

-

= 1.0

- σ ε :

-

= 1.3

- C μ :

-

= 0.09

- C ε1 :

-

= 1.44

- C ε2 :

-

= 1.92

- C ε3 :

-

= 1.825

- C k1 :

-

= 1.0

- m:

-

Mixture

- c:

-

Continuous phase

- d:

-

Dispersed phase

- T:

-

Turbulence

- D:

-

Diffusion

- b:

-

Bubble

- p:

-

Particle

- eff:

-

Effective

- \( {\text{n}},{\text{e}},{\text{s}},{\text{w}},{\text{p}} \) :

-

north, east, south, west, middle cell

- i,j :

-

Grid coordinate directions

- tot:

-

Total

- a:

-

Air

- i :

-

Initial value

- g:

-

Gas

- l:

-

Liquid

- n :

-

Time level index

- *:

-

Updated velocity value after momentum equation

- ‘:

-

Fluctuation of variable also used in pressure-correction algorithm as a correction

- L, R:

-

Left, right

- T:

-

Transpose

- p :

-

Pressure matrix

- V :

-

Momentum equation matrix

References

D. Mazumdar and R.I.L. Guthrie, ISIJ Int., 1995, Vol. 35, pp. 1–20.

H.A. Jakobsen, B.H. Sannaes, S. Grevskott and H.F. Svendsen, Ind. Eng. Chem. Res., 1997, Vol. 36, pp. 4052–74.

T. Deb Roy, A.K. Majumdar and D.B. Spalding, Appl. Math. Model., 1978, Vol. 2, pp. 146–50.

J.H. Grevet, J. Szekely and N. El-Kaddah, Int. J. Heat Mass Transf., 1982, Vol. 25, pp. 487–97.

Y. Sahai and R.I.L. Guthrie, Metal. Trans. B, 1982, Vol. 13, pp. 203–11.

M. Salcudean, C.H. Low, A.H. Hurda and R.I.L. Guthrie, Chem. Eng. Commun., 1982, Vol. 21, pp. 89–103

D. Mazumdar and R.I.L. Guthrie, Metal. Trans. B, 1982, 13B, pp. 83–90

J.W. McKelliget, M. Cross and R.D. Gibson, Appl. Math. Model., 1982, Vol. 6, pp. 469–80.

A.H. Castillejos, M.E. Salcudean and J.K. Brimacombe, Metal. Trans. B, 1989, Vol. 20B, pp. 603–11.

D. Mazumdar and R.I.L. Guthrie, Steel Res., 1993, Vol. 64, pp. 286–91.

Y.Y. Sheng and G.A. Irons, Metal. Trans. B, 1993, Vol. 24, 695–705.

M.-Y. Zhu, T. Inomoto, I. Sawada and T.-C. Hsiao, ISIJ Int., 1995, Vol. 35, pp. 472–79.

S. Taniguchi, S. Kawaguchi and A. Kikuchi: Proc of CSIRO, Melbourne, Australia. 1999, pp. 193–98.

S. Taniguchi, S. Kawaguchi and A. Kikuchi, Appl. Math. Model., 2002, Vol. 26, pp. 249–62.

S.T Johansen and F. Boysan, Metal. Trans. B, 1988, Vol. 19, pp. 755–64.

D. Mazumdar and R.I.L. Guthrie, ISIJ Int., 1994, Vol. 34, pp. 384–92.

Y.Y. Sheng and G.A. Irons, Metal. Mater. Trans. B, 1995, Vol. 26B, pp. 625–35.

D. Guo and G.A. Irons, Metal. Mater. Trans. B, 2000, Vol. 31B, pp. 1457–64.

D.C. Guo, L. Gu and G.A. Irons, Appl. Math. Model., 2002, Vol. 26, pp. 263–80.

J. Aoki, L. Zhang and B.G. Thomas: Proc. of Science and Technology of Steelmaking, Charlotte, NC, 2005, pp. 319–32.

M.P. Schwarz and W.J. Turner, Appl. Math. Model., 1988, Vol. 12, pp. 273–79.

M.R. Davidson, Appl. Math. Model., 1990, Vol. 14, pp. 67–76.

O.J. Ilegbusi and J. Szekely, ISIJ Int., 1990, Vol. 30, pp. 731–39.

