Abstract

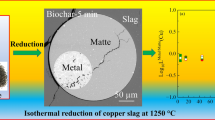

In steelmaking process, quicklime is used to produce CaO-based slag. Although rapid dissolution of quicklime is required for high-efficiency refining, it is known that the rate decreases when dicalcium silicate (C2S) layer forms around the quicklime by reacting with slag. The equation that driving force is the difference of CaO content between in slag and a liquid phase of slag saturated by C2S has been often used for estimating the dissolution rate of lime, in which this saturated value is thermodynamically determined. The authors, however, revealed that the quicklime used in actual operation showed much faster dissolving rate than that of completely calcined lime that is covered by C2S layer during dissolution into slag. This was caused by a gas formation due to a thermal decomposition of residual limestone existed in quicklime. In this study, the dissolution rate of quicklime with the gas formation is quantitatively investigated.

Similar content being viewed by others

References

J. Yang, M. Kuwabara, T. Asano, A. Chuma, and J. Du: ISIJ Int., 2007, vol. 47, pp. 1401-1408.

Y. Satyoko and W.E. Lee: Br. Ceram. Trans., 1999, vol. 98, pp. 261-265.

S. Amini, M. Brungs, and O. Ostrovski: ISIJ Int., 2007, vol. 47, pp. 32-37.

N. Dogan, G.A. Brooks, and M.A. Rhamdhani: ISIJ Int., 2009, vol. 49, pp. 1474-1482.

S. Kitamura, H. Shibata, and N. Maruoka: High Temp. Mater. Process., 2012, vol. 31, pp. 195-201.

Y. Ogawa and N. Maruoka: Tetsu to Hagane, 2014, vol. 100, pp. 434-444.

Y. Wang, X. Guo, B. Xie, J. Diao, and G.E. Wang: J. Iron Steel Res., 2011, vol. 23, pp. 8-10+33.

A.K. Hewage, G. Brooks, and J. Naser: AISTech – Iron and Steel Technology Conference Proceedings, 2015, pp. 3745-52.

B.K. Rout, G.A. Brooks, Z. Li, and M.A. Rhamdhani: AISTech – Iron and Steel Technology Conference Proceedings, 2015, pp. 3225-37.

10. M. Matsushima, S. Yadoomaru, K. Mori and Y. Kawai, Trans. ISIJ, 1977, vol. 17, pp. 442-449.

M. Umakoshi, K. Mori, and Y. Kawai: Trans. ISIJ, 1984, vol. 24, pp. 532-539.

S. Taira, K. Nakashima, and K. Mori: Tetsu-to-Hagane, 1995, vol. 81, pp. 16-21.

T. Hamano, M. Horibe, and K. Ito: ISIJ Int., 2004, vol. 44, pp. 263-267.

S. Jansson, V. Brabie, and P. Jönsson: Ironmaking Steelmaking, 2006, vol. 33, pp. 389-397.

W. Yan, W. Chen, Y. Yang, X. Zhao, and A. McLean: AISTech 2015 Iron and Steel Technology Conference and 7th International Conference on the Science and Technology of Ironmaking, ICSTI 2015, Association for Iron and Steel Technology, AISTECH, 2015, pp. 2162-72.

F. Pahlevani, S. Kitamura, H. Shibata, and N. Maruoka: Steel Res. Int., 2010, vol. 81, pp. 617-622.

S.-y. Kitamura, F. Pahlevani, N. Maruoka, and H. Shibata: High Temperature Processing Symposium 2011, 2011.

N. Dogan, G.A. Brooks, and M.A. Rhamdhani: ISIJ Int., 2011, vol. 51, pp. 1086-1092.

A. Harada, N. Maruoka, H. Shibata, and S. Kitamura: ISIJ Int., 2013, vol. 53, pp. 2110-2117.

A. Harada, N. Maruoka, H. Shibata, and S. Kitamura: ISIJ Int., 2013, vol. 53, pp. 2118-25.

A. Harada, N. Maruoka, H. Shibata, M. Zeze, N. Asahara, F.X. Huang, and S. Kitamura: ISIJ Int., 2014, vol. 54, pp. 2569-2577.

A. Harada, G. Miyano, N. Maruoka, H. Shibata, and S. Kitamura: ISIJ Int., 2014, vol. 54, pp. 2230-2238.

T.F. Deng and S.C. Du, Metall. Mater. Transactions B-Process Metallurgy and Materials Processing Science, 2012, vol. 43, pp. 578-586.

24. N. Maruoka, A. Ishikawa, H. Shibata and S. Kitamura, High Temp. Mater. Processes, 2013, vol. 32, pp. 15-24.

25. Nobuhiro Maruoka, Akira Ishikawa, Hiroyuki Shibata and Shin-ya Kitamura, Journal of the Technical Association of Refractories, Japan (TAIKABUTSU OVERSEAS), 2015, vol. 34, pp. 3-9.

N. Maruoka, A. Ishikawa, H. Shibata, and S.-y. Kitamura: 12th Biennial Worldwide Conference on Refractories, UNITECR 2011, Kyoto, 2011, pp. 590-93.

N. Maruoka, J. Liu, H. Shibata, and S.-y. Kitamura: 5th Baosteel Biennial Academic Conference, Shanghai, 2013, pp. B116-20.

F. Huang, J. Liu, N. Maruoka, S.-y. Kitamura, and A. Ishikawa: Int. J. Appl. Ceram. Technol., 2015, vol. 12, pp. 1239-44.

N. Maruoka and H. Nogami: AISTech 2015 Iron and Steel Technology Conference (AISTech 2015), Association for Iron and Steel Technology, AISTECH, Cleveland, 2015, pp. 2117-24.

H. Li, L.F. Guo, Y.Q. Li, W.C. Song, J. Feng, M. Liang, D.X. Dong, G.L. Wang, H. W. Zhang, S.L. Li, and T.F. Zhang, Advanced Materials Research, 2011, vol. 233-35, pp. 2644-2647

31. B. Tang, X. M. Wang, Z. S. Zou, and A. B. Yu, Dongbei Daxue Xuebao, 2014, vol. 35, pp. 534-538.

32. T. F. Deng, P. Nortier, M. Ek, and S. Du, Metallurgical and Materials Transactions B-Process Metallurgy and Materials Processing Science, 2013, vol. 44, pp. 98-105.

33. Nobuhiro Maruoka, Akira Ishikawa, Hiroyuki Shibata, and Shin-ya Kitamura, TAIKABUTSU, 2013, vol. 65, pp. 161-167.

Slag Atlas, 2nd ed., Verlag Stahleisen GmbH, Düsseldorf, 1995.

Acknowledgments

This study was supported by the 23rd ISIJ Research Promotion Grant. We are grateful to all the members of the ISIJ research committee in Slag formation with high-speed lime dissolution for helpful discussions. Quicklime used in this study was supplied from Yoshizawa Lime Industry Co., Ltd. The authors also acknowledge Mr. A. Ito and Ms. M. Hayasaka at Tohoku University for their experimental assistance and Professor Kitamura at Tohoku University for allowing us to use experimental equipment and for useful discussion.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 29, 2015.

Rights and permissions

About this article

Cite this article

Maruoka, N., Nogami, H. Rapid Dissolution of Quicklime into Molten Slag by Internally Formed Gas. Metall Mater Trans B 48, 113–118 (2017). https://doi.org/10.1007/s11663-016-0741-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0741-7