Abstract

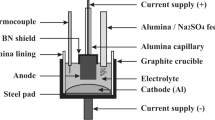

Anode impurities are the major source of sulfur in aluminum electrolysis. Sulfur in anodes is mainly found as organic compounds. Alumina also introduces small quantities of sulfur, typically in the form of sulfates. The scarcity and cost of low-sulfur raw materials and the possibility of sulfur removal from the cell by means of flue gas may make high-sulfur content anodes a viable option. However, some anode impurities are known to affect current efficiency in aluminum production and caution must be exercised. The effect of increased sulfur content in the aluminum electrolysis electrolyte must be studied. This paper explores the effect of increased sulfur concentration in the electrolyte on current efficiency in a laboratory cell. Sodium sulfate was added to the electrolyte as a source of sulfur at regular time intervals to maintain a constant sulfur concentration. Current efficiency decreased by 1.1 pct per each 100 mg/kg (ppm) increase in sulfur concentration in the electrolyte.

Similar content being viewed by others

References

H. Kvande and P. A. Drabløs: JOEM, 2014, vol. 56, no. 5S, pp. S23–S32.

M. Tangstad (ed): Metal Production in Norway. Akademika, Trondheim, 2013, p. 50.

J. Thonstad, P. Fellner, G.M. Haarberg, J. Híveš, H. Kvande, and Å. Sterten: Aluminum electrolysis – Fundamentals of the Hall-Héroult process, 3rd ed., Aluminum-Verlag GmbH, Düsseldorf, Germany, 2001.

A. Solheim: Light Metals 2014. The Minerals, Metals & Materials Society (TMS), Warrendale, PA, pp. 753–758.

K. Grjotheim, C. Krohn, M. Malinovsky, K. Matiasovsky, and J. Thonstad: Aluminum electrolysis – Fundamentals of the Hall-Héroult process, 2nd ed., Aluminum-Verlag GmbH, Düsseldorf, Germany, 1992.

Å. Sterten, P.A. Solli, and E. Skybakmoen: J. Appl. Electrochem., 1998, 28, pp. 781-789.

P.A. Solli: Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, 1993, ISBN: 82-7119-477-1.

E.W. Thisted: Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, 2003, ISBN: 82-471-5603-2.

Å. Sterten, P.A. Solli and E. Skybakmoen: J. Appl. Electrochem., 1997, 28, pp. 781–789.

M.G. Escard and G.M. Haarberg, eds.: Molten Salts Chemistry and Technology, Wiley, New York, 2014, pp. 71–75.

R. Meirbekova, J. Thonstad, G.M. Haarberg, and G. Saevarsdottir: Light Metals 2014. The Minerals, Metals & Materials Society (TMS), Warrendale, PA, 2014, pp. 759–764.

J. Hajasova: Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, 2007.

M. Sørlie, Z. Kuang, and J. Thonstad: Light Metals 1994. The Minerals, Metals & Materials Society (TMS), Warrendale, PA, 1994, pp. 659–665.

H. Kuang, J. Thonstad, and M.Sørlie: Carbon, 1995, N10, vol. 33, pp. 1479–1484

T. Eidet, M. Sørlie, and J. Thonstad: Light Metals 1997. The Minerals, Metals & Materials Society (TMS), Warrendale, PA, 1997, pp. 511–517.

M. Sørlie and T. Eidet: Light Metals 1998. The Minerals, Metals & Materials Society (TMS), Warrendale, PA, 1998, pp. 763–768.

L. Edwards: JOM, 2014, vol. 67, no. 2, pp. 308-321

V.L. Bullough, H.C. Marshall, and C.J. McMinn: Light Metals. The Minerals, Metals & Materials Society (TMS), Warrendale, PA, 1971, pp. 411–423.

E. Barillon and J. Pinnon: Light Metals. The Minerals, Metals & Materials Society (TMS), Warrendale, PA, 1977, pp. 289–299.

G.P. Gilmore and V.L. Bullough: Light Metals. The Minerals, Metals & Materials Society (TMS), Warrendale, PA 1982, pp. 741–752.

S. Pietrzik and J. Thonstad: Light Metals 2012. The Minerals, Metals & Materials Society (TMS), Warrendale, PA, 2012, pp. 659–664.

S.S. Jones, R.D. Hildebrandt, and M.C. Hedlund: Light Metals 1979. The Minerals, Metals & Materials Society (TMS), Warrendale, PA, 1979, vol. 2, pp. 553–574.

R.J. Thorne, C. Sommerseth, E. Sandnes, O. Kjos, T.A. Aarhaug, L.P. Lossius, H. Linga, and A.P. Ratvik: Light Metals 2013. The Minerals, Metals & Materials Society (TMS), Warrendale, PA, 2013, pp. 1207–1211.

R.J. Thorne, C. Sommerseth, A.M. Svensson, E. Sandnes, L.P. Lossius, H. Linga, and A.P. Ratvik: Light Metals 2014. The Minerals, Metals & Materials Society (TMS), Warrendale, PA, 2014, pp. 1213–1217.

K. Grjotheim, T. Halvorsen, and S. Urnes, Can. J. of Chem., 1959, 37, pp. 1170-1175.

I. Koštenská and M. Malinovský: Chem. Zvesti, 1982, 36, pp. 159-167.

V. Danielik, J. Gabčová: Thermochimica Acta, 2001, 366, pp. 79-87

P. Fellner, J. Gabčová, V. Danielik, and M. Laska: Chem Papers, 1993, vol. 47(4), pp. 215–217.

K. Matiašovský and M. Malinovský: Chem. Zvesti, 1965, 19, pp. 41-45.

V.V. Burnakin, R.K. Popkova, V.I. Zalivnoy, P.V. Polyakov, and V.I. Kolosova: Sov J Non-Ferrous Met Res, 1982, vol. 2(4), pp. 282-285.

M.B. Shvartsberg, Trudy VAMI, 1937, N14, 113.

Yu.V. Baimakov, and M.M. Vetykov, Molten salts Electrolysis, Metallurgiya, Moscow, 1966.

M. Ambrová, P. Fellner, J. Gabcova, and A. Sykorova (2005) Chem. Papers-Slovak Academ Sci., vol. 4, no. 59, pp. 235-239.

N.Q. Minh and N.P. Yao: J. Electrochem. Soc., 1984, vol. 131, No. 10, pp. 2279–2282.

R. Meirbekova, G. M. Haarberg, J. Thonstad, T. A. Aarhaug and G. Saevarsdottir: ECS Transactions, 2015, vol 69, no. 15, pp. 13-23.

P. A. Solli, T. Haarberg, T. Eggen, E. Skybakmoen and Å. Sterten: Light Metals, TMS, Warrendale, PA 1994, pp. 195-203.

Acknowledgments

This work was supported by Alcoa Fjarðaál, HRV Engineering, SINTEF, and NTNU. Authors would like to thank Ms. Anne Tofte for her invaluable contribution to this work. Authors would also like to express endless gratitude to Dr. Andrei Manolescu, Dr. Arne P. Ratvik, Dr. Thor A. Aarhaug, Dr. Ole S. Kjos, Mr. Asbjørn Solheim, and Dr. Marketa Valterova for their comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 8, 2015.

Rights and permissions

About this article

Cite this article

Meirbekova, R., Haarberg, G.M., Thonstad, J. et al. Influence of Sulfur Species on Current Efficiency in the Aluminum Smelting Process. Metall Mater Trans B 47, 1309–1314 (2016). https://doi.org/10.1007/s11663-016-0595-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0595-z