H. Turkoglu and B. Farouk, Metal. Trans. B, 1990, Vol. 21, pp. 771–81.

H. Turkoglu and B. Farouk, ISIJ Int., 1990, Vol. 30, pp. 961–70.

H. Turkoglu and B. Farouk, ISIJ Int., 1991, Vol. 31, pp. 1371–80.

O.J. Ilegbusi and J. Szekely, M. Iguchi, H. Takeuchi and Z.-I. Morita, ISIJ Int., 1993, Vol. 33, pp. 474–78.

M.P. Schwarz, Appl. Math. Model., 1996, Vol. 20, pp. 41–51.

B.L. Smith, Appl. Math. Model., 1998, Vol. 22, pp. 773–97.

O.J. Ilegbusi, M. Iguchi, K. Nakajima, M. Sano and M. Sakamoto, Metal. Mater. Trans. B, 1998, Vol. 29B, pp. 211–22.

J. Hua and C.-H. Wang, Chem. Eng. Sci., 2000, Vol. 55, pp. 4159–73.

L. Zhang, Modell. Simul. Mater. Sci. Eng., 2000, Vol. 8, pp. 463–76.

M. L. de Bertodano, F.J. Moraga, D.A. Drew and R.T. Lahey, J. Fluids Eng., 2004, Vol. 126, pp. 573-77.

R. Zboray and F. Cachard, Nucl. Eng. Des., 2005, Vol. 235, pp. 867–84.

C. G. Mendez, N. Nigro and A. Cardona, J. Mater. Process. Technol., 2005, Vol. 160, pp. 296–305.

A. Kruskopf, Metall. Mater. Trans. B, 2015, Vol. 46B, Issue 3, pp. 1195–206.

A. Kruskopf and S. Louhenkilpi: Proc. of METEC & 2nd ESTAD, Düsseldorf Germany, 2015, P165.

M. Manninen and V. Taivassalo: Report No. 288, VTT Publications, Technical Research Center of Finland, 1996.

M. Ishii and T. Hibiki, Thermo-Fluid Dynamics of Two-phase Flow, 2nd ed., Springer, New York, 2011, pp. 334–42.

Y. Sato, and M. Sadatomi, Int. J. Multiph. Flow, 1981, Vol. 7, pp. 167–77.

G.D Van Albada, B. van Leer and W.W. Roberts, Astron. Astrophys., 1982, Vol. 108, pp. 76–84.

D.C. Wilcox, Turbulence Modeling for CFD, DCW Industries Inc., California, 1994, pp. 291.

S.V. Patankar, Numerical Heat Transfer and Fluid Flow, Hemisphere Publishing Corporation, New York, 1980, pp. 126–30.

J.H. Ferziger and M. Perić, “Computational Methods for Fluid Dynamics”, 3rd ed., Springer-Verlag, Berlin, 2002 pp. 313.

M. Iguchi, H. Takeuchi and Z. Morita, ISIJ Int., 1991, Vol. 31, pp. 246–53.

M. Iguchi, T, Kondoh, Z. Morita, K. Nakajima, K. Hanazaki, T. Uemura and F. Yamamoto, Metall. Mater. Trans. B, 1995, Vol. 26B, pp. 241-47.

S.T. Johansen, D.G.C. Robertson, K. Woje and T.A. Engh, Metal. Trans. B, 1988, Vol. 19, pp. 745–54.

K. Krishnapisharody and G.A Irons, Metall. Mater. Trans. B, 2013, Vol. 44B, pp. 1486–498.

H. Jalkanen and L. Holappa, Treatise on Process Metallurgy Volume 3 Part A, Elsevier Ltd, Amsterdam, 2014, pp. 244.

Acknowledgments

This work was partly funded by the Finnish Funding Agency for Technology and Innovation (TEKES). The research was carried out as part of the Finnish Metals and Engineering Competence Cluster (FIMECC)’s SIMP 2.1 subprogram. This research was also supported by a grant from Technology Industries of Finland Centennial Foundation Fund for the Association of Finnish Steel and Metal Producers.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 24, 2016.

Rights and permissions

About this article

Cite this article

Kruskopf, A. A 2D Axisymmetric Mixture Multiphase Model for Bottom Stirring in a BOF Converter. Metall Mater Trans B 48, 619–631 (2017). https://doi.org/10.1007/s11663-016-0856-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0856-x